Welding device for incinerator manufacturing

A welding device and incinerator technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problem of difficult manual welding operation, and achieve the effect of facilitating centralized processing, protecting the production environment, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further described in detail through specific implementation methods:

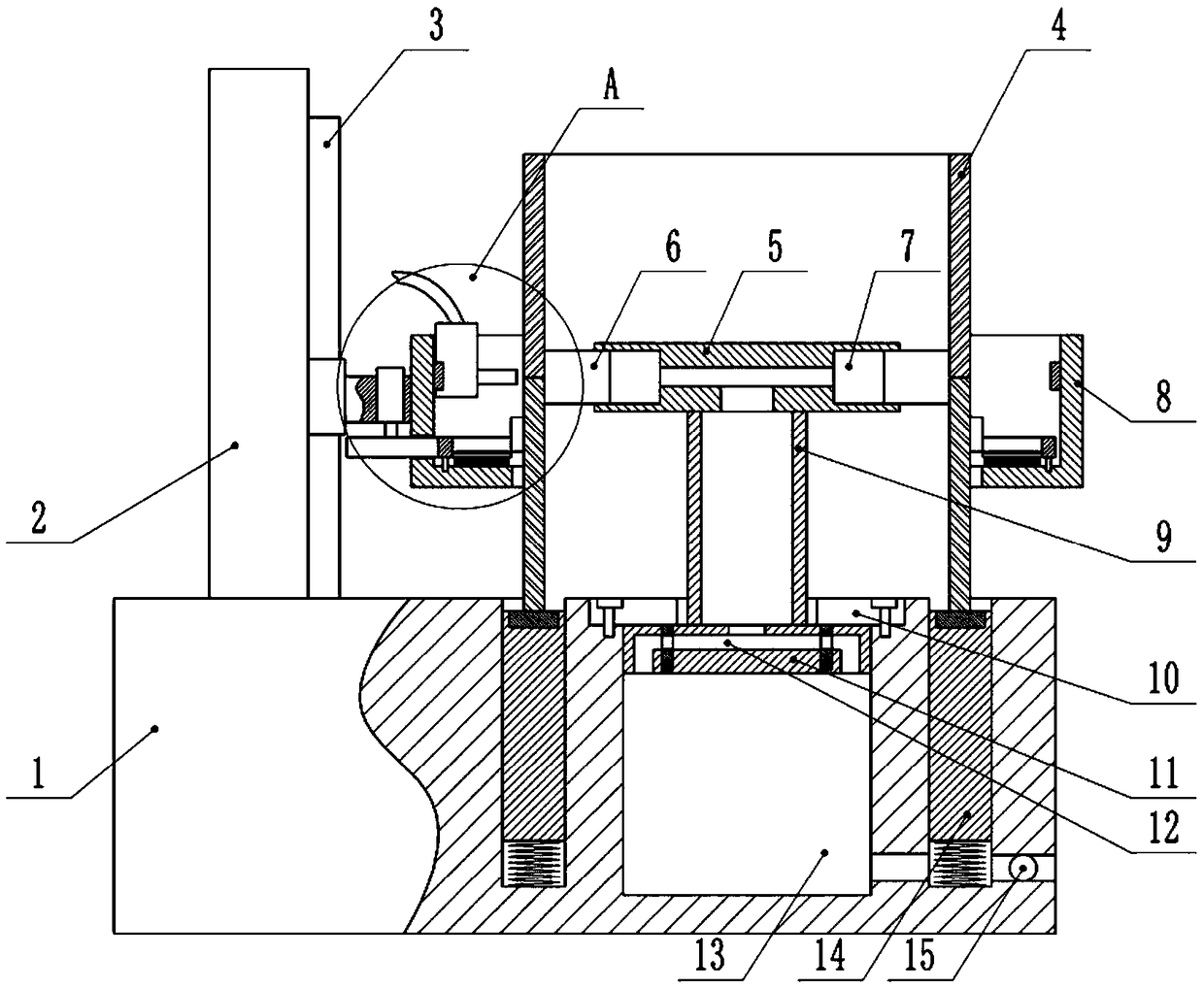

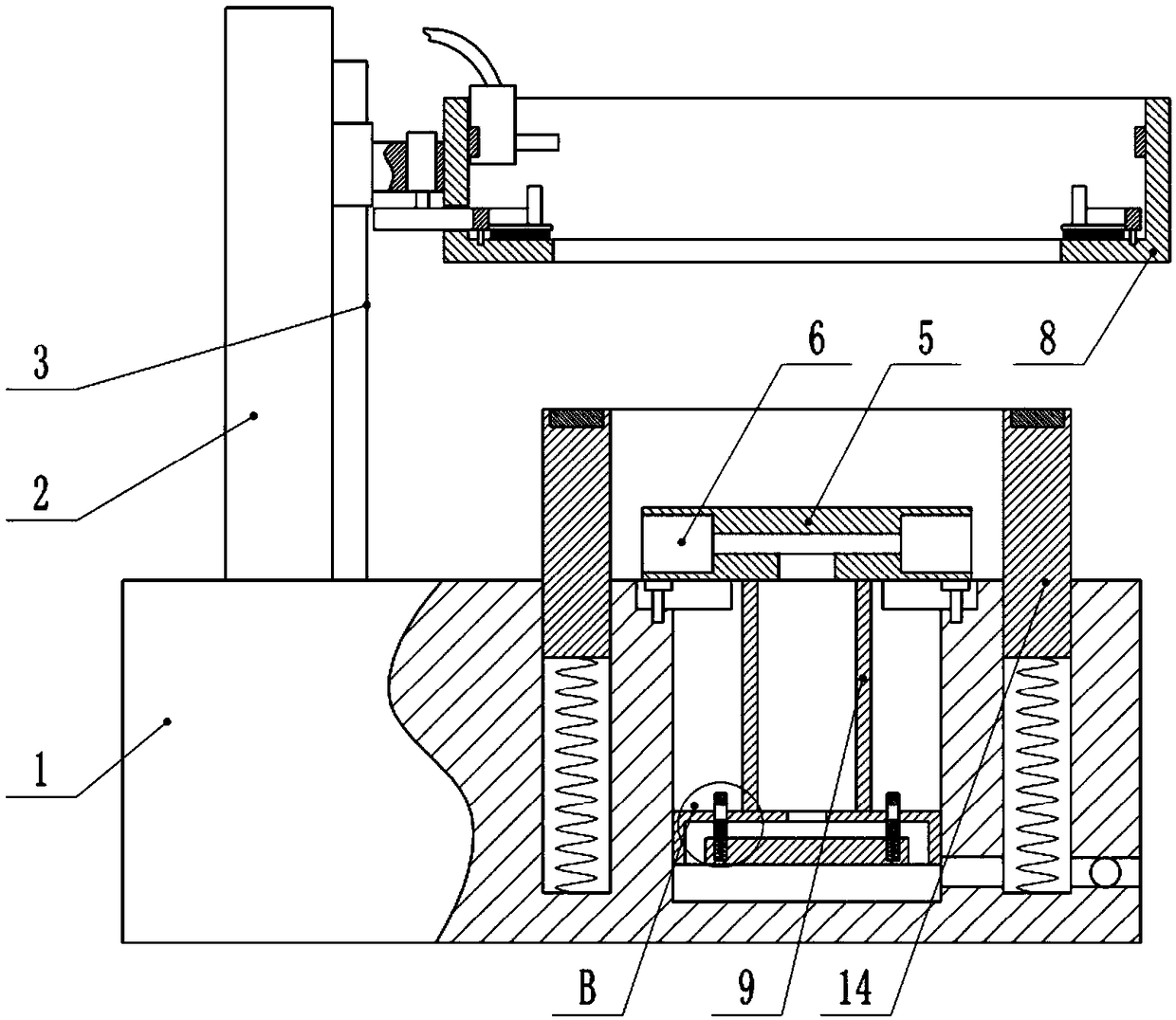

