Bag isolator for producing carbon

A bag-type and isolator technology, which is applied in the direction of conveyors, transportation and packaging, and conveying bulk materials, can solve the problem of carbon powder loss and other problems, and achieve the effect of preventing dust leakage, ensuring accuracy, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

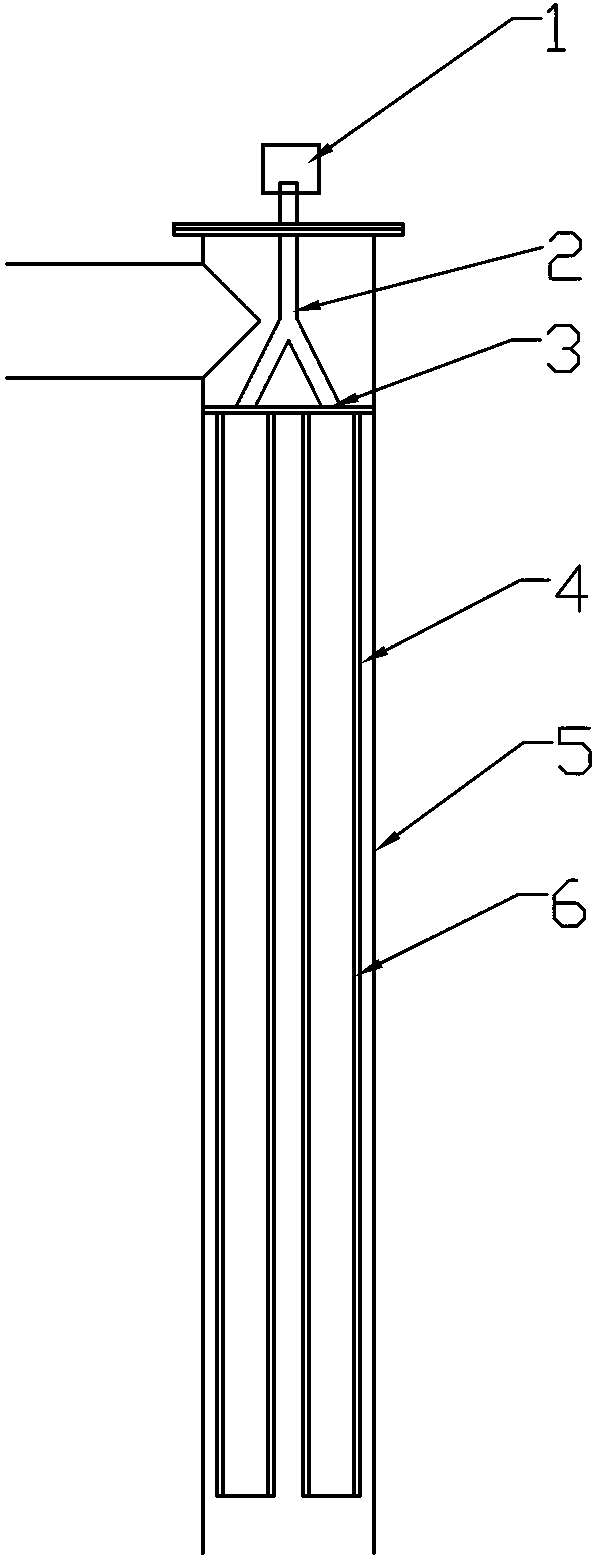

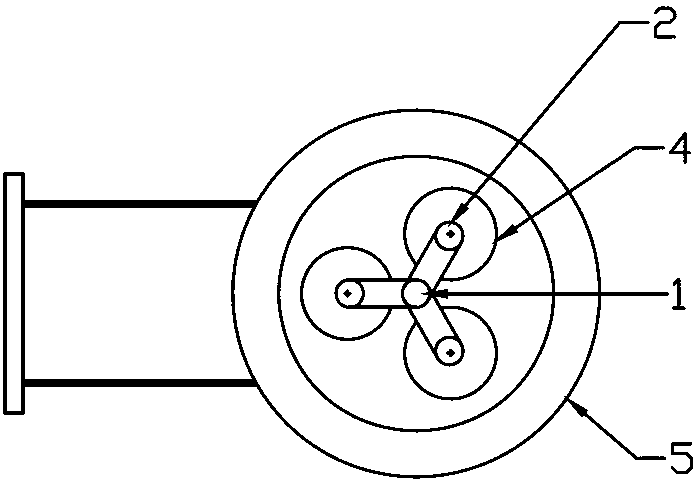

[0010] like figure 1 , figure 2 As shown, a bag-type isolator for carbon production of the present invention includes a pulse solenoid valve 1 , a purge pipe 2 , a fixing frame 3 , a filter bag 4 , a guide tube 5 and a support frame 6 . The guide tube 5 is a circular tube with a lower end opening and a branch opening fixed on the side wall of the upper end. The upper end of the guide tube 5 is provided with an end cover, and the inside of the guide tube 5 is sequentially arranged There are a purge pipe 2, a fixed frame 3 and three filter bags 4, the upper end of the purge pipe 2 passes through the bottom of the upper end of the guide tube 5 and is connected with the pulse solenoid valve 1 arranged on the guide tube, and the lower end is provided with 3 Each opening is connected with three filter cloth bags 4 respectively, the fixed frame 3 is located below the branch opening of the diversion cylinder, and the upper end opening of the filter cloth bag 4 is connected to the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com