Coating filtering device with alarm function

A filter device and coating technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as increasing labor and time, affecting normal production, and poor coating flow, so as to reduce cleaning times and alleviate stirring problems , Enhance the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings.

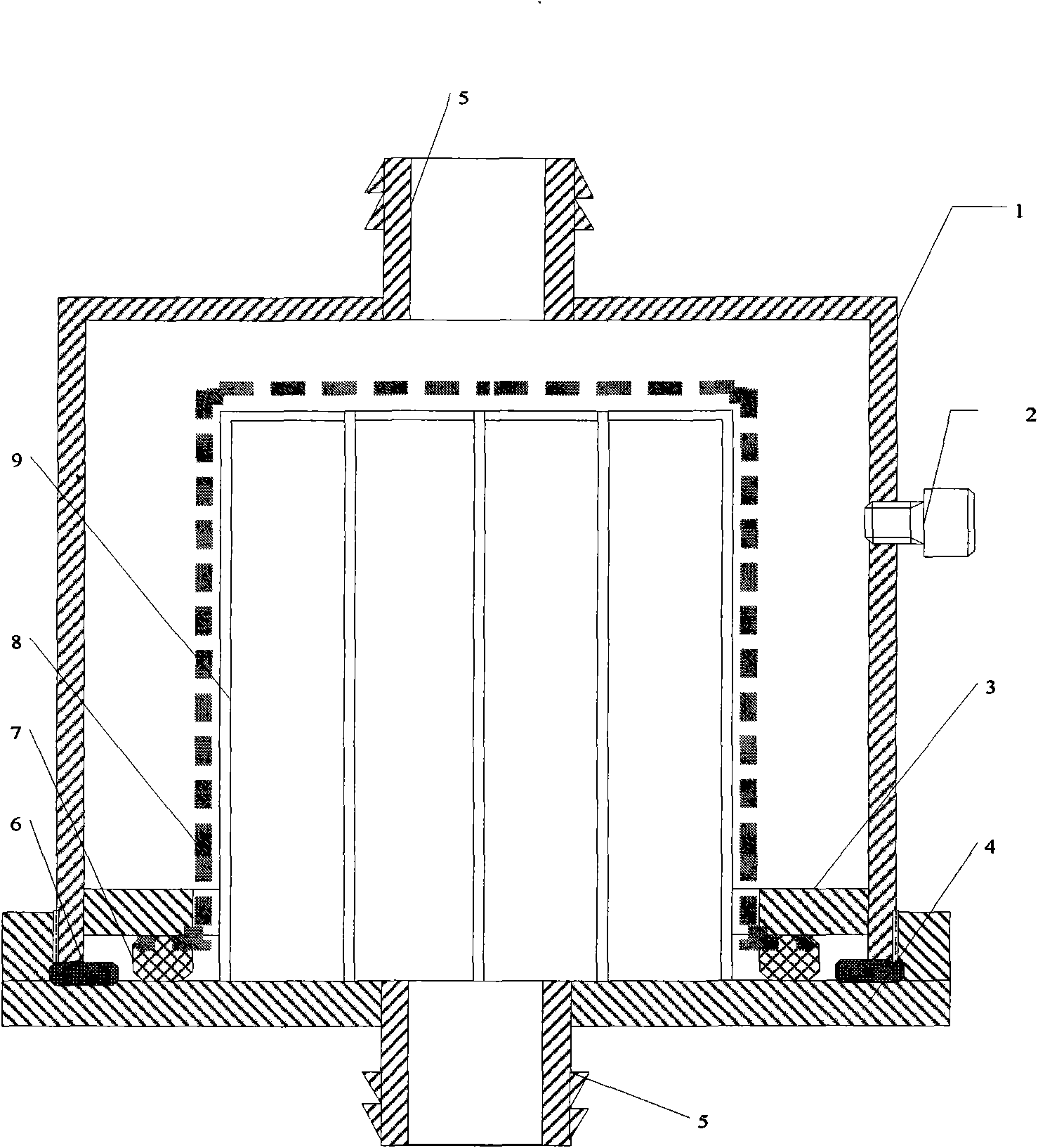

[0015] As can be seen from the accompanying drawings, the paint filtering device with alarm function of the present invention is composed of a housing 1, a pressure sensor 2, an inner ring of the housing 3, an end cover 4, a short pipe 5, a sealing gasket 6, an annular elastic body 7, a filter screen 8, Filter screen support 9 and the external alarm that is connected with pressure sensor 2 form.

[0016] The shape of the housing 1 of the filtering device is a hollow cylinder, and a short pipe 5 connected to the external paint pipeline is welded at the center of the upper end of the housing 1, and the lower end of the housing 1 is an open end; The bottom is welded with the housing inner ring 3. The side of the cylindrical shell 1 is provided with an opening, and the opening is used for installing the pressure sensor 2 . The opening end of the pressure sensor 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com