Barrel plating automatic washing device

An automatic cleaning and barrel plating technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of unreasonable cleaning water consumption, labor-intensive workers, and only manual operation. Achieve the effect of reducing unreasonable water use, improving industry competitiveness, and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

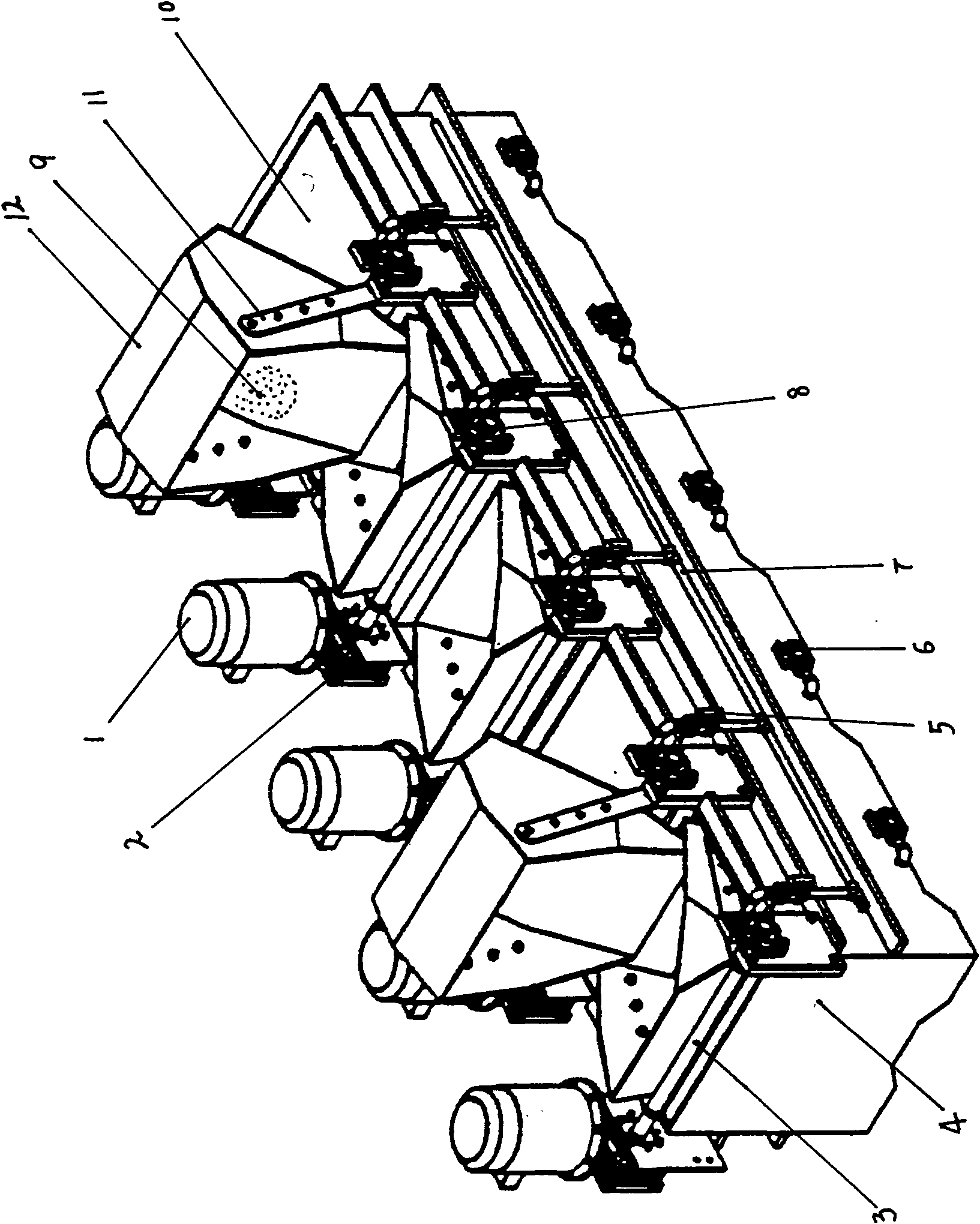

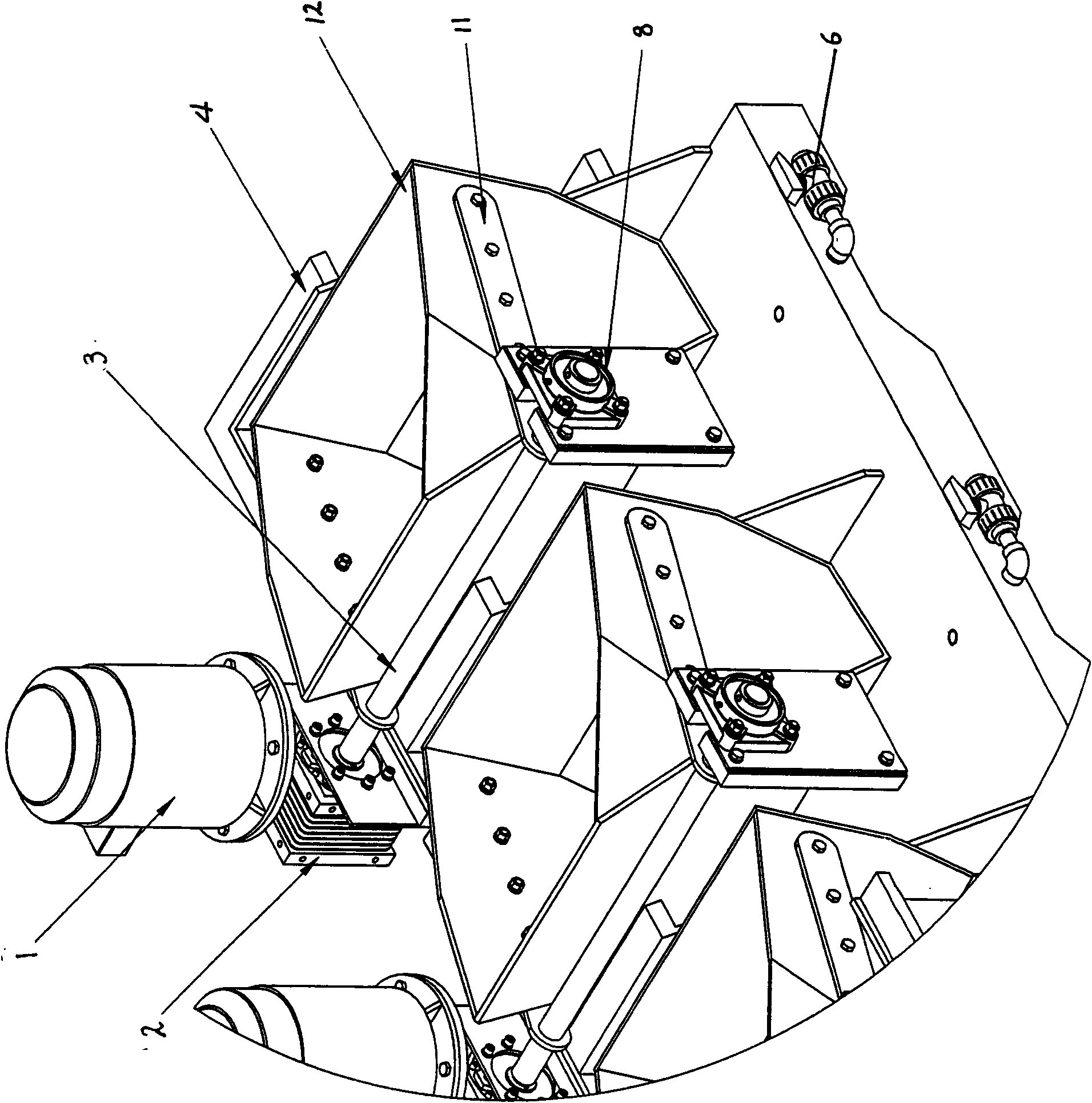

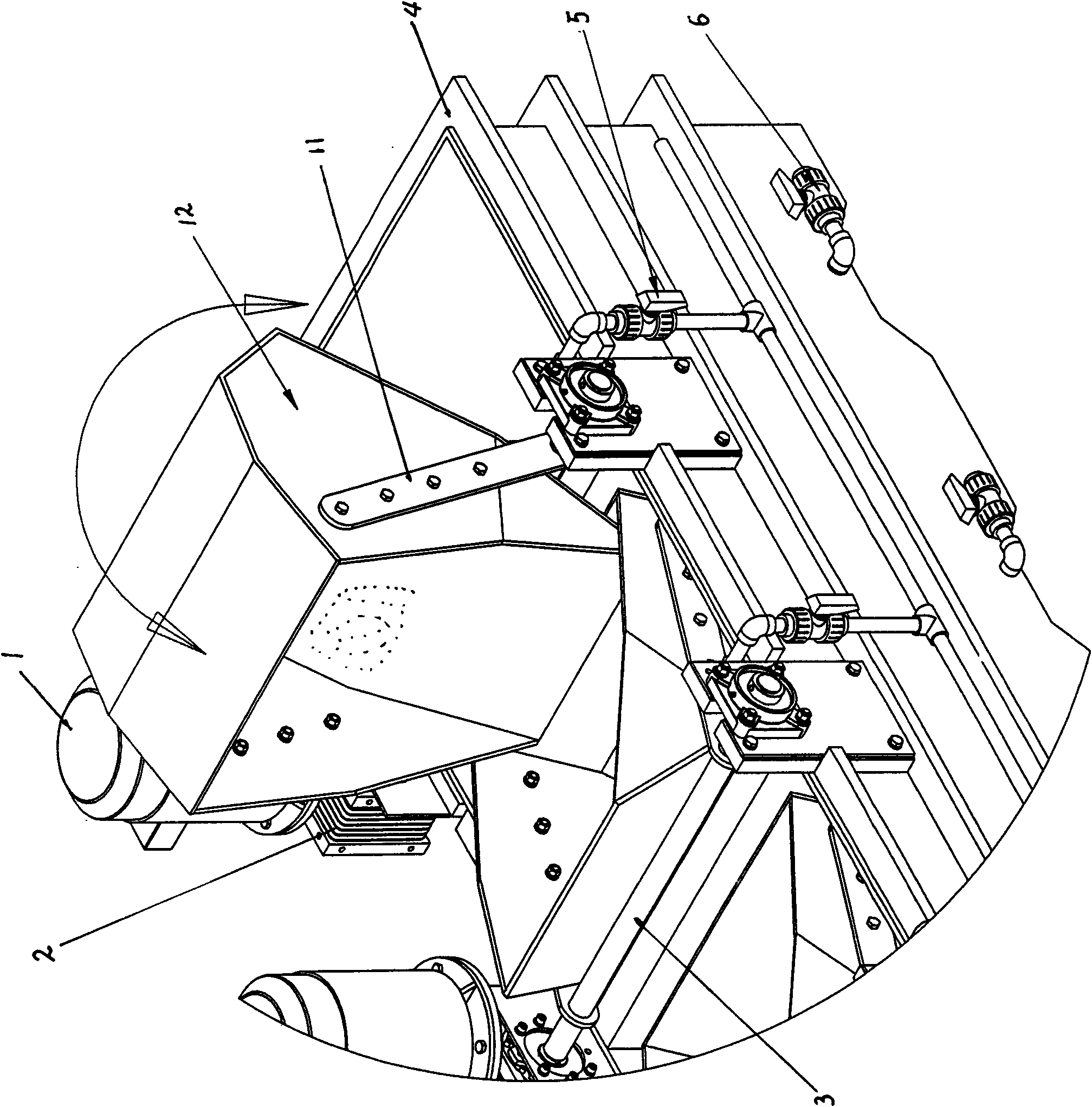

[0020] With reference to the accompanying drawings, its structure is described in detail.

[0021] exist Figure 1~3 Among them, the tank body 4 of this cleaning device is a conjoined tank body, and several cleaning tanks 10 are arranged in the tank body, and the cleaning liquid in each cleaning tank is not connected to each other, and a hopper 12 and a turning device are arranged on the tank body, and the turning device includes a motor , a gearbox, a rotating shaft and a swing arm, the hopper 12 is fixed on the rotating shaft 3 through the swing arms 11 installed on both sides of the hopper, a motor 1 and a gearbox 2 are arranged on the frame of the tank body 4 on one side, and the other side The frame is provided with a bearing seat 8, the motor shaft is connected with the gearbox, and one end of the rotating shaft is installed on the bearing seat, and through the power transmission of the motor rotation and the gearbox, the rotating shaft drives the hopper to rotate (turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com