Yarn guide device having original-point positioning function

A yarn guide device and origin positioning technology, applied in textiles and papermaking, can solve problems such as inconsistent running directions of timing belts and linear guide rails, high manual maintenance costs, uncontrolled transmission speed, etc., to achieve high quality and stability Automatic winding, high cost of manual maintenance and repair, and the effect of reducing the probability of yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

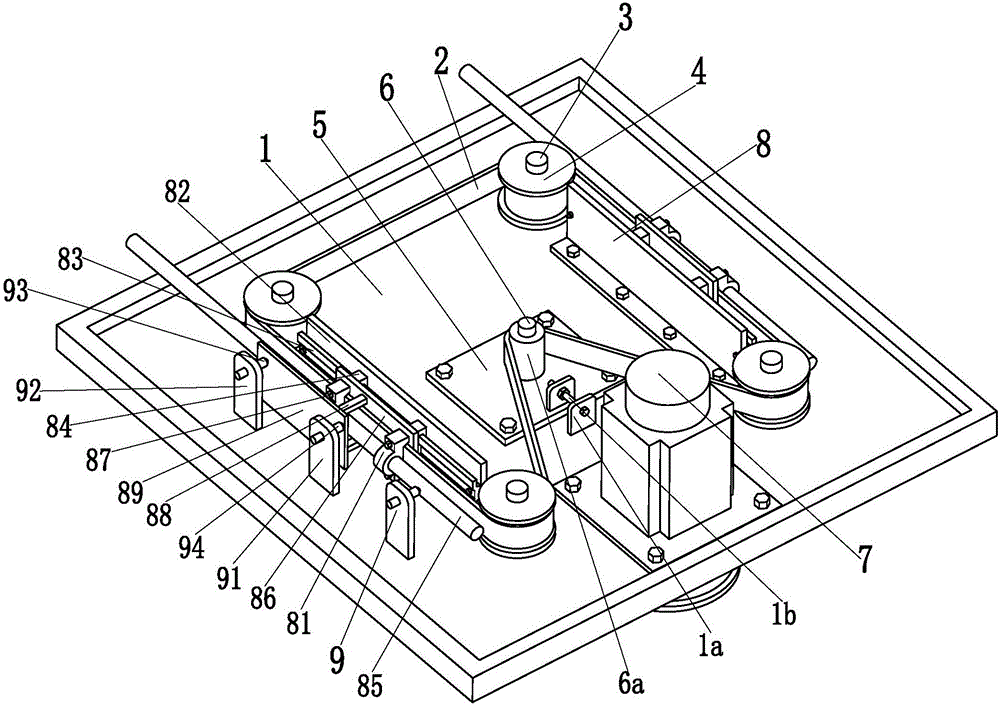

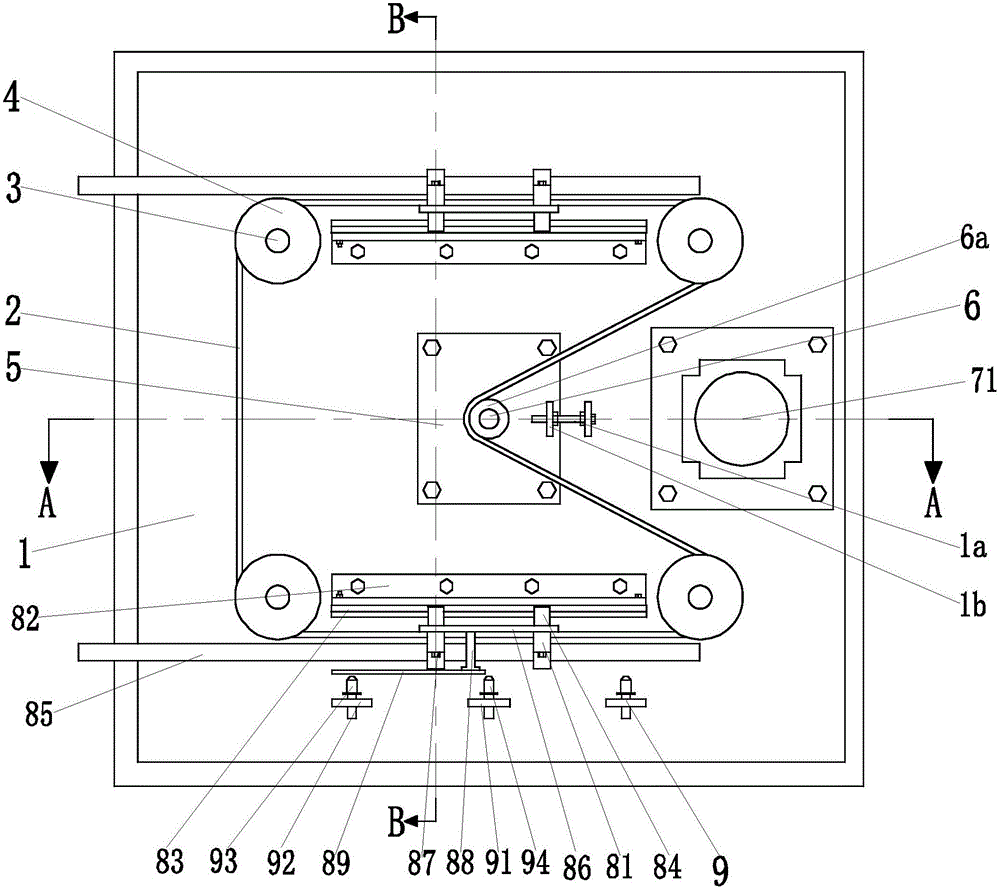

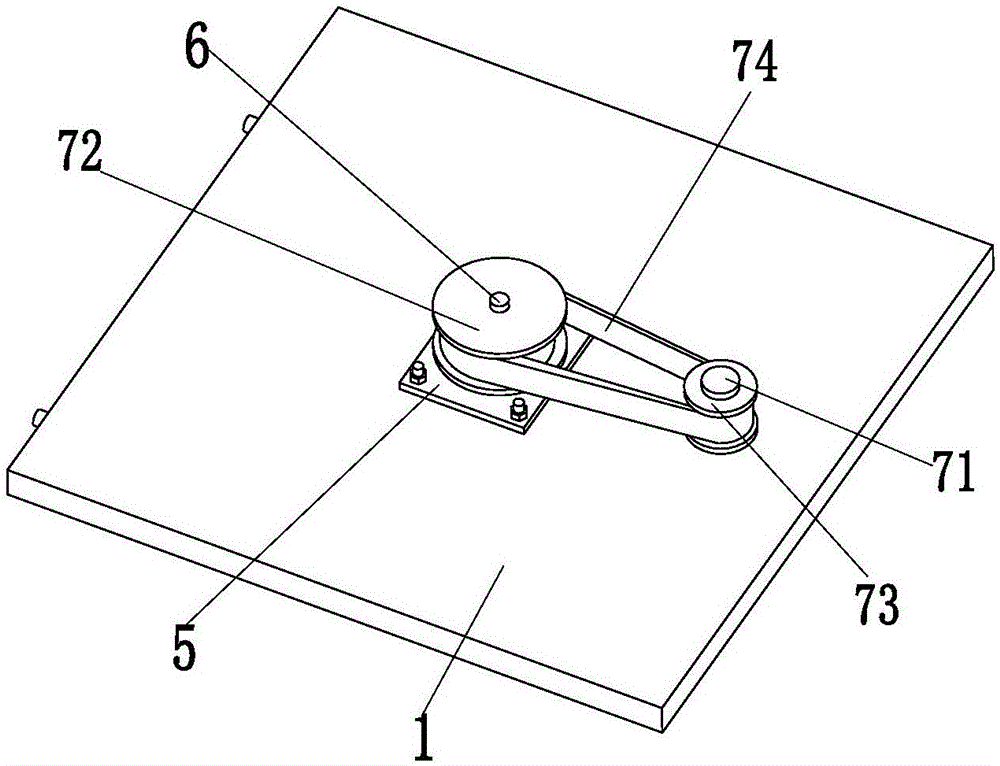

[0023] Such as Figure 1 to Figure 6 As shown, a yarn guide device with origin positioning function includes a base plate 1 and a main timing belt 2. The upper end surface of the base plate 1 is symmetrically welded with four fixed shafts 3, and the four fixed shafts 3 are respectively installed through bearings. There are four transmission pulleys 4, and the four transmission pulleys 4 can stably rotate on four fixed shafts 3 through bearings; the middle part of the base plate 1 is provided with a transmission hole, and the upper and lower ends of the middle part of the base plate 1 are symmetrically installed with two bolts. Mounting plate 5, the drive shaft 6 is installed in the middle of the two mounting plates 5 through bearings, and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com