Grinding internal cooling system capable of automatically calibrating liquid supply position

An automatic calibration and grinding technology, applied in the field of grinding, can solve problems such as splashing of grinding fluid, and achieve the effects of improving use efficiency, being beneficial to environmental protection and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

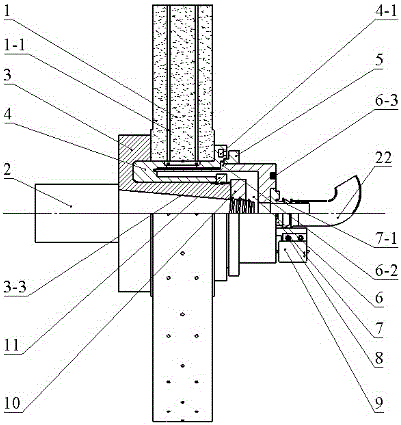

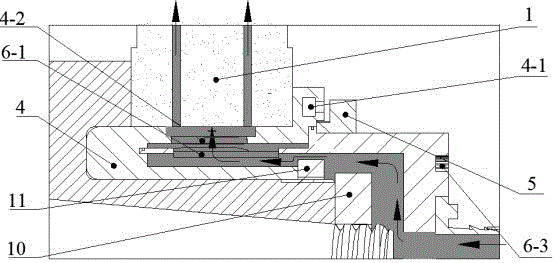

[0035] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

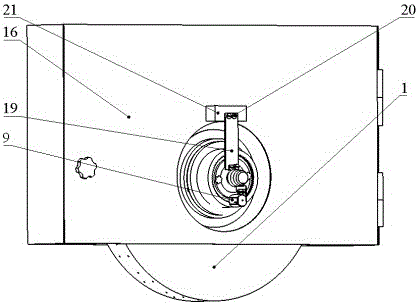

[0036] The invention relates to an internal cooling system for grinding processing capable of automatically calibrating the liquid supply position, mainly comprising a grinding wheel device and an automatic calibration mechanism for the liquid supply position. The grinding wheel device includes an internal cooling grinding wheel 1, a liquid guide grid 4, a flange 3 and a nut 11; the liquid supply position automatic calibration mechanism includes an adjusting sleeve 6, a joint 7, a motor 9 and a gear 12. The grinding fluid enters the adjustment sleeve 6 from the liquid inlet 7-4 on the joint 7, and then flows through the rectangular opening 6-1 on the adjustment sleeve 6, the oval hole 4-2 on the liquid guide grid 4, the inner The radial small holes 1-1 on the cold grinding wheel 1 finally flow into the grinding center area. In this process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com