Elastic strip post-breakage splashing preventive structure for fastener system

An anti-fracture and elastic strip technology, which is applied to fixed rails, roads, buildings, etc., can solve the problems of unconstrained parts splashing out, hitting vehicle equipment pedestrians, and vehicle damage, etc., and achieves simple structure, increased insulation performance, and installation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

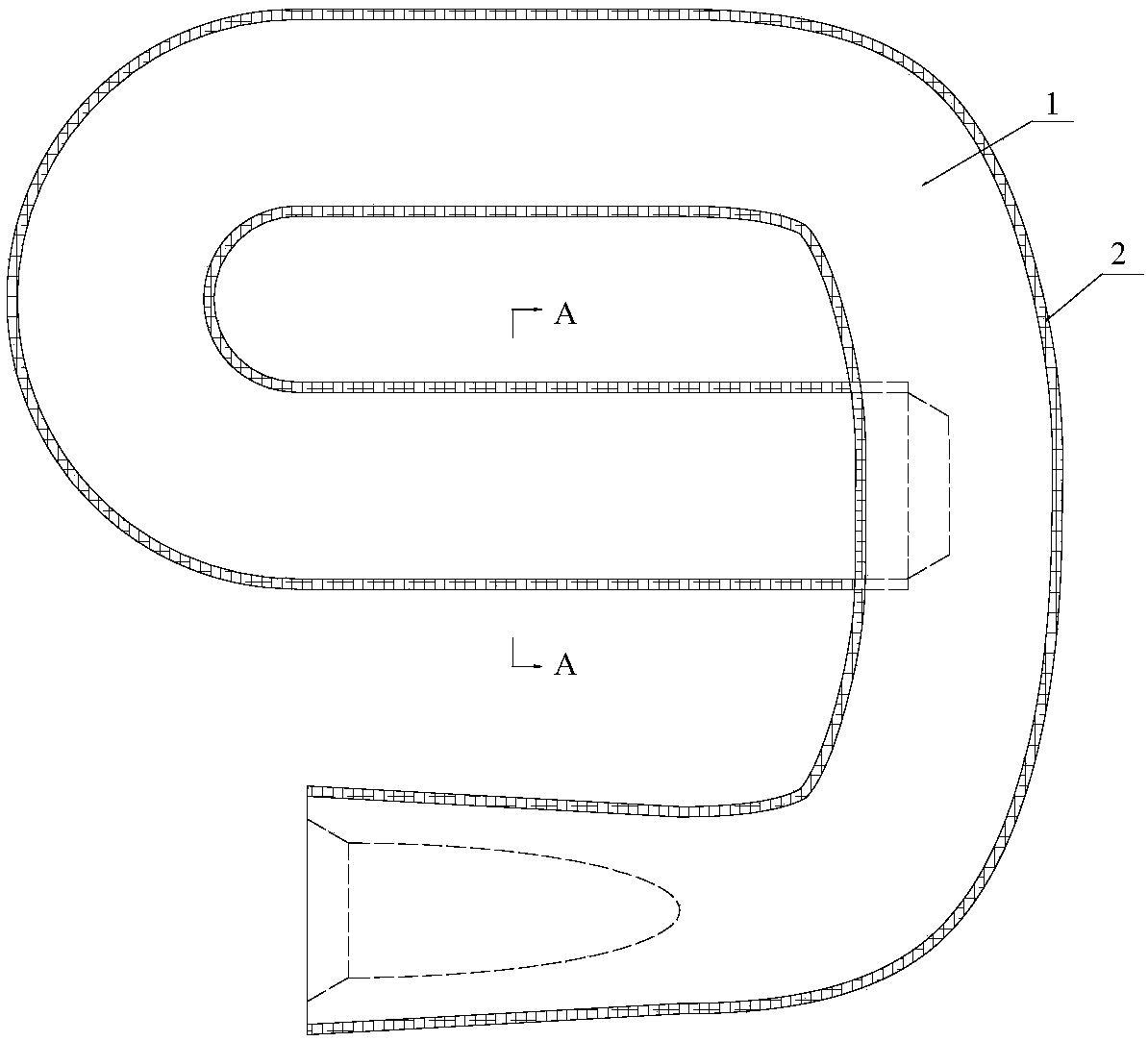

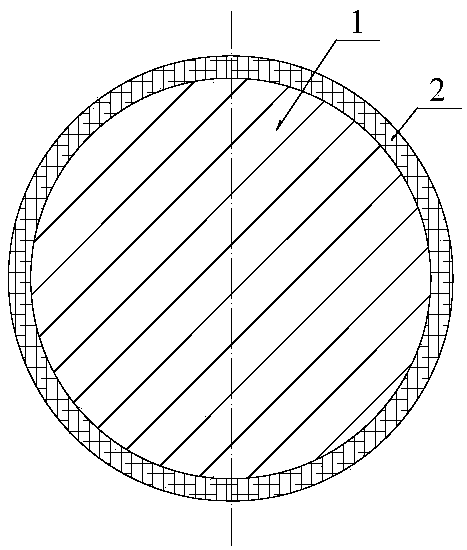

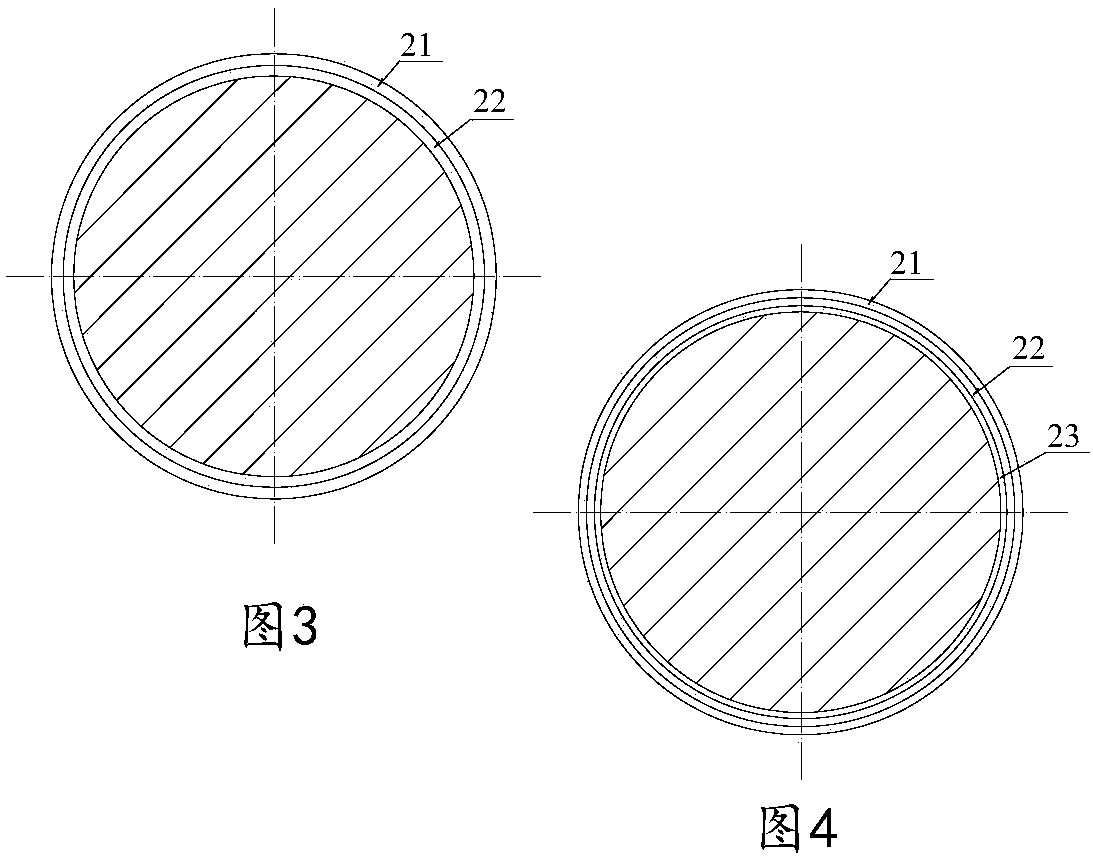

[0017] refer to figure 1 , Figure 5 , the anti-splash structure of the clip system of the fastener system of the present invention includes a clip body 1, the annular section of the clip body 1 is covered with a flexible protective sleeve 2, and the flexible protective sleeve 2 forms a tight fit with the clip body 1 connect. Even if the clip body 1 breaks, the flexible protective cover 2 wrapped on its outer surface will not break, and the broken clip body 1 is constrained by the flexible protective cover 2, effectively solving the problem of splashing or popping up after the clip body breaks . Since the flexible protective sleeve 2 effectively isolates the rail from the spring bar body 1, the insulation performance of the fastener system can be increased. The invention has the characteristics of simple structure, good splashing effect of the bulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com