Seed metering and distributing device for precision drill

A kind of seeder, precision technology, applied in the direction of single-grain seeder, seeder parts, etc., can solve the problems of high installation position of seed meter, increase of difference in seed falling time, influence of sowing distance accuracy, etc., and achieve stable performance , The effect of high seed selection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

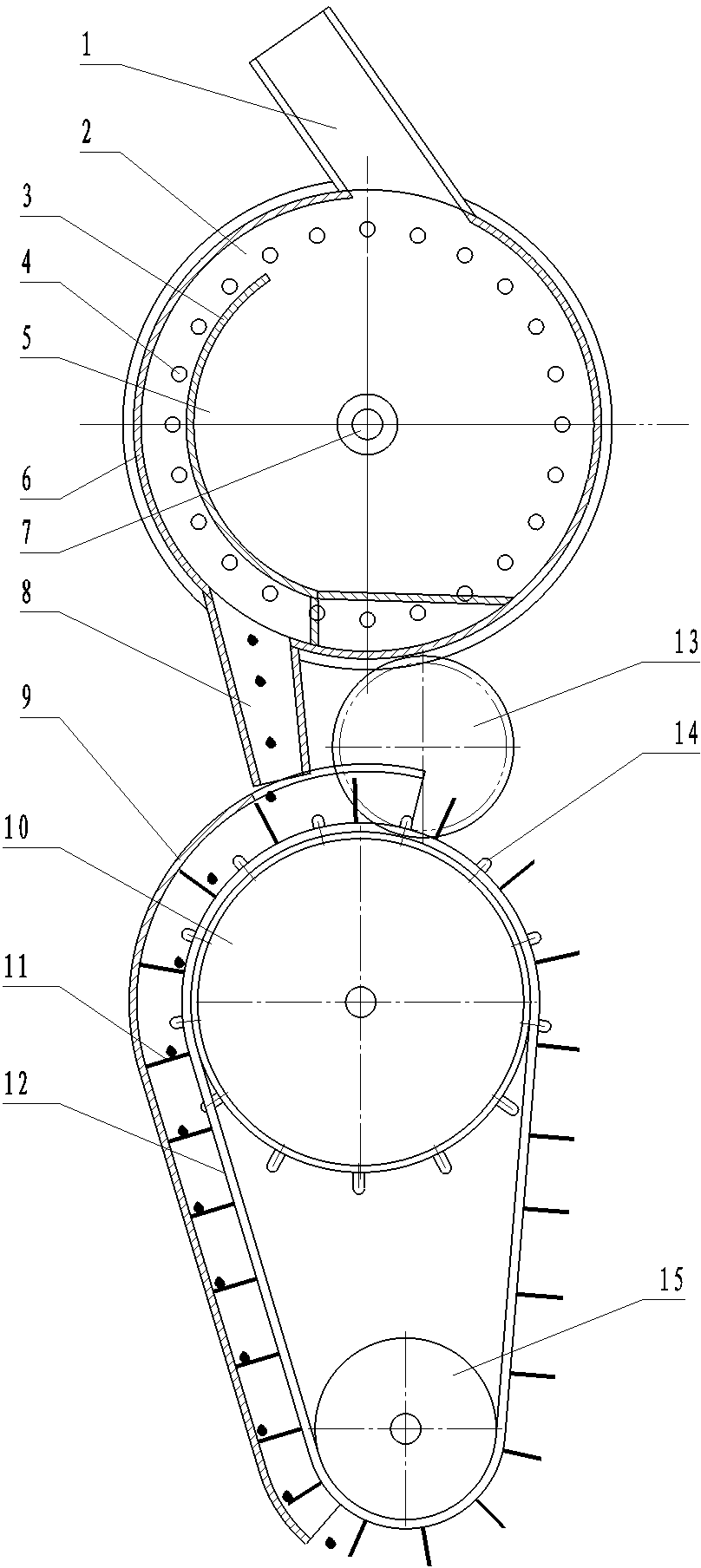

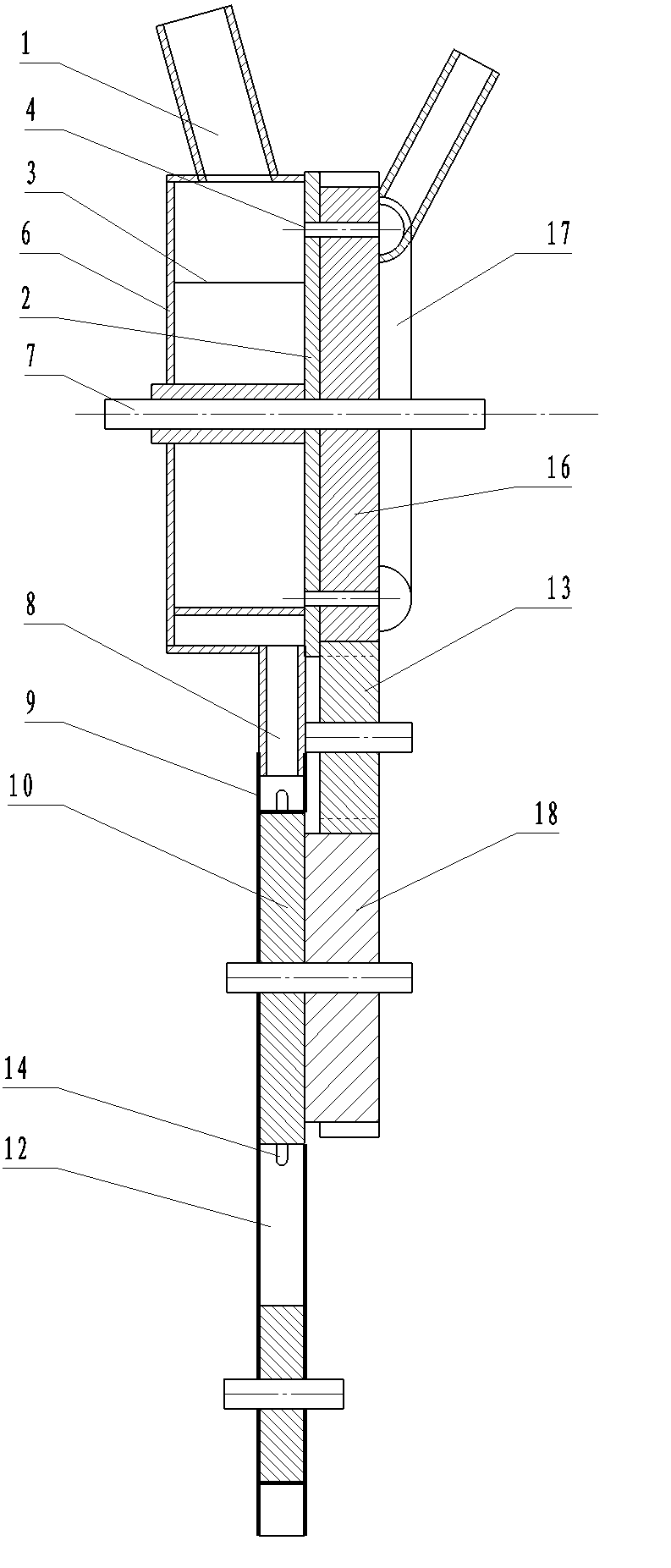

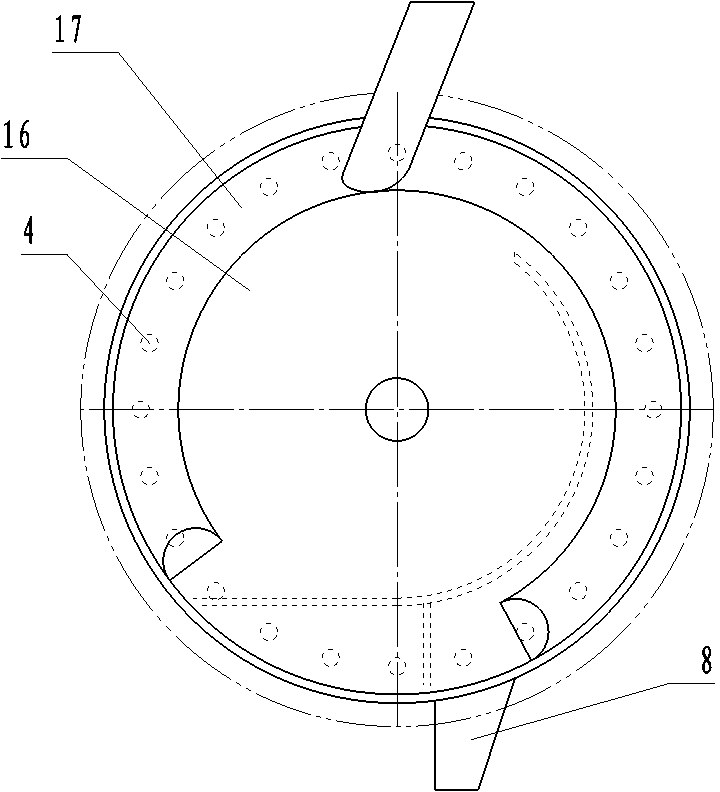

[0024] Embodiment 1: with reference to attached Figure 1 to Figure 6 , is a structural schematic diagram of Embodiment 1 of the present invention, including a seed picking mechanism and a conveying mechanism. The seed picking mechanism includes a seed chamber (5) composed of a moving plate (2) and a fixed plate (6) and a seeding pipe ( 8), a week of the moving disk 2 is provided with a seed suction hole 4, a negative pressure suction pipe 17 is provided on the outer edge of the moving disk along the arc of the seed suction hole 4, a partition 3 is provided in the seed chamber 5, and the seed chamber 5 is divided into a seed-taking area and a seed-injecting area, the seed-discharging pipe (8) is connected to the seed-injecting area, and a drive gear 16 is set on the moving plate (2) of the seed-taking mechanism, and the conveying mechanism is a conveyor belt-type conveying mechanism, Contains driving roller (10), passive roller (15), conveyor belt (12), seed retaining plate (1...

Embodiment 2

[0025] Embodiment 2: with reference to attached Figure 7 , is a schematic structural diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the surface of the driving roller (10) is gear-shaped, and the conveyor belt (12) and the driving roller ( 10) The contact surface is correspondingly toothed.

Embodiment 3

[0026] Embodiment 3: with reference to attached Figure 8 , Figure 9 , is a schematic structural diagram of Embodiment 3 of the present invention. Compared with Embodiment 1, the difference of this embodiment lies in: the driving gear ( 16, 18) are replaced by chain gears 19, 21, and the chain gears 19, 21 are connected by a transmission chain 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com