Incoming and outgoing sand roasting device

A technology for roasting and sanding pipes, which is applied in casting molding equipment, cleaning/processing machinery for casting mold materials, metal processing equipment, etc. It can solve problems such as heat loss, achieve easy operation, ingenious conception, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

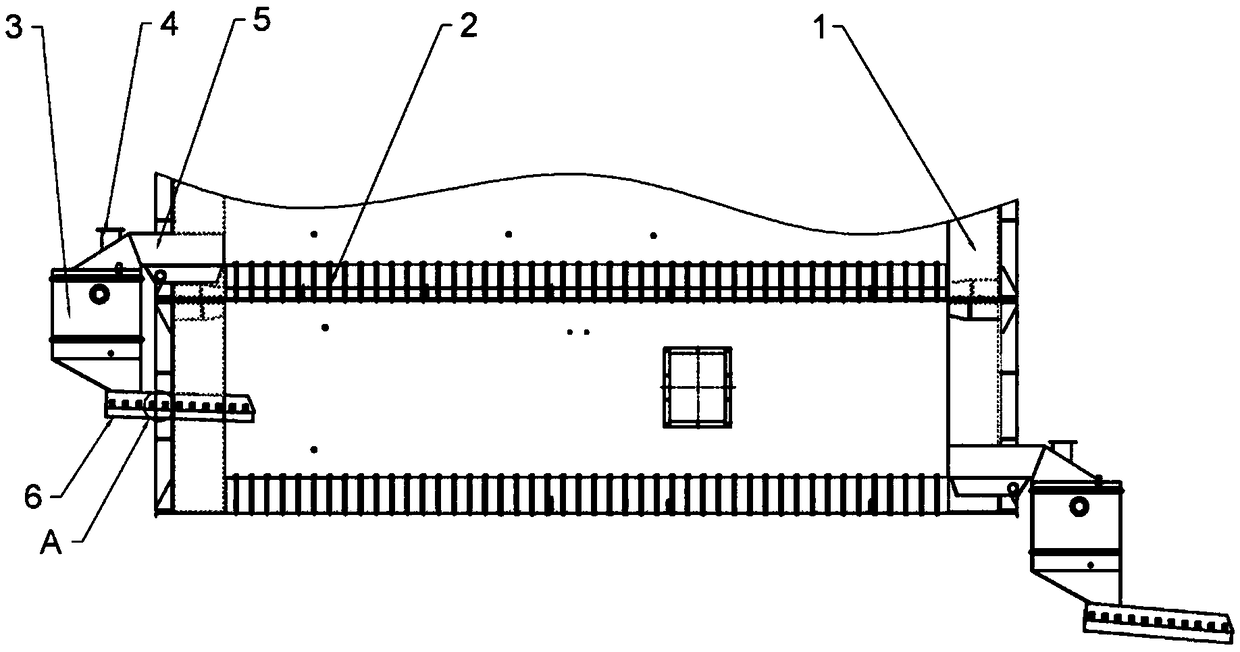

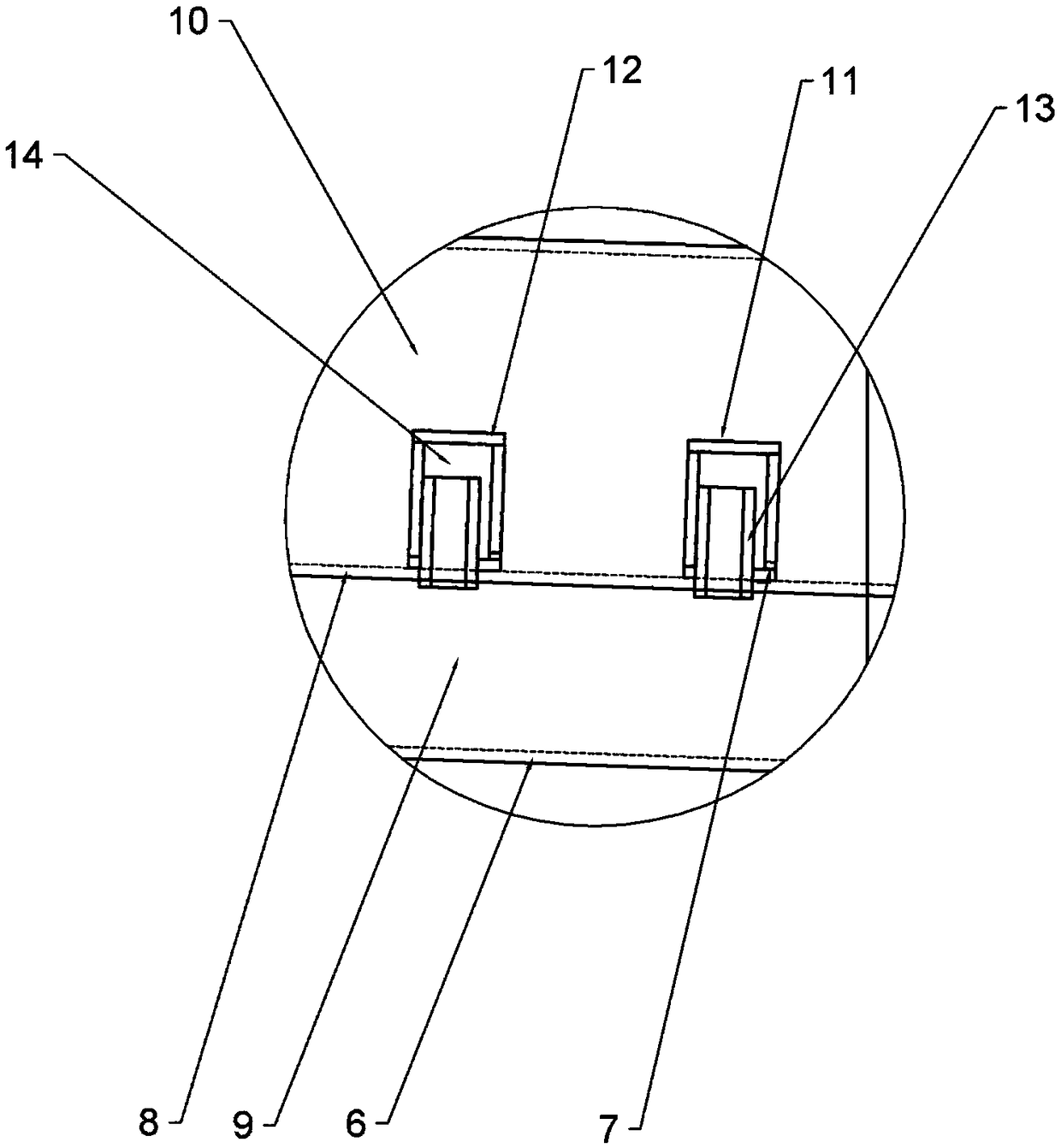

[0022] The reference signs in the drawings of the description include: furnace body 1, sealing plate 2, closed box 3, high temperature level gauge 4, sand inlet pipe 5, sand outlet pipe 6, air outlet 7, partition plate 8, air chamber 9, A sand outlet chamber 10, a connecting piece 11, a cover body 12, a connecting pipe 13, and an air duct 14.

[0023] The embodiment is basically as attached figure 1 Shown: a roasting sand inlet and outlet device, including a furnace body 1 and an inlet and outlet sand structure. In this embodiment, the body of furnace 1 is a horizontal roasting furnace, and a sealing plate 2 is arranged in the lateral direction of the body of furnace 1. The sealing plate 2 separates the body of furnace 1 into two parts, that is, the body of furnace 1 is divided into an upper roasting chamber and a baking chamber by the sealing plate 2. The lower roasting chamber is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com