Novel feed feeding and packaging equipment

A technology for packaging equipment and feed, applied in the field of new feed feeding and packaging equipment, can solve the problems of reducing economic benefits, consuming resources, and unable to quantitatively pack materials, and achieving the effect of ensuring economic benefits and reducing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

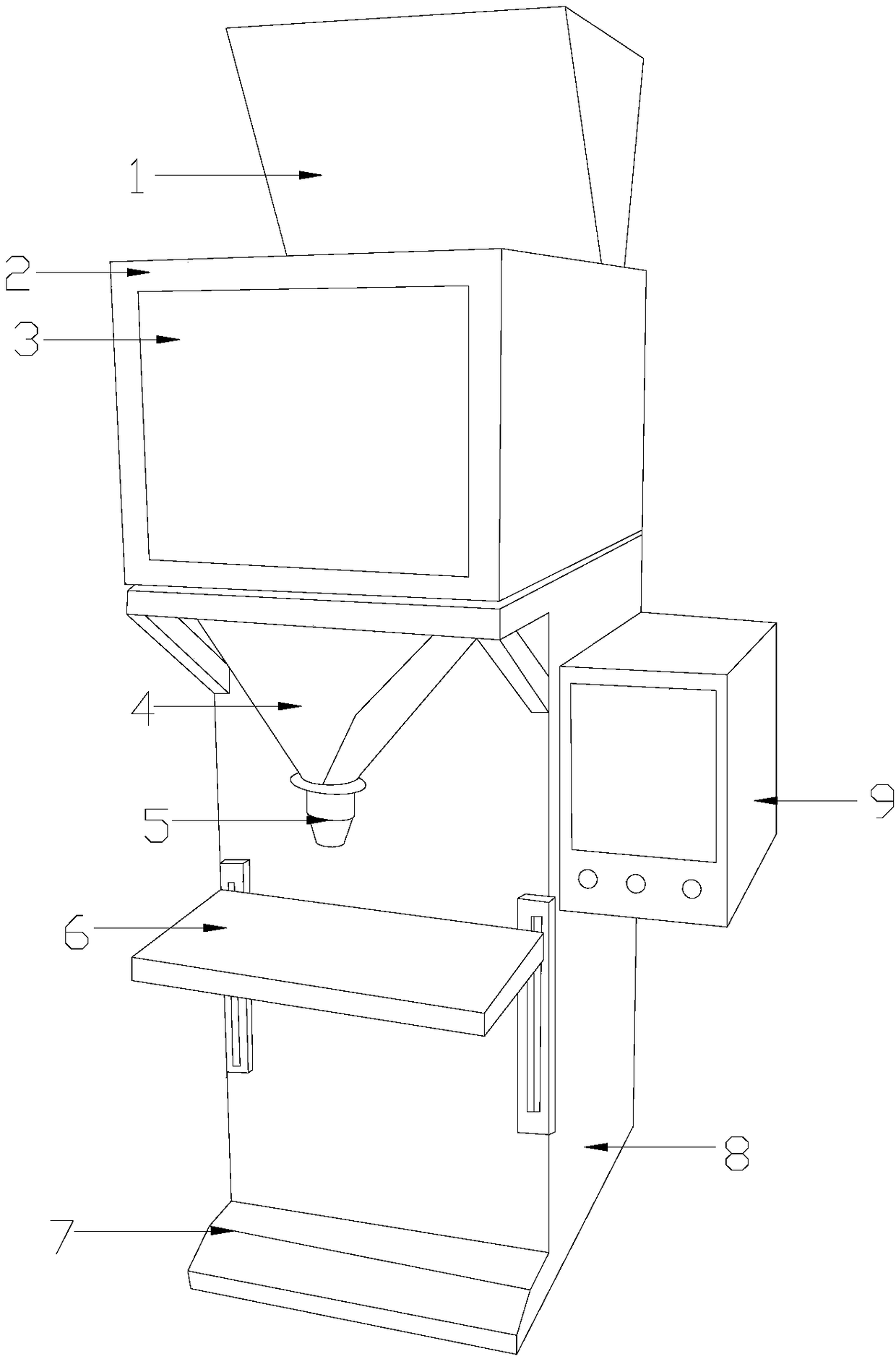

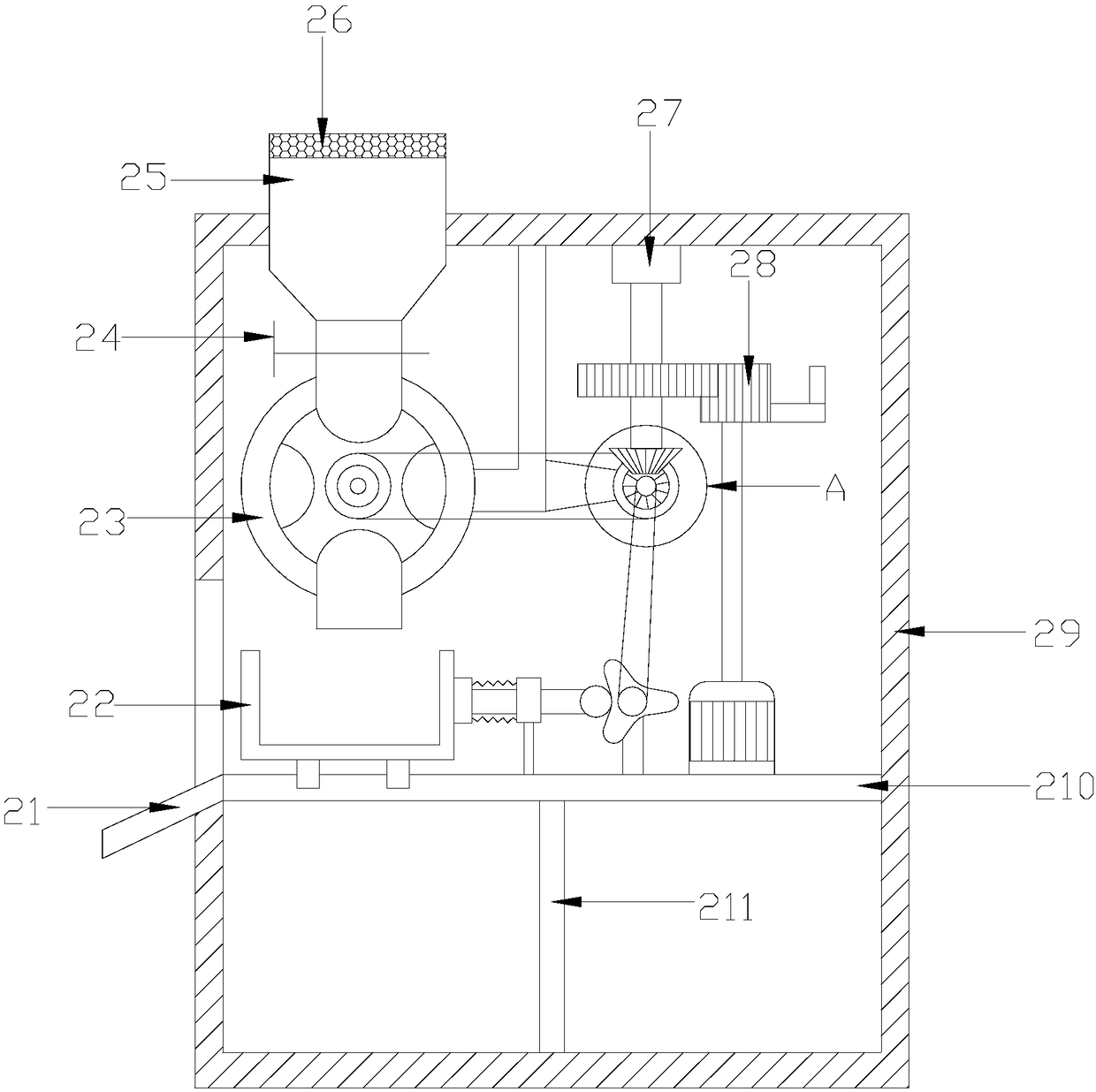

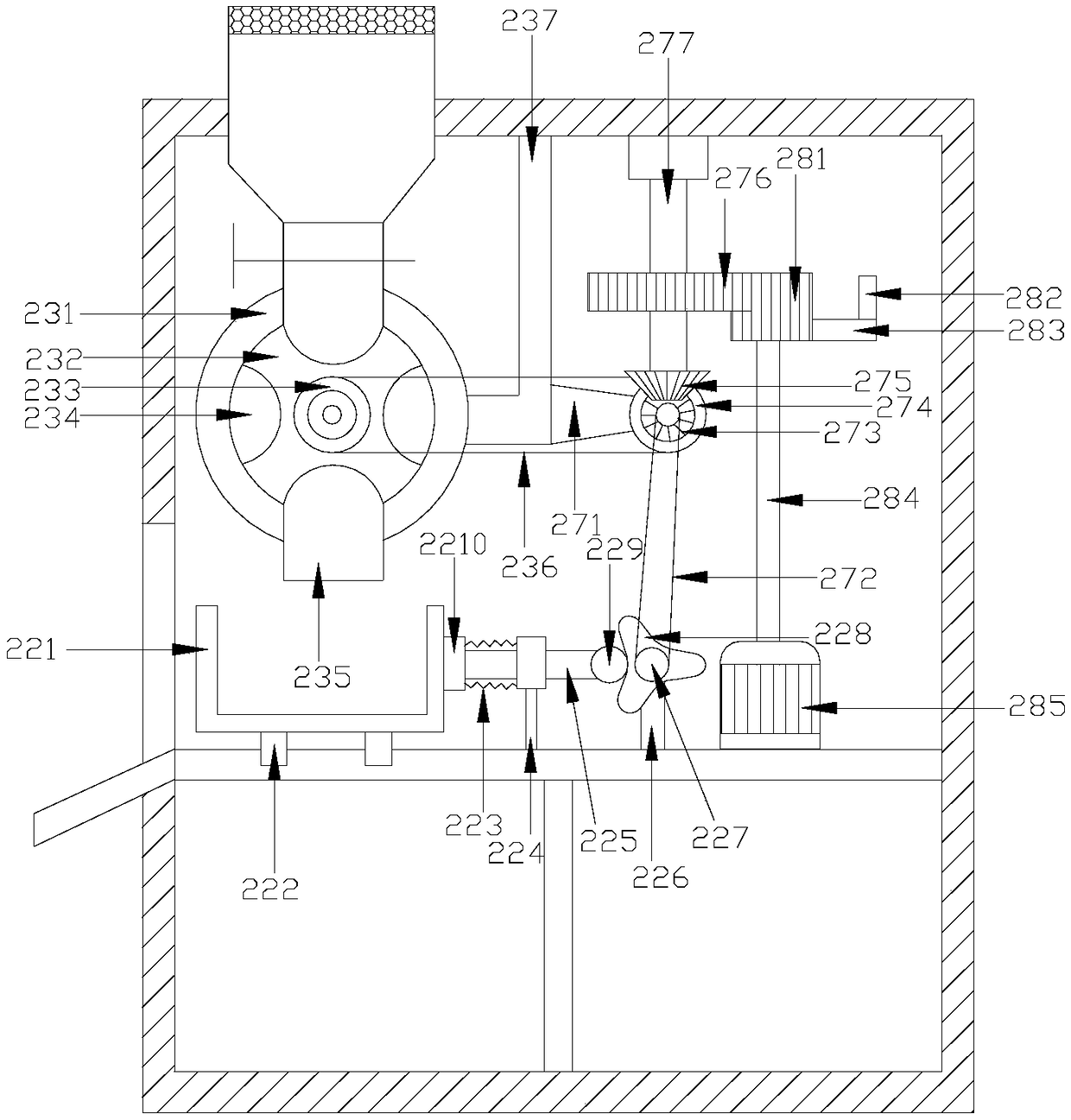

[0021] Such as Figure 1-Figure 5As shown, the present invention provides a new type of feed feeding and packaging equipment, its structure includes a hopper 1, an automatic quantitative packaging mechanism 2, an observation window 3, a hopper 4, a discharge pipeline 5, a lifting work platform 6, a fixed base 7, a working Frame 8, control cabinet 9, the bottom of the working frame 8 is fixedly welded on the upper end of the fixed base 7 and the two are integrally formed structures, the bottom of the automatic quantitative packaging mechanism 2 is fixedly welded on the top of the working frame 8 and the two The two are interconnected, the bottom of the hopper 1 is fixedly welded to the rear side of the top of the automatic quantitative packaging mechanism 2, and the front end of the automatic quantitative packaging mechanism 2 is fixedly provided with a movable device observation window 3, and the two are integrally formed structures. The discharge hopper 4 is fixedly welded on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com