Finishing Forming Method and Finishing Punch of Three-Ballway Constant Velocity Universal Joint Cylindrical Shell

A technology of constant velocity universal joints and cylindrical shells, which is applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as three-channel drum shape errors, high assembly difficulty, abnormal noise of drive shafts, etc., and is easy to achieve Assembling, shortening of production cycle, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

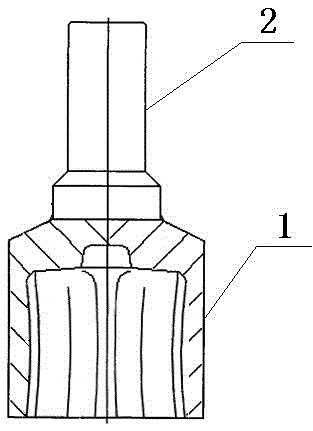

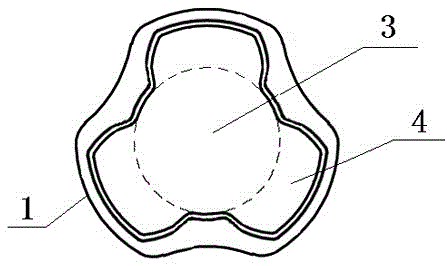

[0025] Example: see figure 1 , figure 2 As shown, a three-ball constant velocity universal joint cylindrical shell precision forging, including a cylindrical shell shell 1 and a handle 2 provided at the lower end of the shell, the cylindrical shell shell 1 is provided with a hollow cavity , the middle hole cavity is composed of a central circular cavity 3 and three ball channel cavities 4 evenly distributed outside the central circular cavity, and the inner wall of the cylindrical shell shell 1 is a convex arc surface, that is, the The central circular cavity 3 and the three ball channel cavities 4 have a structure with a large inner diameter at the ends of the two cavities and a smaller inner diameter at the middle.

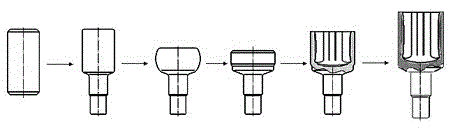

[0026] see image 3 , Figure 4 and Figure 5 As shown, a method for finishing and forming a cylindrical shell of a three-ball constant velocity universal joint, including warm forging and cold finishing plastic forming steps, the warm forging forming proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com