Patents

Literature

78results about How to "Improved size adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer hollow microsphere and preparation method thereof

The invention relates to a polymer hollow microsphere and a relative preparation method. The preparation method comprises using emulsion polymerization method to prepare water absorbing polymer, using core-shell polymerization to prepare the polymer microsphre coated by water absorbing polymer, using the reaction character of functional monomer at the surface of the polymer microsphere and atomization drying to obtain the polymer hollow microsphere with ideal size, many internal hollow microspheres and negative pressure in the hollow microsphere. The preparation method has low energy consumption, controllable preparation, various products, controllable grain size of hollow microsphere, better size adaptability, high stability, high production efficiency, no generation of waste water, waste gas and waste slag, low pollution and environment protection, whose polymer hollow microspheres have better acie and alkali resistnace. The invention is suitable for construction material and paint, with wide application and practical value.

Owner:金小刚

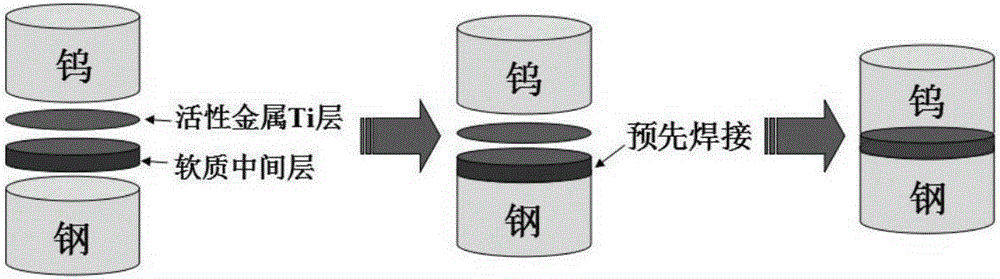

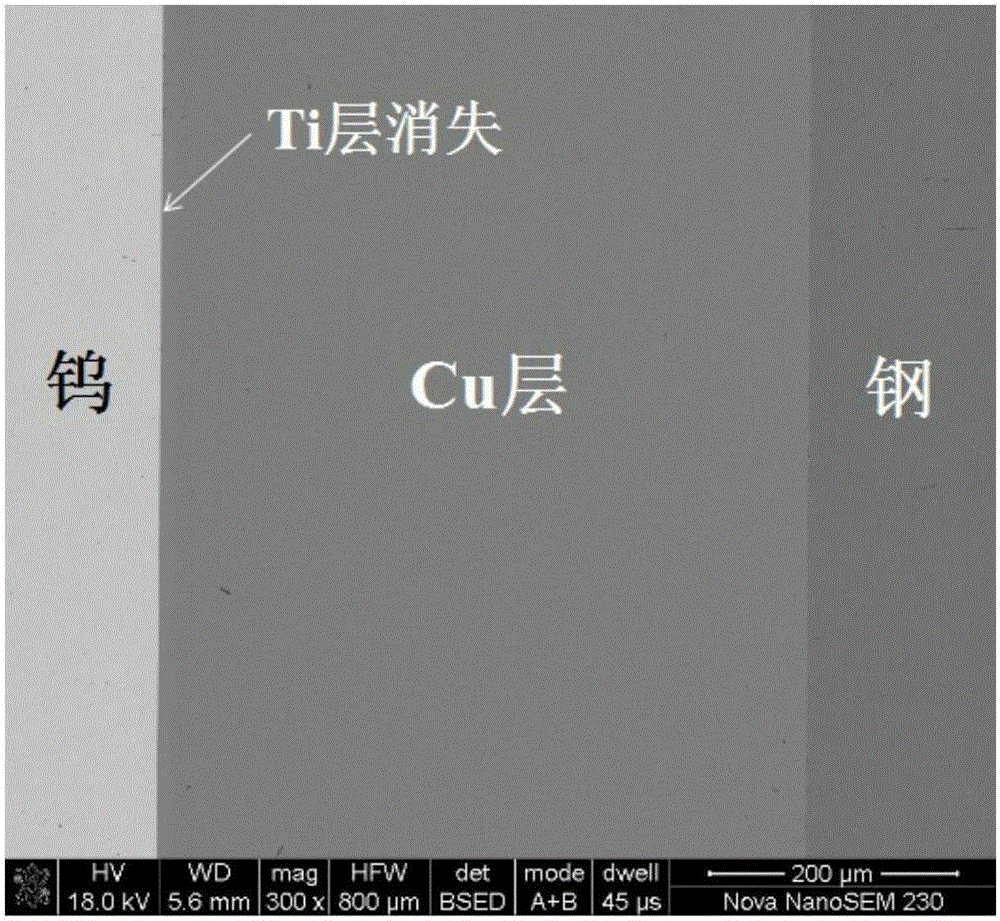

Tungsten/transition layer/steel composite material and low-temperature and low-pressure active diffusion connection preparation method thereof

