Mobile ceiling and mobile shed stacking bin

A mobile, ceiling-mounted technology, applied to roofs, building components, buildings, etc., to ensure smooth work, improve work quality and efficiency, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

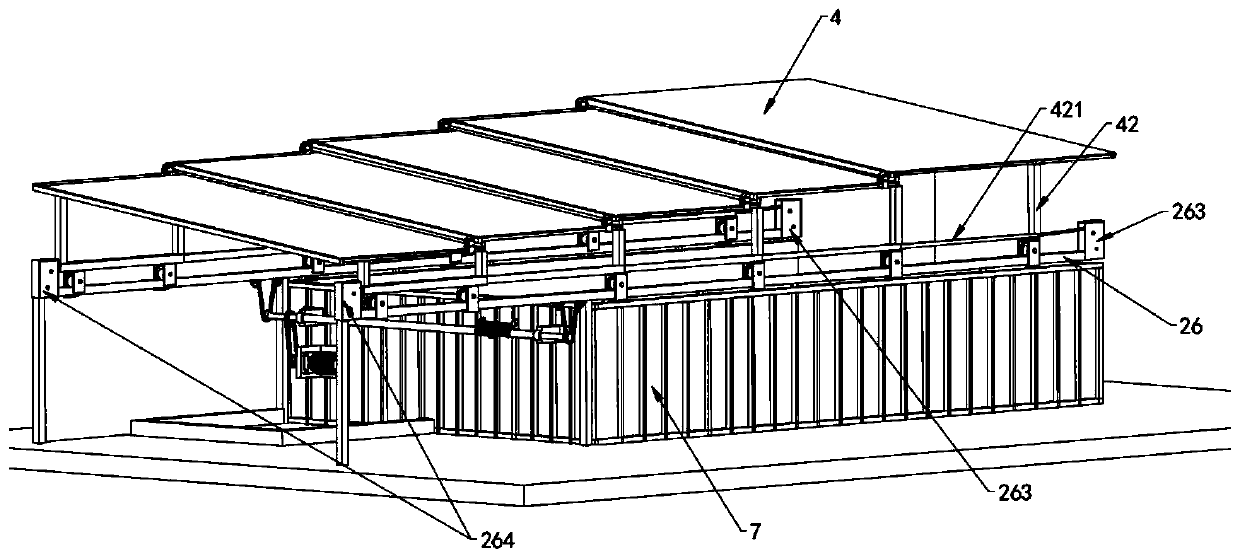

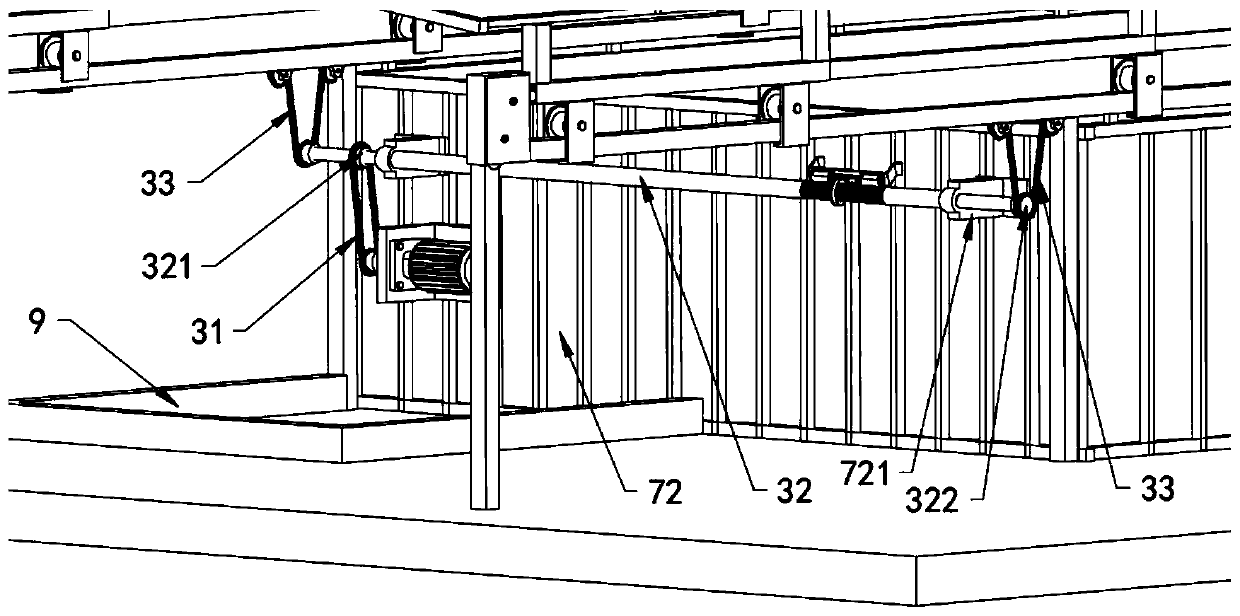

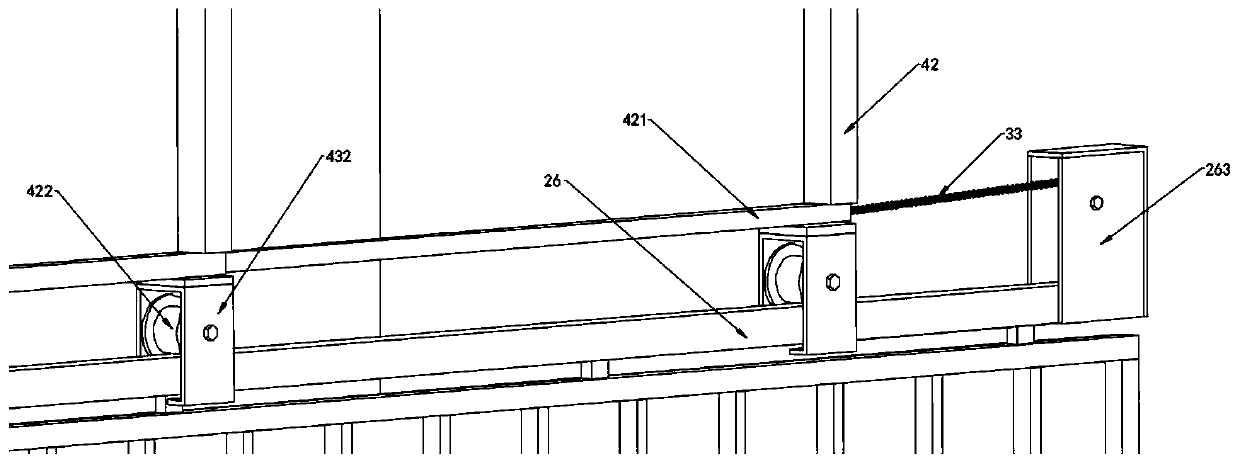

[0095] Such as Figure 1-Figure 4 As shown, the present invention provides a mobile ceiling, which includes a ceiling body 4, a transmission mechanism, and a power mechanism. The ceiling body 4 includes a ceiling panel 41, and a load-bearing column fixedly connected with the ceiling panel 41 42, and the transmission guide rail 421 that is connected with the load-bearing column 42, the transmission mechanism includes the fixed guide rail 26, and the transmission chain 33 arranged inside the transmission guide rail 421 and the fixed guide rail 26, and the transmission chain 33 is fixed in the transmission guide rail 421 , the power mechanism is drivingly connected with the transmission chain 33 , and the transmission chain 33 moves in the fixed guide rail 26 to drive the transmission guide rail 421 to move relative to the fixed guide rail 26 . The power mechanism is an electric motor, and the power mechanism also includes an on switch and an off switch.

[0096] With the above ...

Embodiment 2

[0108] Such as figure 1 , figure 2 and Figure 10 As shown, the present invention also provides a mobile shed storage bin, the mobile shed storage bin includes the mobile ceiling described in Embodiment 1, and a waste liquid collection chamber 8 is arranged below the mobile shed storage bin, and the waste liquid The liquid collection