Improved structure for vibrating screen cover plate

A vibrating screen and cover plate technology, which is applied in the direction of engine sealing, filter screen, engine components, etc., can solve the problems of screen blockage, affecting sealing effect, affecting production efficiency and production environment, etc.

Active Publication Date: 2014-07-23

JIAXING BOHONG NOVEL BUILDING MATERIALS

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, during the working process of the vibrating screen, sometimes the screen is blocked and needs to be cleaned manually. Because it is fastened by bolts, sometimes it is necessary to remove the bolts to see if the screen is blocked. Working conditions, and if the cover plate is often disassembled, it will affect its sealing effect, which will greatly affect the production efficiency and production environment for some powder vibrating screens

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

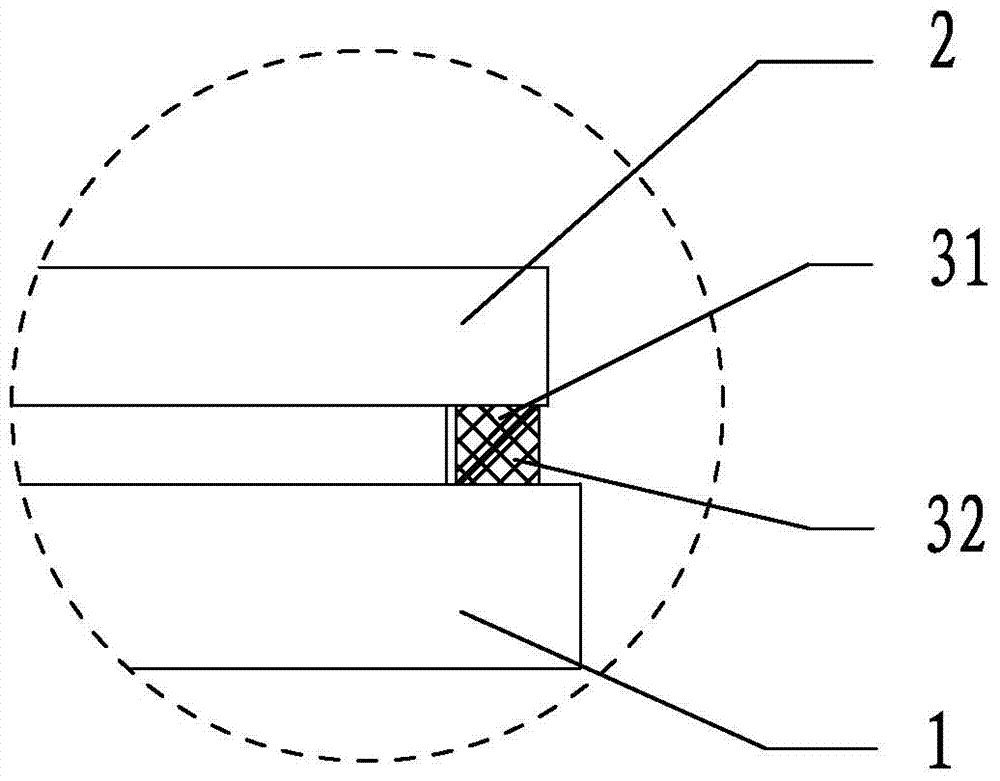

[0018] The two kinds of sealing strips in Example 1 and Example 2 can well achieve the sealing effect between the cover plate body and the vibrating screen body, especially the cover plate body is a movable structure that often needs to be opened and merged. The sealing performance will seriously affect the production efficiency and production environment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

