Biological matter straw burning-gasifying feeding apparatus

A biomass straw and feeding device technology, which is applied to the gasification feeding device and the biomass straw burning field, can solve the problems of inability to enter the feeding device smoothly, low bulk density, different sizes, etc. Good adaptability and wide size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

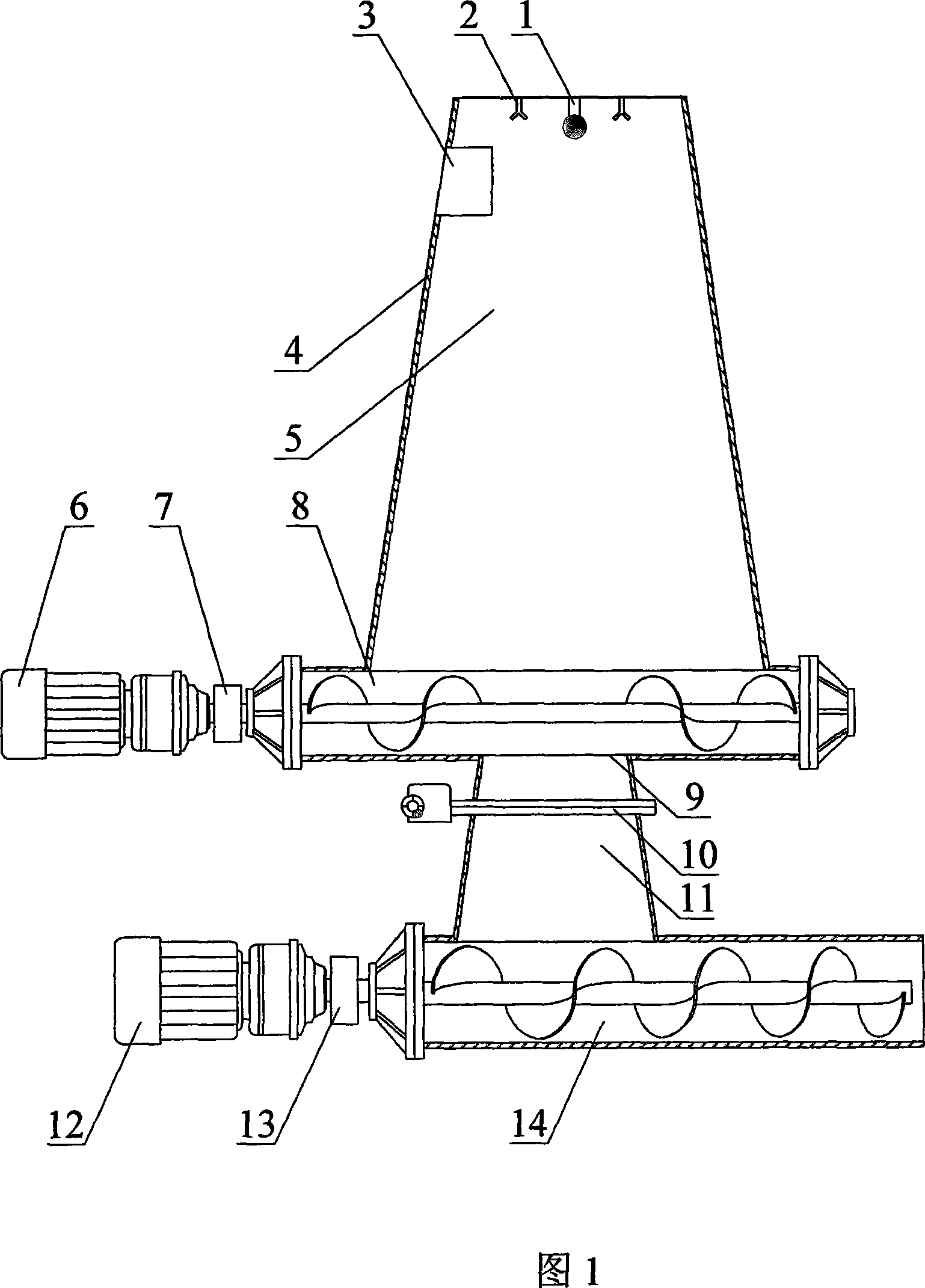

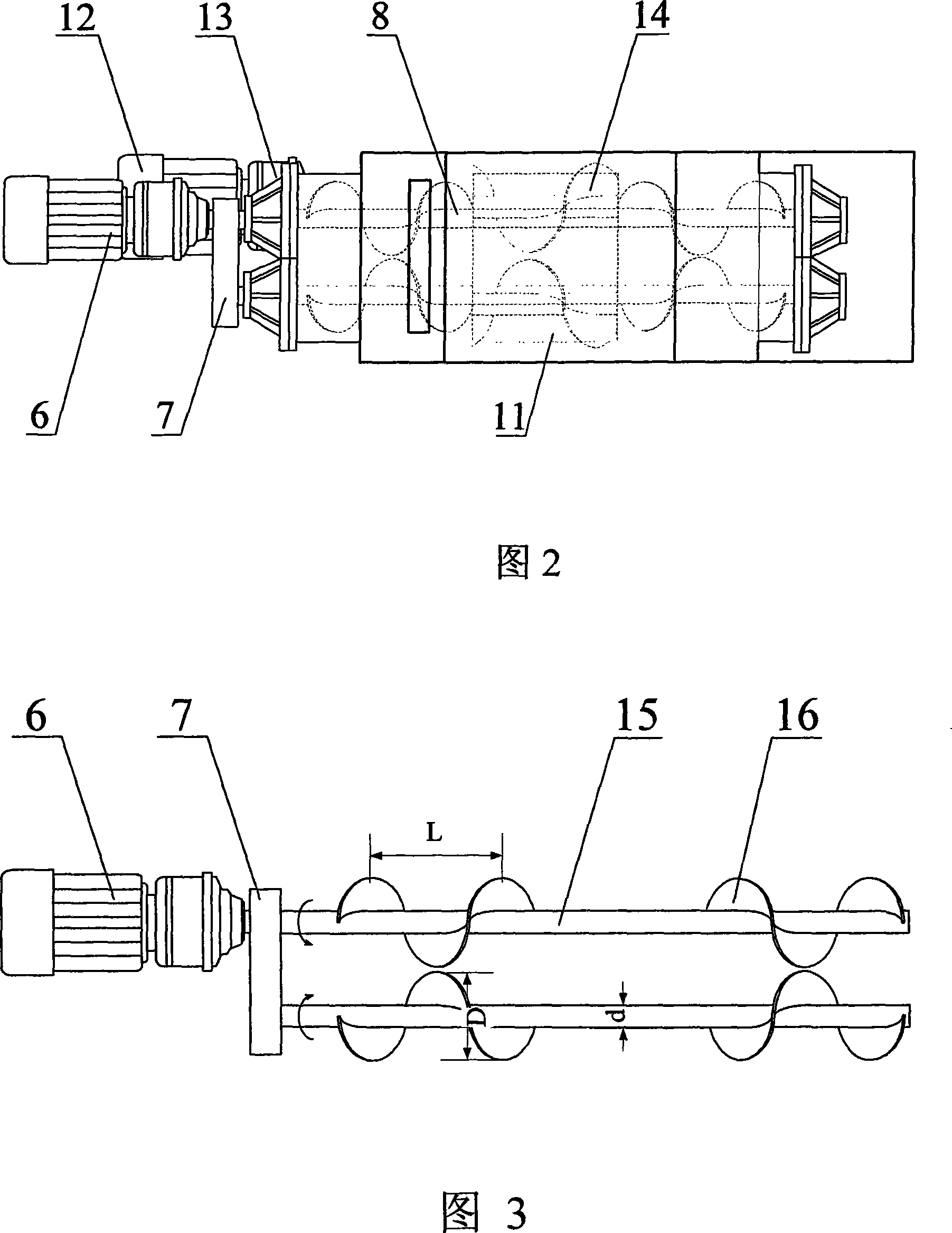

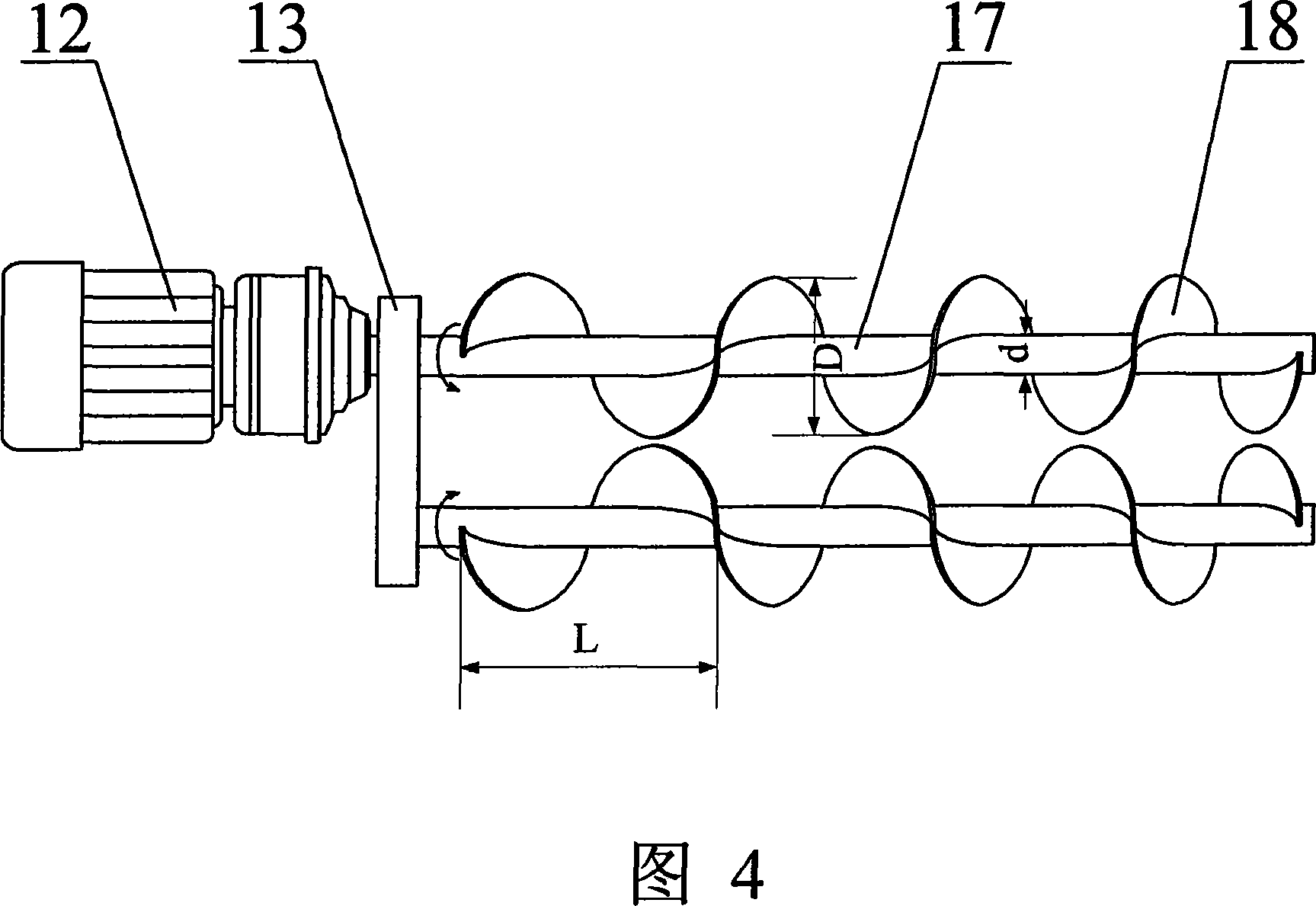

[0022] The feeding and device of the present invention are mainly composed of a feed bin 5, a double screw feeder 8, an intermediate hopper 11 and a double screw conveyor 14. The chopped and pretreated biomass straw of 10-200 mm is fed into the silo 5, fed by the double-screw feeder 8 at the bottom, and falls into the middle hopper 11, and then the biomass is transported by the double-screw conveyor 14 at the bottom of the hopper. The straw is conveyed into the material equipment such as biomass combustion and gasification.

[0023] The silo 5 is in the shape of a tower, the front and rear panels are vertical, and the side panels 4 are inclined with an inclination angle of 5-10°, which can effectively prevent the materials from forming "bridges" and "arches" in the silo 5; An industrial TV monitoring device 1 and a high-pressure water spraying device 2 are arranged in the center. Once an open flame is detected in the material layer, water can be sprayed immediately to eliminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com