chamber 8 is used to collect the waste liquid accumulated in the material accumulation box 7, which is convenient for the recycling of the waste liquid. The bottom of the storage bin of the mobile shed is provided with a liquid passage hole 711, and the liquid passage hole 711 is used for the material accumulation box The waste liquid accumulated in 7 drops into the waste liquid collection chamber 8, and a waste liquid extraction port 9 is provided outside the storage bin of the mobile shed, and the waste liquid extraction port 9 is connected with the waste liquid collection chamber 8, The waste liquid extraction port 9 extracts the waste liqui...

Embodiment 3

[0111] Such as Figure 1-Figure 8 As shown, the structure of this embodiment is substantially the same as that of Embodiment 2, wherein the same components use the same reference numerals, the difference is that: the ceiling board 41 is provided with 5, and the load-bearing columns of the 5 ceiling boards 41 42 heights and the cross-sectional areas of the transmission guide rails 421 connected to them are different in size, the height changes of the load-bearing columns 42 of the five ceiling panels 41 satisfy the arithmetic difference, and the transverse transmission guide rails 421 connected to the five ceiling panels 41 The change in the size of the cross-sectional area satisfies the differential and / or proportional change, and the change in the height of the load-bearing column 42 of the ceiling plate 41 is inversely correlated with the change in the cross-sectional area of the transmission guide rail 421 connected, that is, in five ceiling plates 41 The higher the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com