Slag removal electric welding machine

An electric welding machine and slag cleaning technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low production efficiency and dust pollution of the workshop environment, and achieve the effect of high production efficiency and protection of the production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

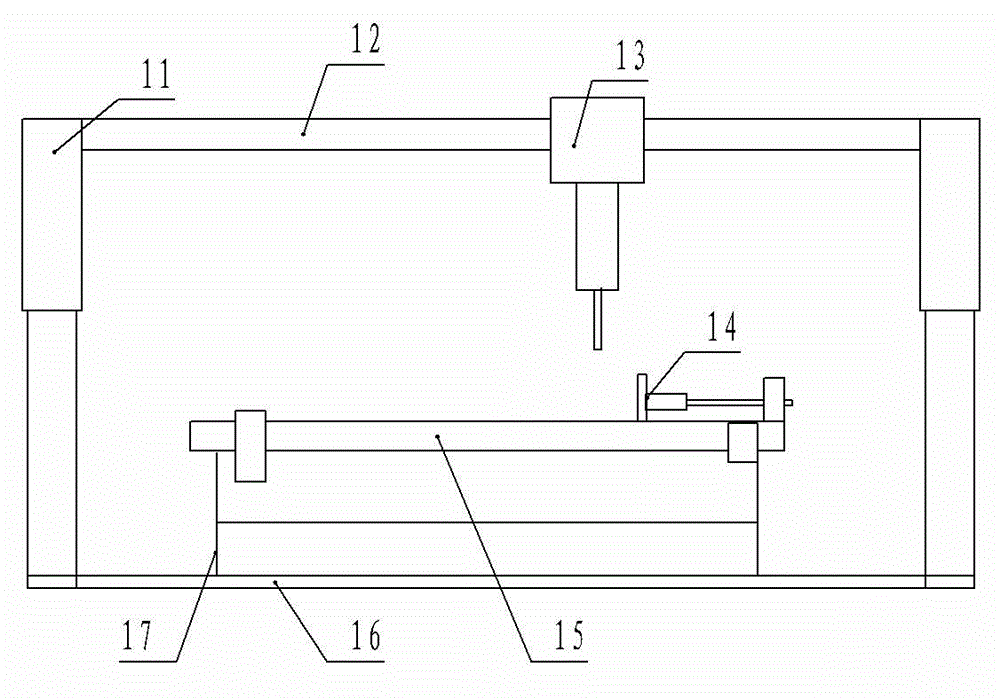

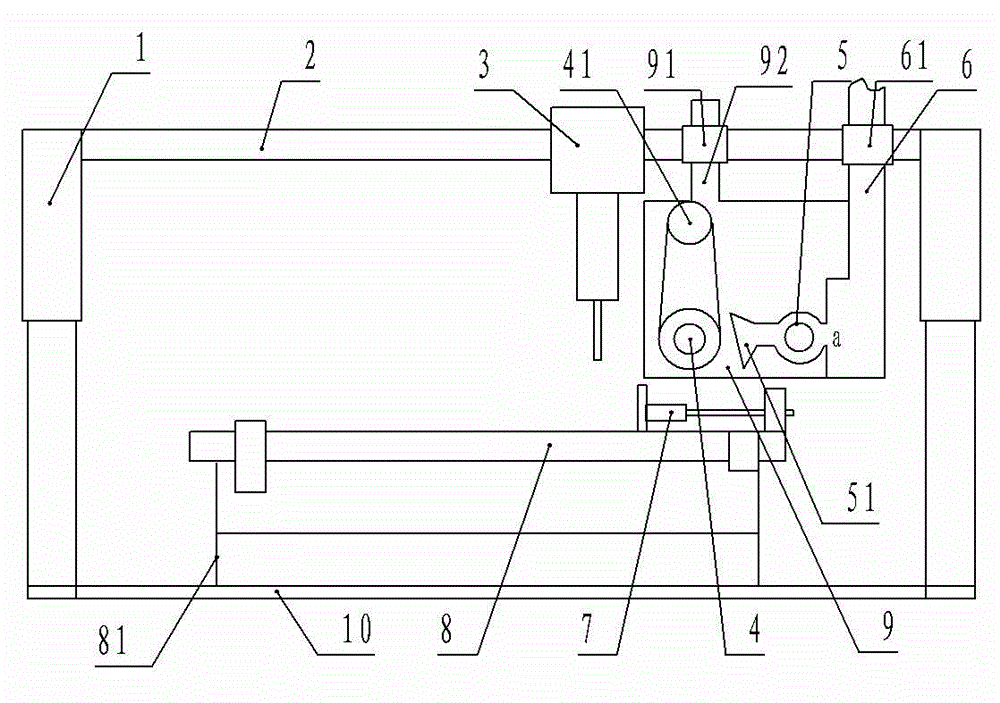

[0012] Below in conjunction with accompanying drawing embodiment, the present invention is described in further detail:

[0013] figure 2 The shown slag cleaning electric welding machine includes a guide rail beam 2 fixedly connected between the upper parts of two vertical frames 1, a welding torch 3 slidingly connected with the guide rail beam 2, and fixedly connected to the lower part of the two frames 1. A chute 10 connected between them; a mounting plate 9 is provided on one side of the welding torch 3, and the mounting plate 9 has an upward protrusion 92, which is slidably connected to the rail beam 2 through the first connecting piece 91, The grinding wheel 4 driven by the motor 41 and the suction nozzle 51 for sucking welding slag through the suction fan 5 are installed on the mounting plate 9 in sequence. It is connected with the grinding wheel 4 through the belt; the air outlet of the suction fan 5 is communicated with the air duct 6, the air duct 6 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com