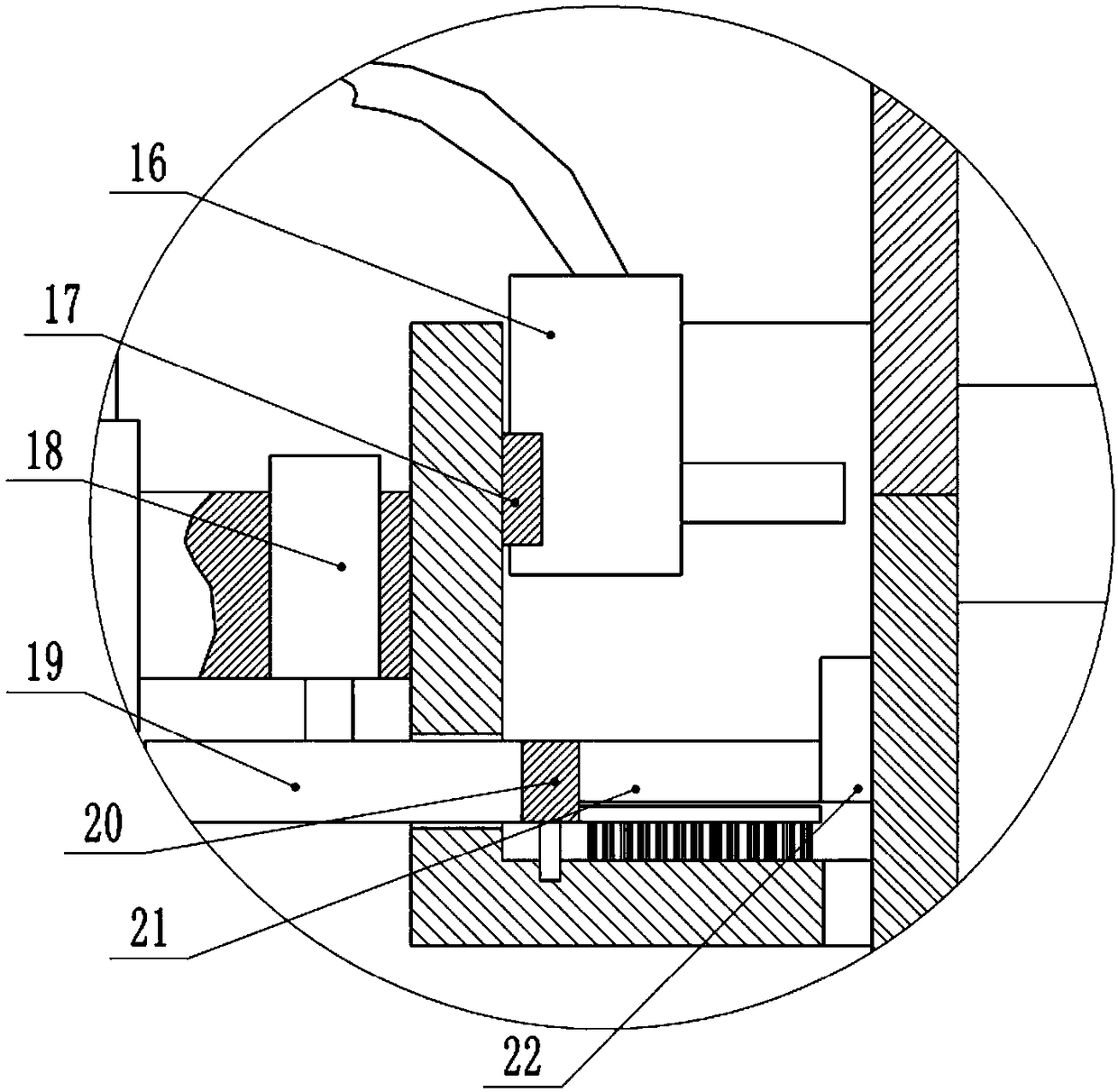

[0018] The reference signs in the drawings of the description include: base 1, support plate 2, slide rail 3, furnace body 4, baffle plate 5, positioning block 6, sliding cavity 7, slag collecting box 8, movable column 9, stop block 10, Piston 11, air channel 12, cylindrical chamber 13, annular plate 14, one-way valve 15, welding head 16, guide rail 17, servo motor 18, transmission gear 19, outer ring gear 20, electric telescopic rod 21, clamping plate 22 , plug body 23, breach 24.

[0019] The embodiment is basically as attached figure 1 , figure 2 Shown: a welding device used for incinerator manufacturing, including a base 1, and a support plate 2 integrally formed on the left side of the upper surface of the base 1. The base 1 is provided with a cylindrical cavity 13 and an annular cavity, the annular cavity and the cylindrical cavity 13 are concentrically arranged and the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com