Damping adjustment rotating shaft mechanism for washing machine cover plate

A washing machine cover and damping adjustment technology, which is applied to other washing machines, applications, pivots, etc., can solve the problems of difficult cooperation between the cover plate assembly and the surface frame, inconvenient operation, and poor mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

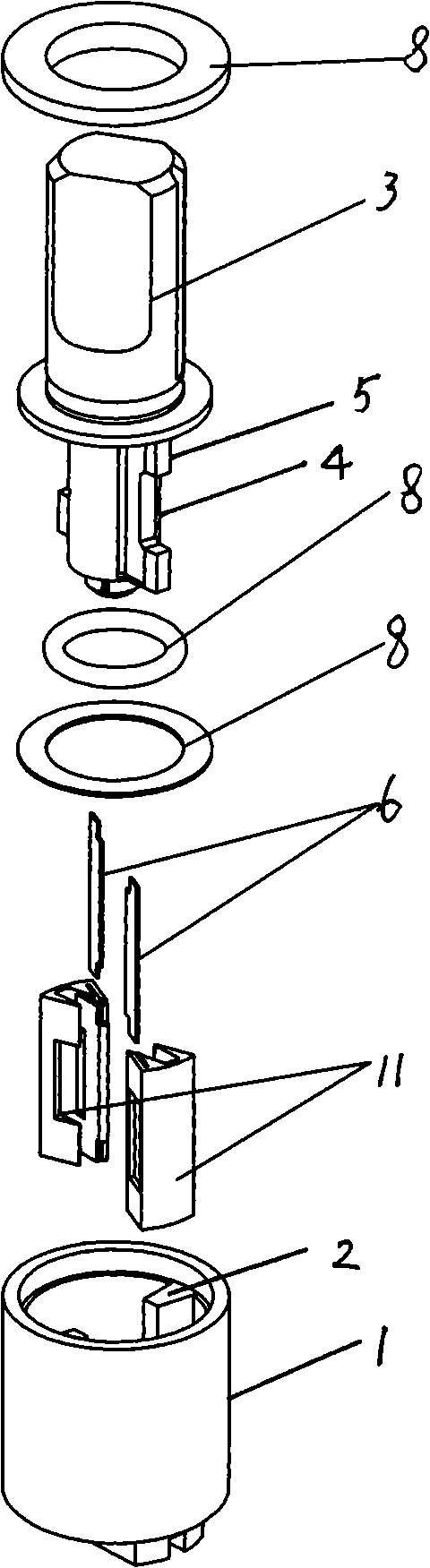

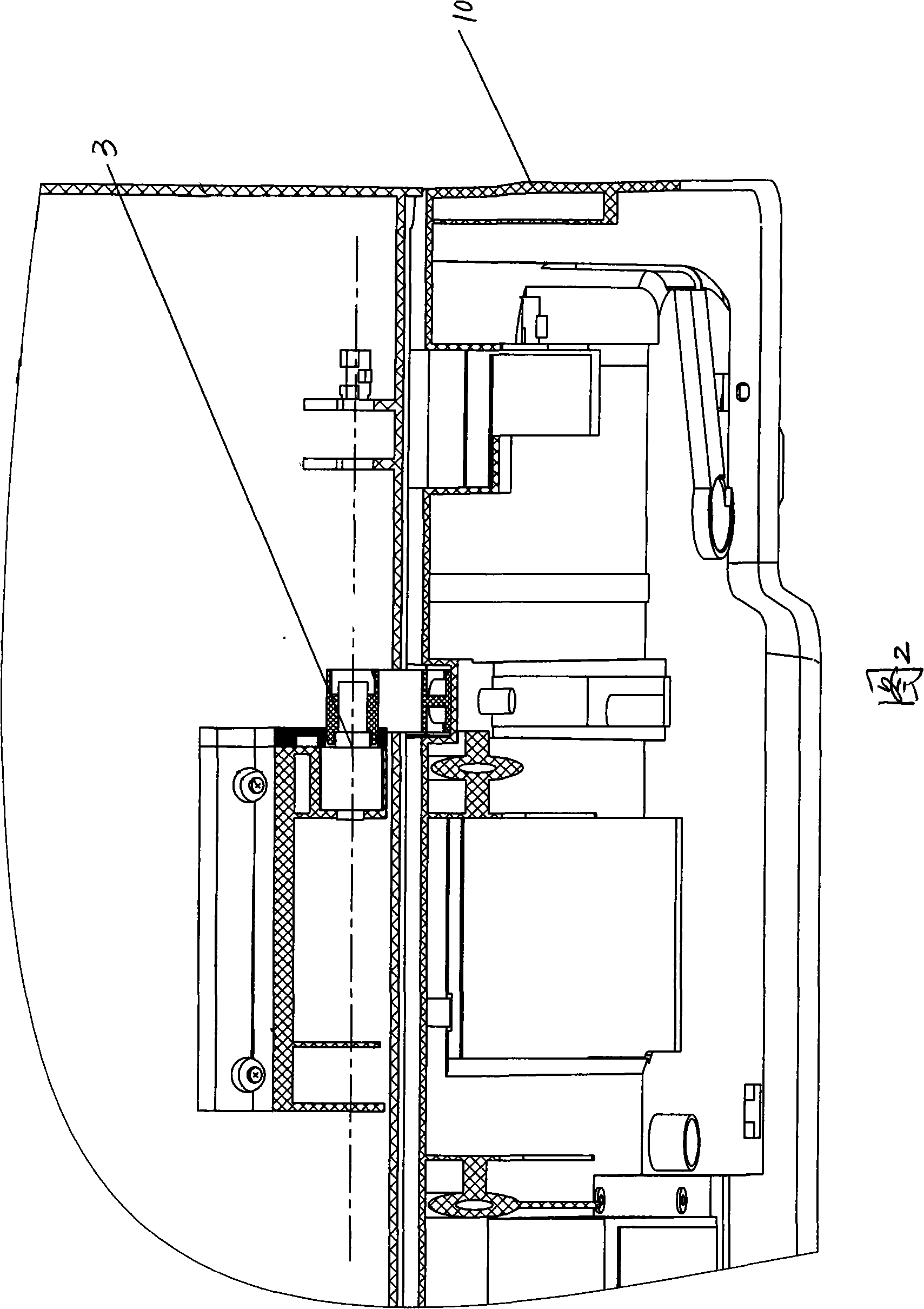

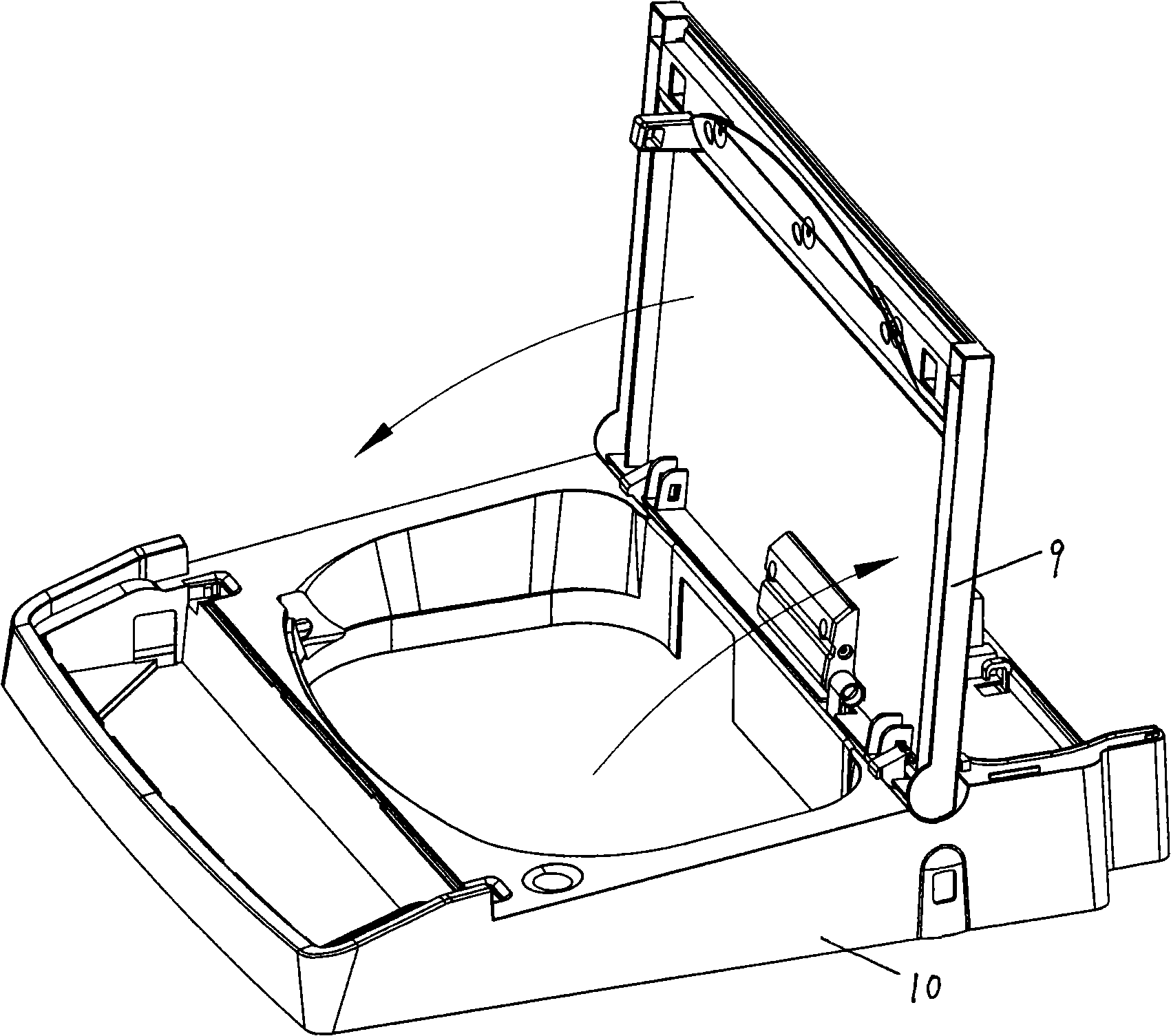

[0015] A damping adjustment rotating shaft mechanism that can be used for the cover plate of a washing machine, including a shaft sleeve 1, the left and right sides of the inner wall of the shaft sleeve 1 have a fin plate 2 with a push-flow effect, and a shaft 3 is installed in the shaft sleeve 1 , the left and right sides of the rotating shaft 3 respectively have a wing plate 5 with an opening 4 in the middle, and a reed 6 is respectively inserted in the opening 4 of each wing plate 5 , and the gap between the rotating shaft 3 and the bushing 1 is filled with Damping liquid or damping paste 7, a sealing gland and a honey seal ring assembly 8 are installed between the rotating shaft 3 and the end of the shaft sleeve 1 to prevent the leakage of the damping liquid or damping paste 7, the fins 2 and the fins 5 are interlaced, and the rotating shaft 3 can rotate in the shaft sleeve 1, and there is a gap between the fin plate 2 and the shaft 3, and between the wing plate 5 and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com