Automatic dust-free batching scale

A batching scale and automatic technology, applied in the direction of special scales, measuring devices, instruments, etc., can solve the problems of easy human error, high labor intensity of workers, complex equipment structure, etc., to achieve easy to push the batching barrel, avoid human errors, and equipment The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

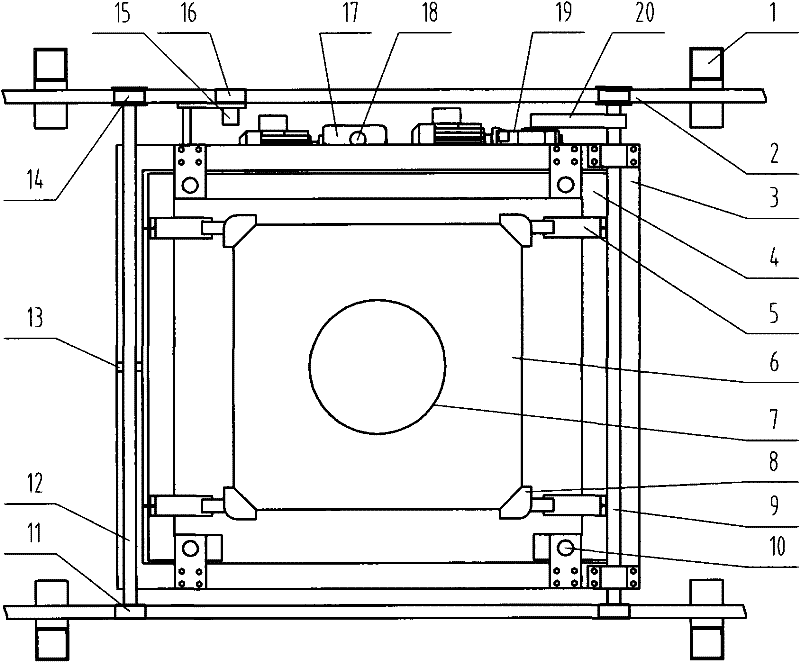

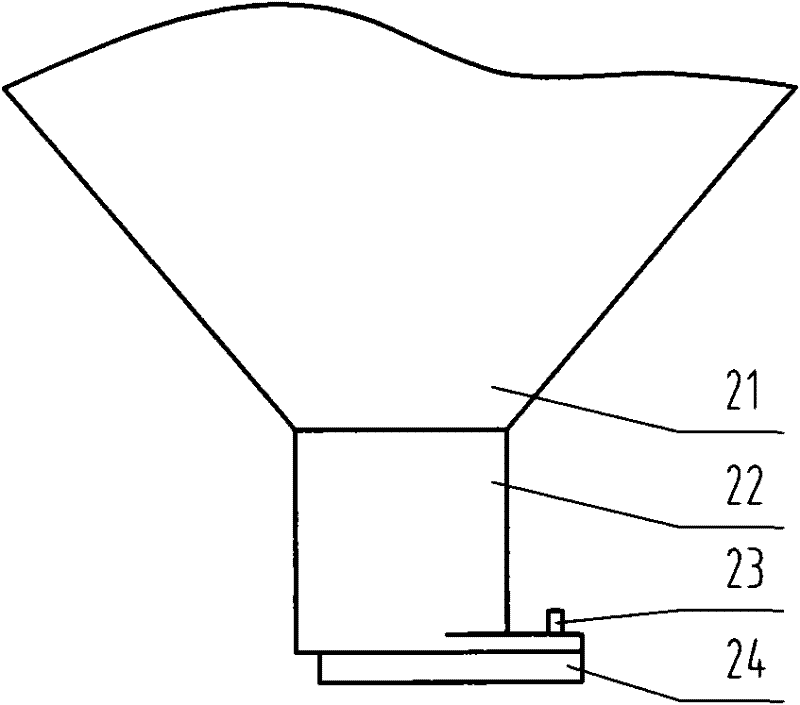

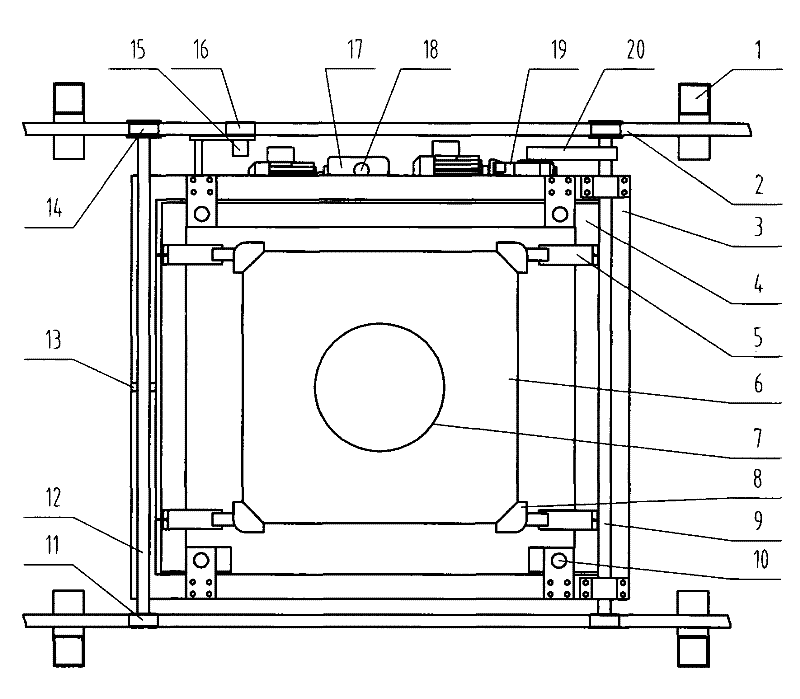

[0013] As shown in the figure, the present invention consists of a support (1), a feed bin (21), a feeding device (22), a guide rail (2), a horizontal moving frame (3), a lifting frame (4), a load cell (5), The batching barrel (6) and the control system are composed. The silos (21) are horizontally arranged and installed on the support (1). The lower part of each silo (21) is connected to the feeding device (22). On the support (1), the height is higher than the batching barrel (6), the horizontal movement frame (3) is movable laterally on the guide rail (2), and the lifting frame (4) is installed on the lead screw (10) of the horizontal movement frame (3) Above, there is a gap in the front of the lifting frame (4), and 4 load cells (5) are installed on both sides of the lifting frame (4). When the lifting frame (4) is pushed in or pulled out, the lifting frame (4) is at a low position, and the height of the connecting piece on the load cell (5) is lower than the lug (8) of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com