Pneumatic combined rice seed metering device

A kind of seeding device and rice technology, applied in the direction of seeding machine parts, etc., can solve the problems that affect the precision and efficiency of seeding, the seedling raising method is only suitable for manual transplanting, and the cleaning is inconvenient, so as to achieve stable work, high work efficiency, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

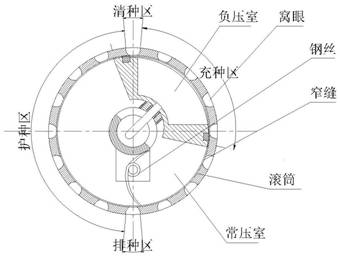

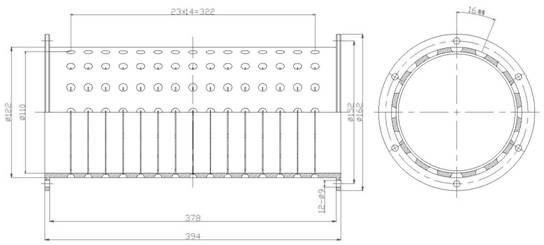

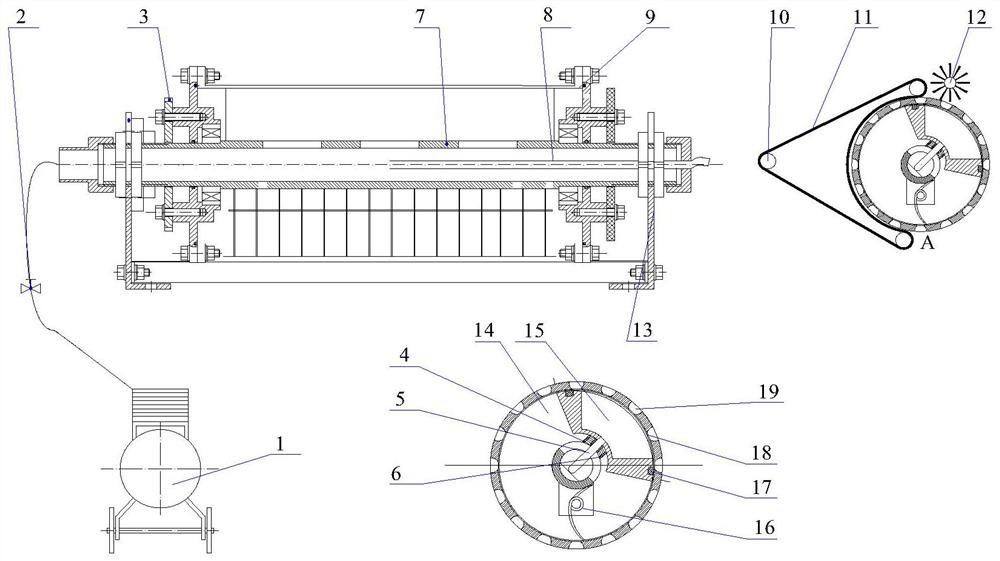

[0013] The overall structure of the metering device designed by the present invention is as follows: figure 1 shown. The specific installation process is as follows: ①The bullet steel wire is pre-installed on the hollow shaft, the spring guide column is pressed against the gasket and installed on the inside of the hollow shaft, and the spring guide column is installed in turn with the linear bearing and the spring of the negative pressure chamber; ②The vacuum pump passes through the air pipe and the negative pressure chamber The overall negative pressure chamber is assembled with the hollow shaft through linear bearings; ③The above two steps are installed inside the drum, the bullet steel wire and the spring of the negative pressure chamber are in a compressed state, and the bearing and the Install the end cover of the drum, and install the gear on the left side to drive the drum to rotate; ④The hollow shaft is fixed on the brackets on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com