ActiveCN105346161AHigh strengthReduce residual stressMetal layered productsNon-electric welding apparatusLarge jointTitanium

The invention relates to a tungsten / transition layer / steel composite material and a low-temperature and low-pressure active diffusion connection preparation method thereof, and belongs to the technical field of preparation of composite materials. Raw materials used for preparing the tungsten / transition layer / steel composite material comprise a tungsten substrate, an active metal Ti layer, a soft interface layer and a steel substrate. The method comprises the following steps: welding the soft interface layer and the steel substrate through a traditional welding process, sequentially superposing the obtained layer to the active metal Ti layer and the tungsten substrate, and carrying out vacuum diffusion connection to prepare a tungsten substrate / titanium layer / soft interface layer / steel substrate connecting piece which is the high-performance tungsten / steel composite material. The tensile strength of the composite material is greater than or equal to 386MPa. The composite material has a reasonably designed structure, and the problems of large joint residual stress, low strength and high requirements of welding conditions of present tungsten / steel connecting pieces are solved through matching of the structure with the method. The preparation method is simple, and is convenient for industrial application.

Owner:CENT SOUTH UNIV

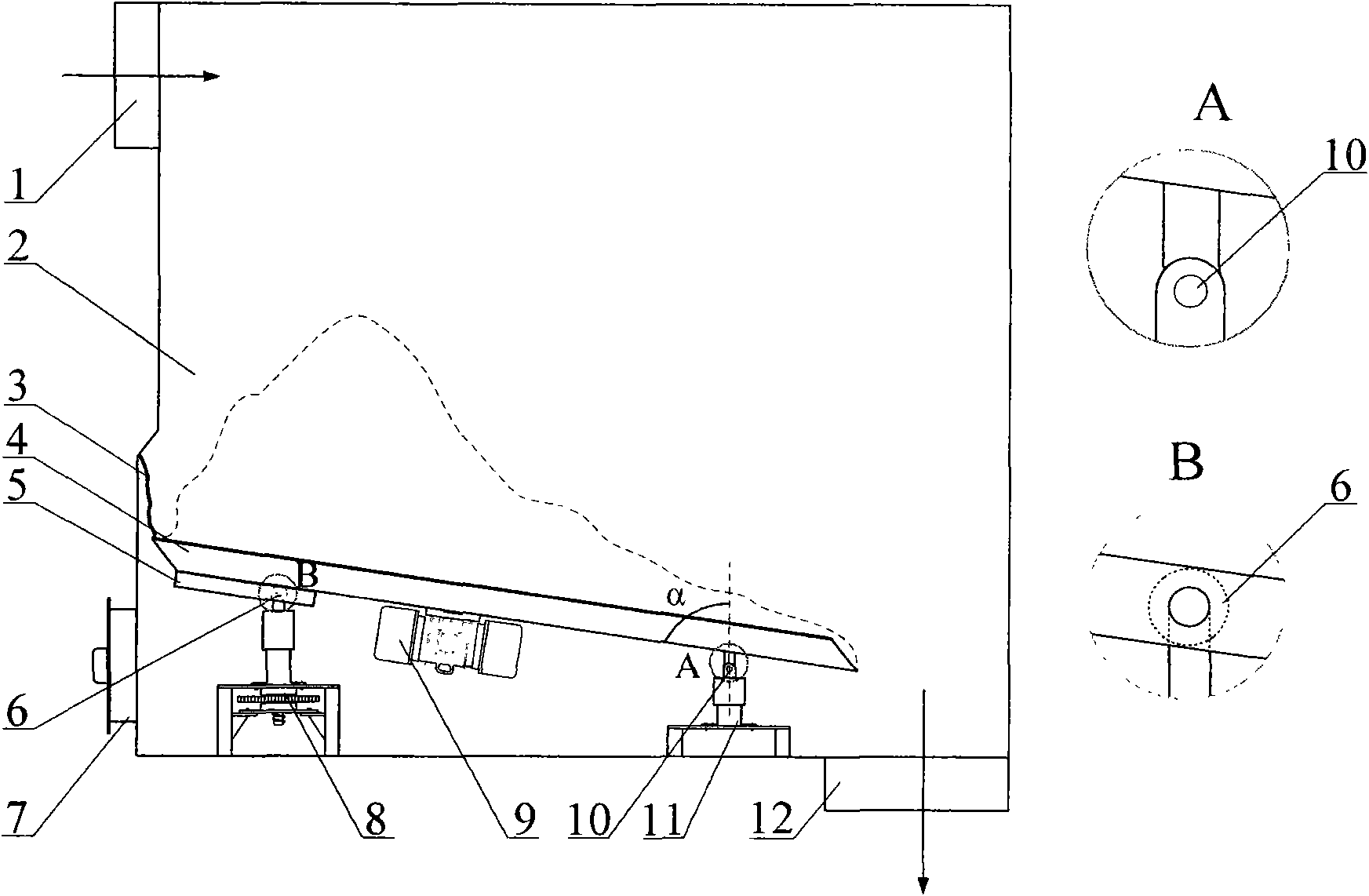

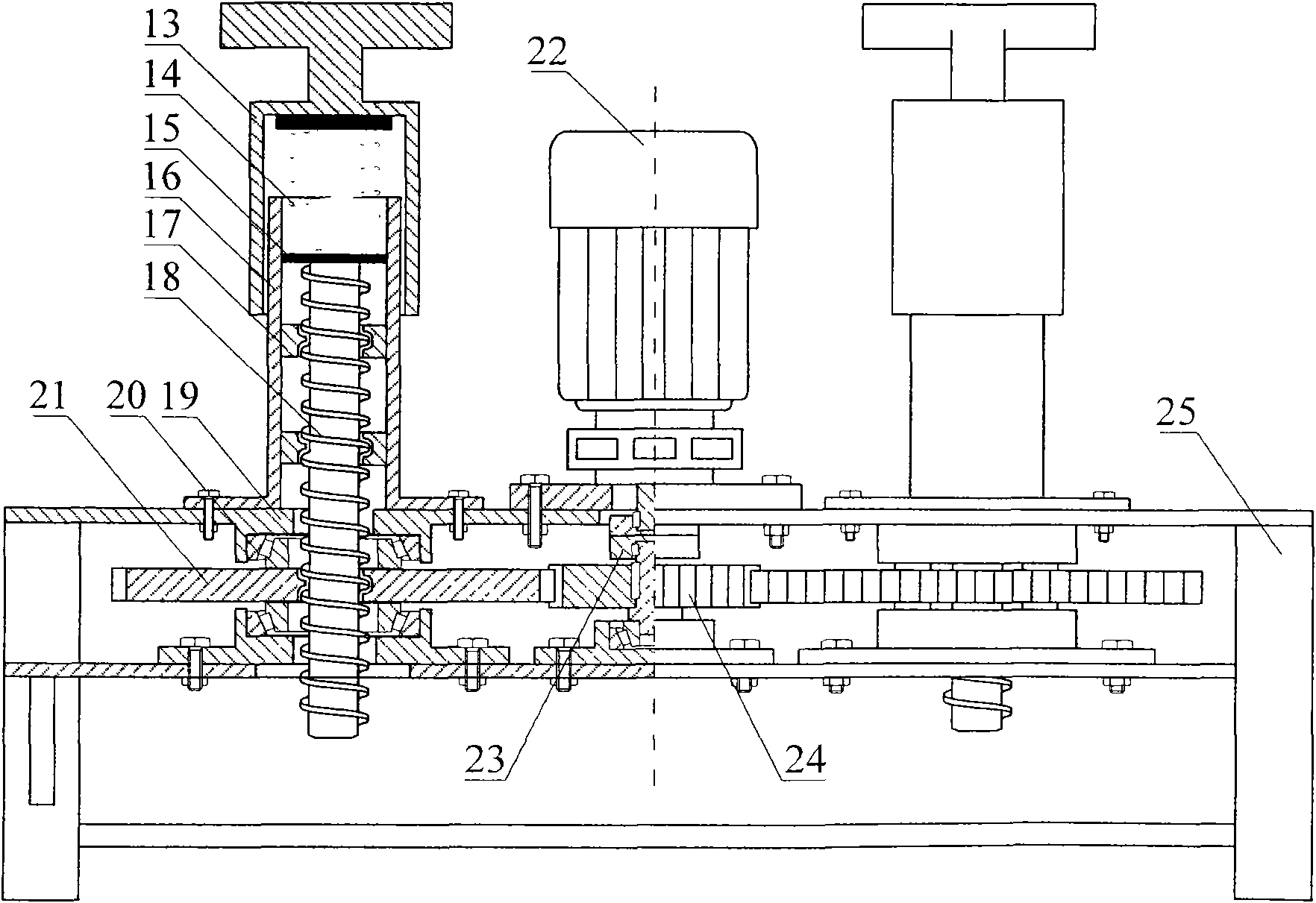