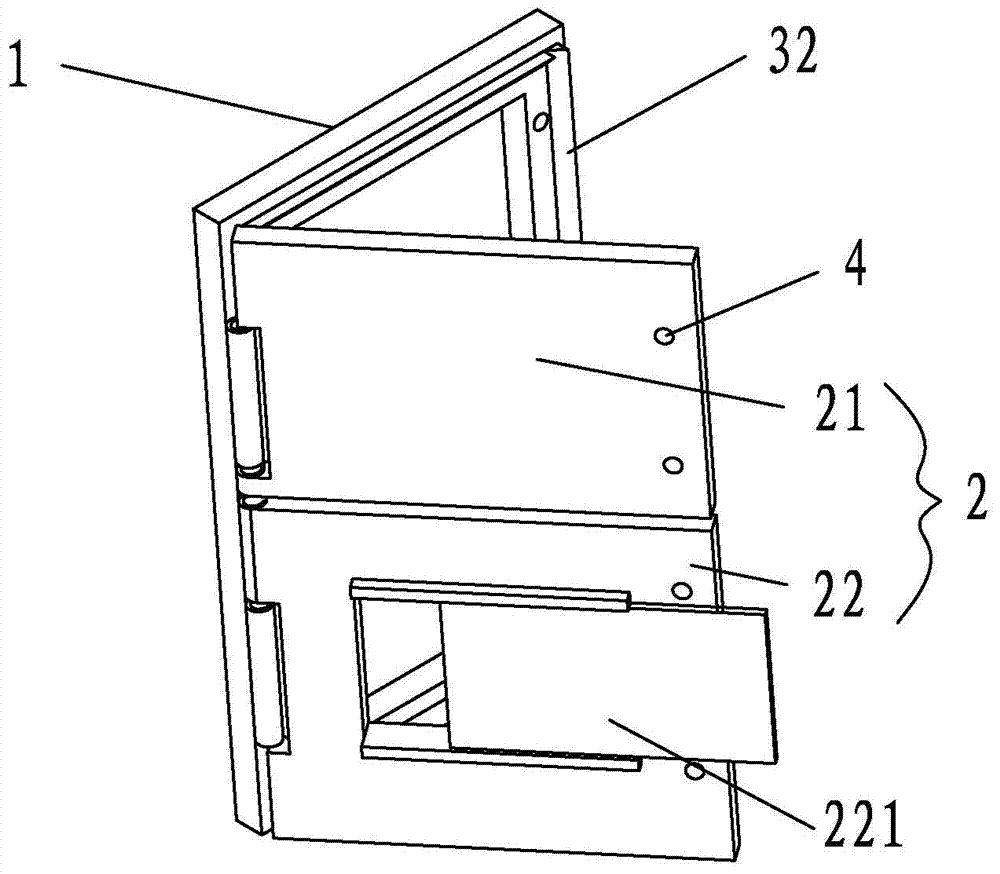

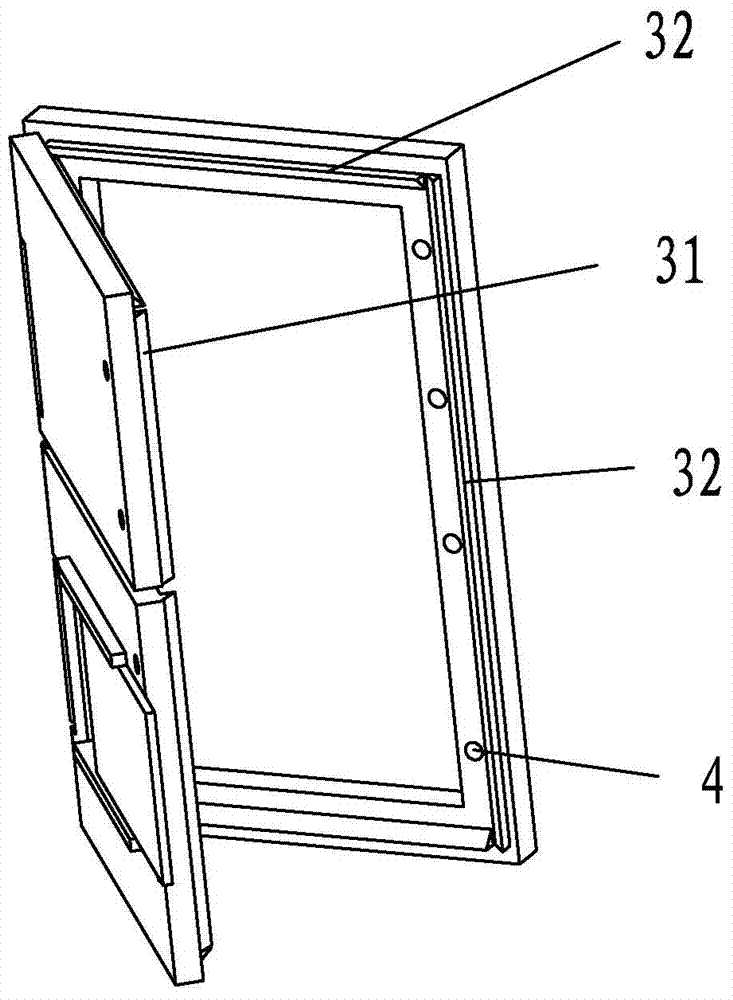

The invention discloses an improved structure for a vibrating screen cover plate. The improved structure comprises a cover plate body installed on the air opening portion of a vibrating screen body. The improved structure is characterized in that the cover plate body is divided into an upper cover plate portion and a lower cover plate portion, a movable window is arranged in the middle of the lower cover plate portion, the left side of the cover plate body is hinged to the vibrating screen body through a hinge, an upper sealing strip is arranged between the upper, lower and right ends of the cover plate body and the vibrating screen body, the vibrating screen body is provided with a lower sealing strip matched with the upper sealing strip in shape, and the cover plate body and the vibrating screen body are fastened through a bolt. The sealing effect of the cover plate is improved, and frequent dismantling for observing whether vibrating screen cloth is blocked or not is avoided.

Description

technical field [0001] The invention relates to a cover plate of a vibrating screen. Background technique [0002] Generally, the vibrating screen cover is fastened on the vibrating screen with bolts to play a sealing and protective role. However, due to the fact that the vibrating screen is blocked in the working process, the screen sometimes needs to be cleaned manually. Because it is the way of bolt tightening, sometimes it is necessary to remove the bolt to see if the screen is blocked. Working conditions, and if the cover is disassembled frequently, it will affect its sealing effect, which is very affecting production efficiency and production environment for some powder vibrating screens. SUMMARY OF THE INVENTION [0003] The technical problem to be solved by the present invention is to provide an improved structure of the vibrating screen cover, which improves the sealing effect of the cover itself, and does not need to be disassembled frequently to observe whether...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B07B1/46F16J15/06

Inventor 庄中海于双王培跃

Owner JIAXING BOHONG NOVEL BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com