Spunlace laminating joint strip and ultra-low emission dust removal filter bag

A technology of spunlace and film coating, which is applied in the direction of filtration and separation, dispersed particle filtration, and dispersed particle separation, etc. It can solve problems such as glue liquid is not easy to dry, PTFE tape falls off, dust leakage, etc., and achieves improved filtration accuracy, firm adhesion, Beautiful seam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

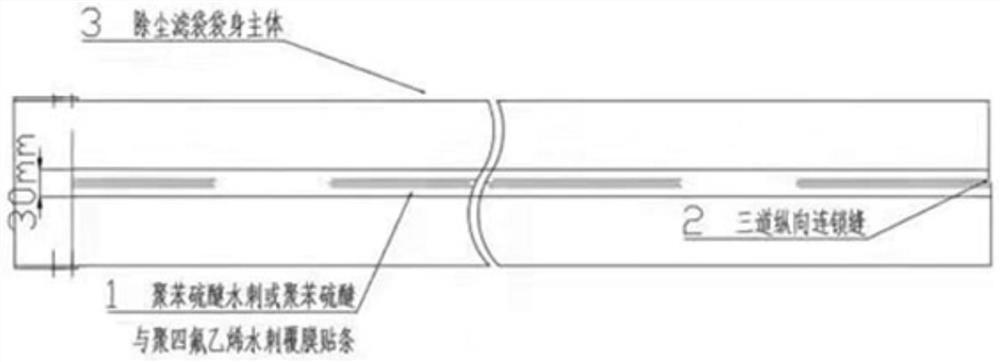

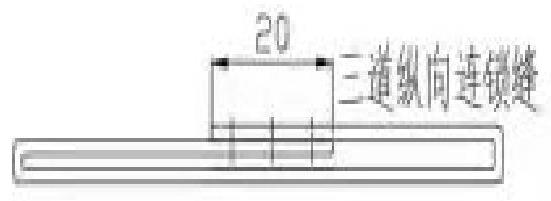

[0021] The following combination figure 1 and figure 2 The present invention is described in detail with specific examples.

[0022] The present invention provides a new type of spunlace film-coated sticker, that is, polyphenylene sulfide or polytetrafluoroethylene mixed polyphenylene sulfide spunlace-coated sticker 1, such as figure 1 As shown, it covers the bag head, bag body, and bag bottom of the dust filter bag to sew pinholes and lap gaps, so as to improve the pinhole leakage prevention at the needle seams of the filter bag and improve the filtration accuracy.

[0023] The present invention further provides an ultra-low emission dust-removing filter bag covered with the aforementioned spunlace-coated film, which includes a main body 3 of the dust-removing filter bag, which is divided into a bag head, a bag body, and a bag bottom. . The polyphenylene sulfide or polytetrafluoroethylene mixed polyphenylene sulfide spunlace coating strip 1 is pasted on the main body 3 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com