Shot blasting structure

A technology of steel shot and box body is applied in the field of shot blasting device, which can solve the problems of difficult removal and reduce the effect of removing rust, and achieve the effects of preventing pollution, improving the effect of removing rust, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

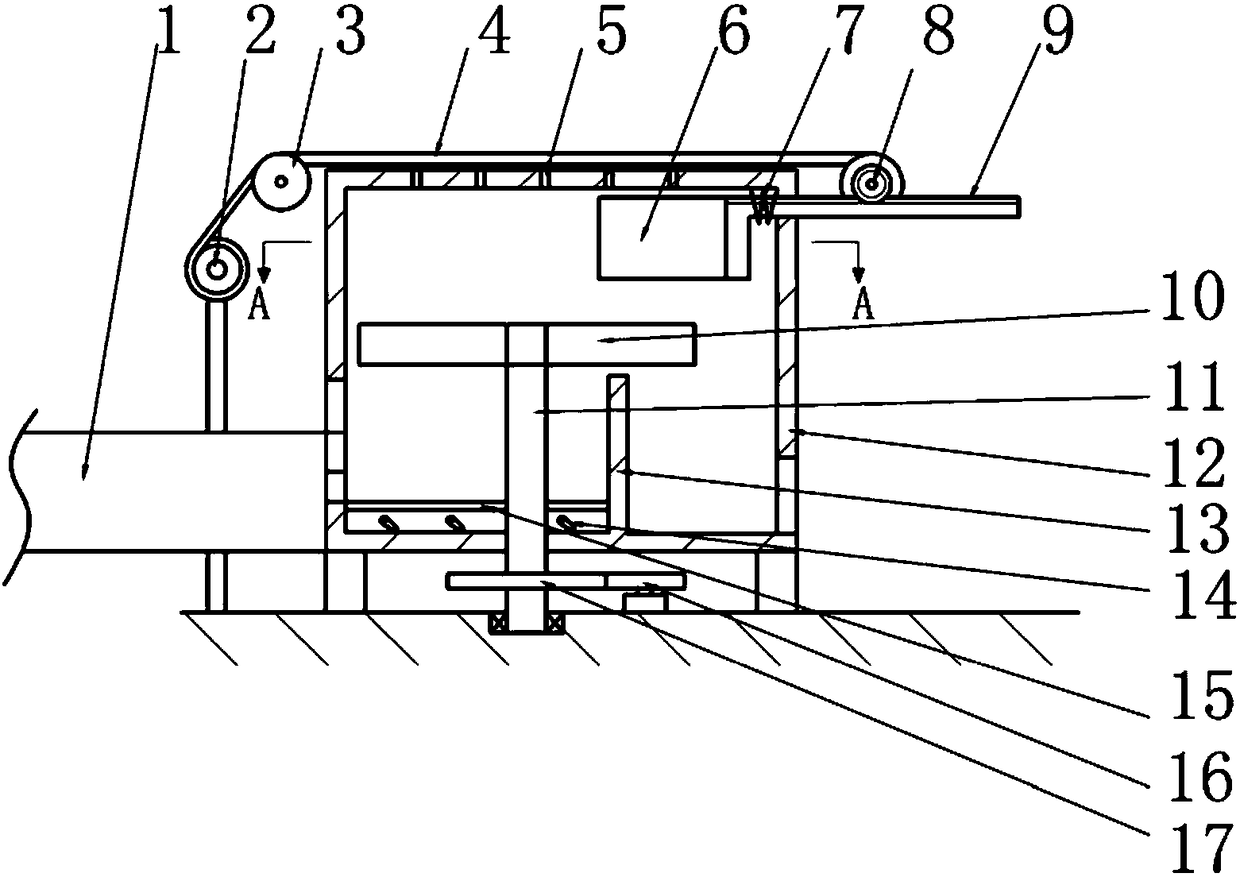

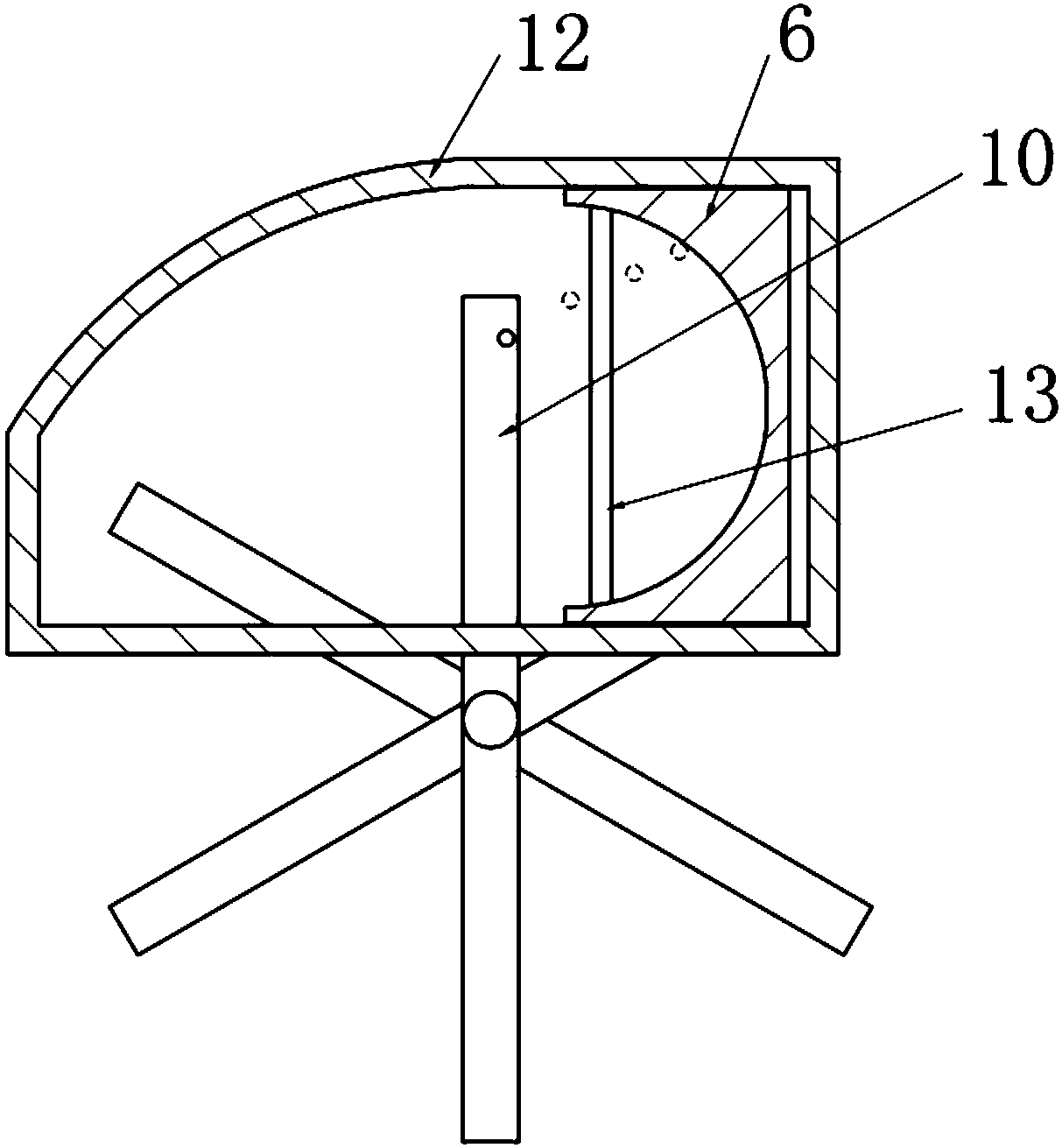

[0020] Embodiment: the shot blasting structure in this scheme, as figure 1 with figure 2 As shown, it includes a screening device, a blade shot separating device and a winding device. The screening device includes a casing 12 and a vibrating mechanism 14. The bottom of the casing 12 is fixedly connected with a box body 12. The clapboard 13. Vibration mechanism 14 comprises vibrating plate 15, and vibrating plate 15 is vertically slidably connected in the screening cavity, and vibrating plate 15 is driven to vibrate up and down by eccentric wheel mechanism, and eccentric wheel mechanism belongs to prior art, does not repeat them here.

[0021] The blade shot-dividing device includes a rotating shaft 11 positioned outside the casing 12 , six blades 10 are fixedly connected to the peripheral side of the rotating shaft 11 , and the blades 10 are positioned above the dividing plate 13 . The blade 10 is inclined along the rotation direction of the rotating shaft 11, so that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com