Inlaid nut of self-punching type

A technology of inserting nuts and self-piercing holes, which is applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of not meeting the requirements of environmental protection, complex processes, and low work efficiency, so as to ensure health and simple operation process , The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

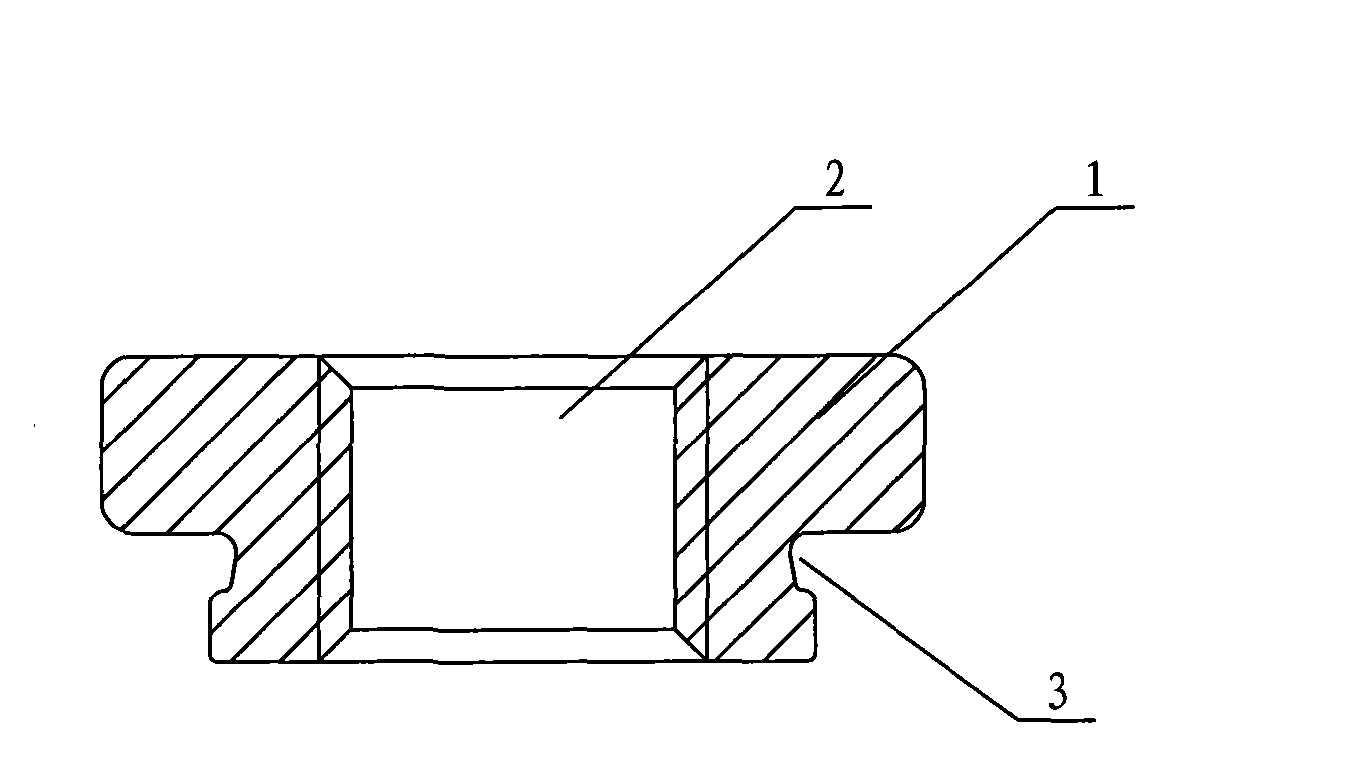

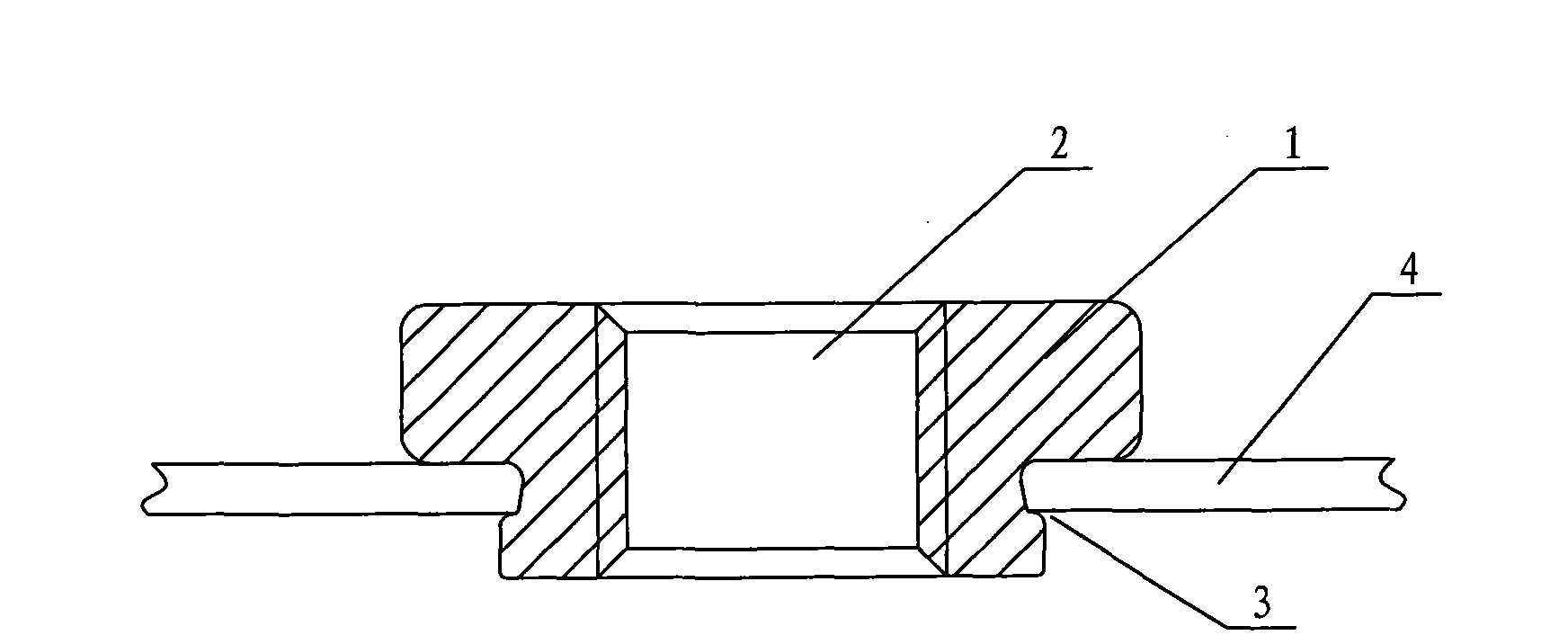

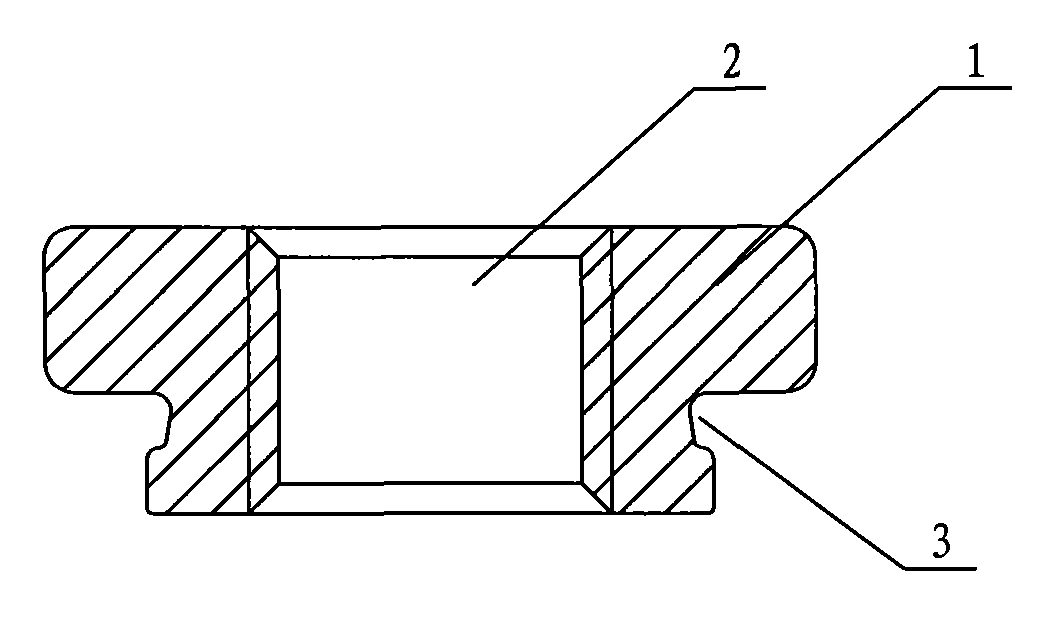

[0013] Depend on figure 1 and figure 2 As shown, the self-piercing inlaid nut is composed of a nut body 1, the nut body 1 is in the shape of a T-shaped plate as a whole, and the nut body 1 is provided with a longitudinal through hole 2, which may be a threaded hole, The nut body 1 is arranged in an inverted stepped layer with a wide top and a narrow bottom. A slot 3 is provided between the upper and lower layers. The slot 3 is relatively arranged. The nut body 1 can be made into a hexahedron, octagon Face body or cylinder etc. shape, described draw-in groove 3 can only be provided with a pair, also can be set to many pairs, if nut body 1 is cylinder shape, then draw-in groove 3 is provided with annular draw-in groove, figure 2 It is a schematic diagram of the structure of the nut body 1 fixed on the sheet metal piece 4 . In a word, the present invention can be made into different shapes and sizes to meet the needs of different customers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com