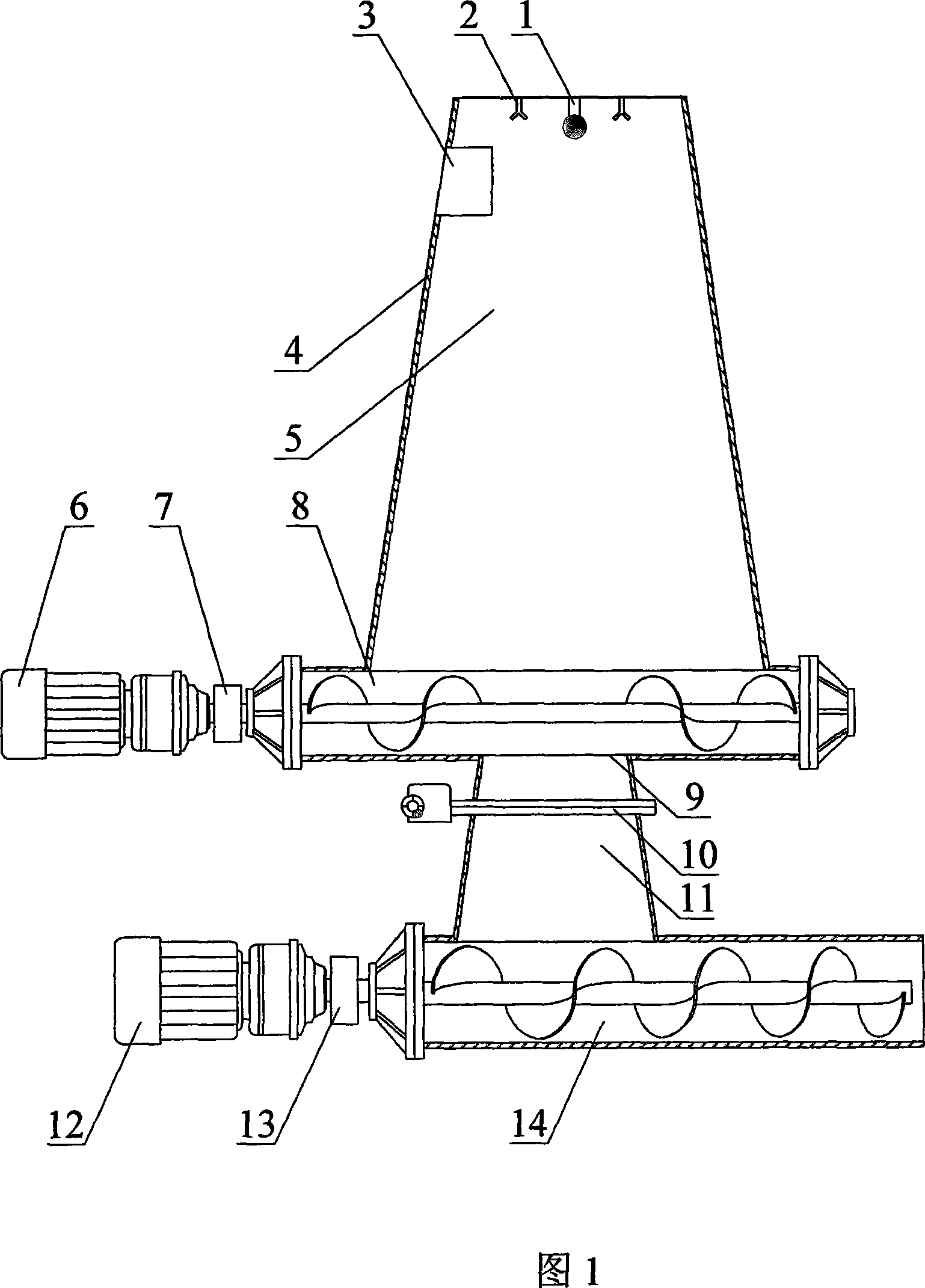

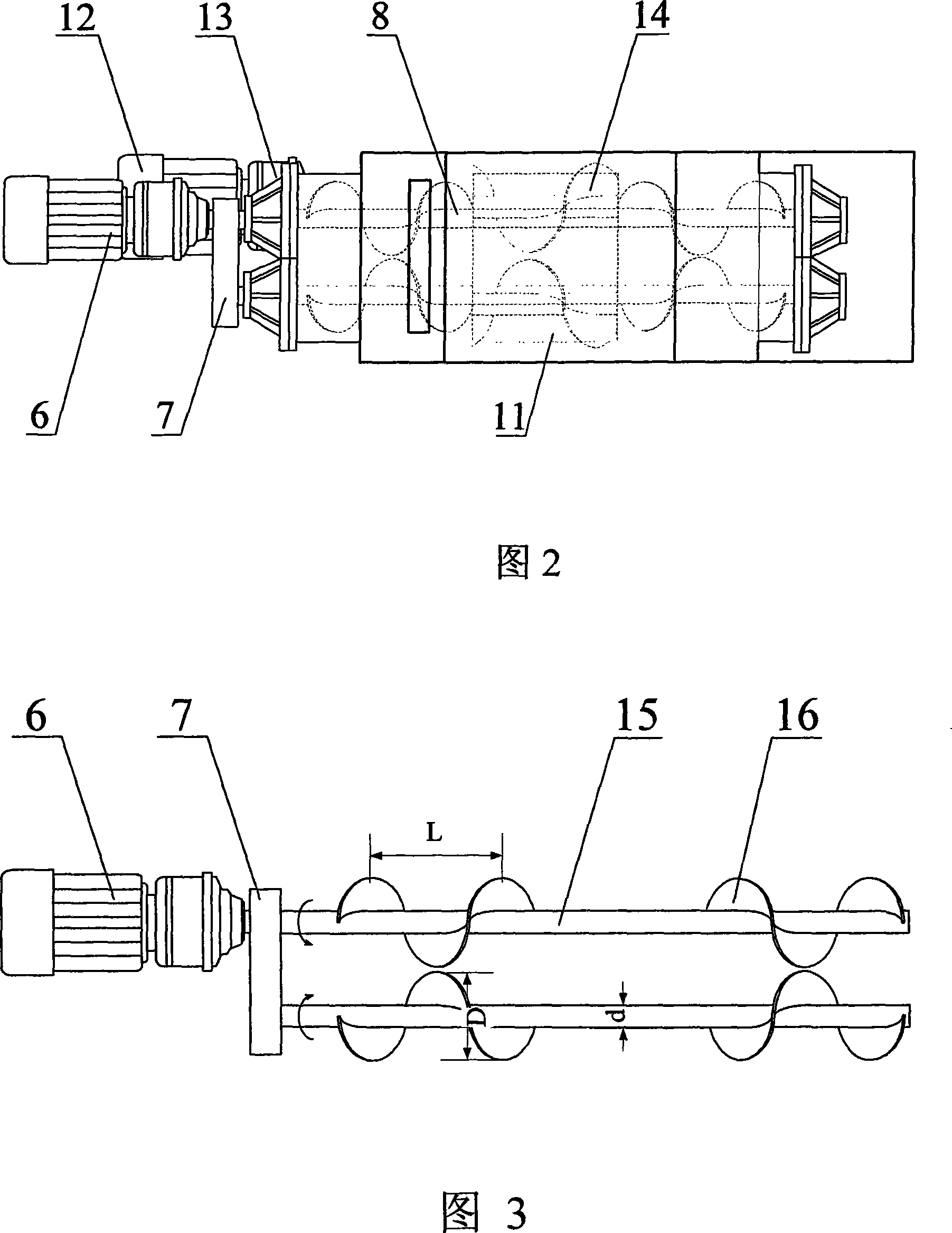

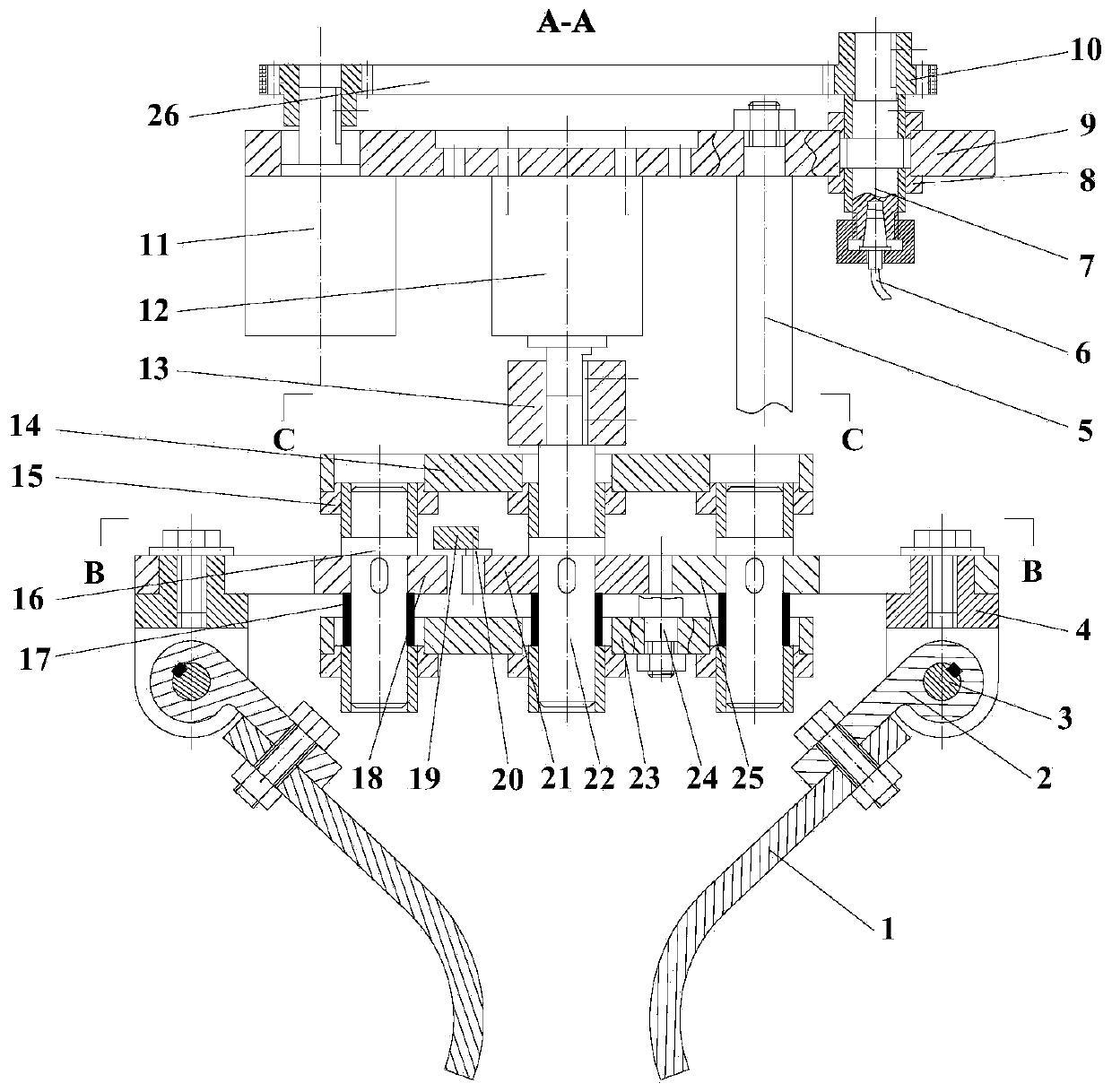

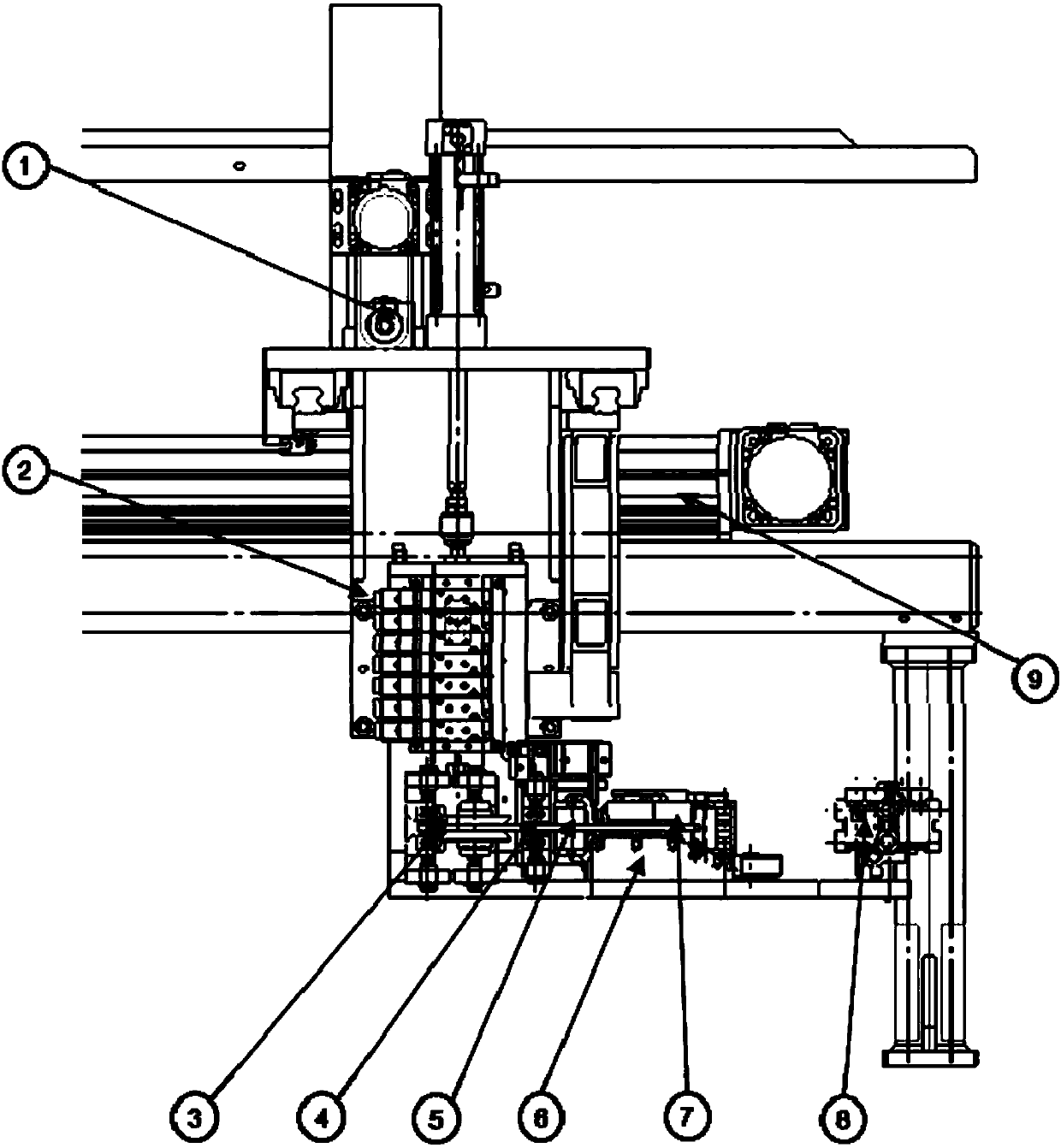

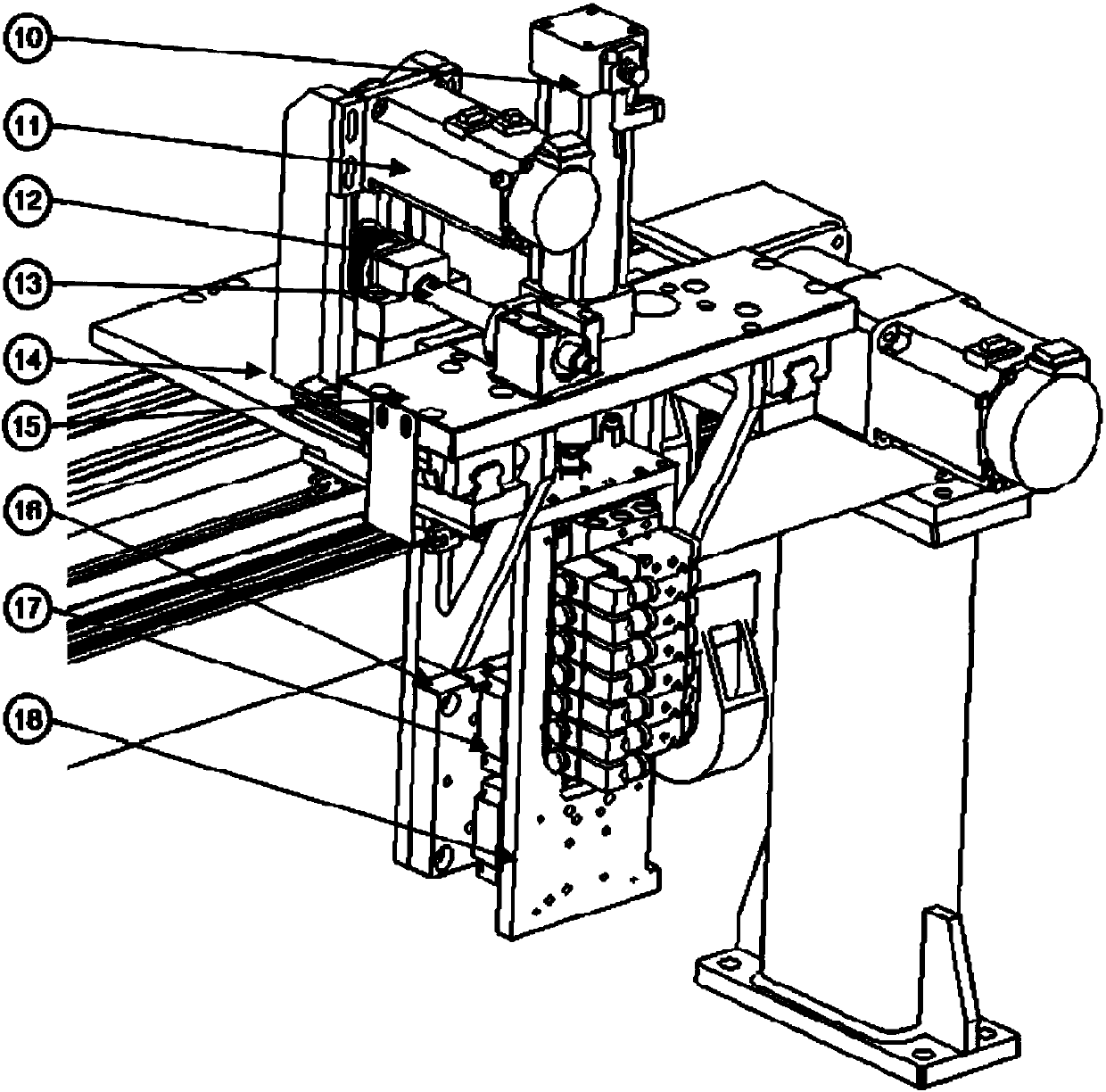

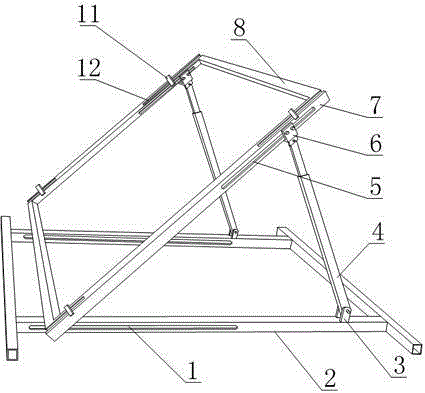

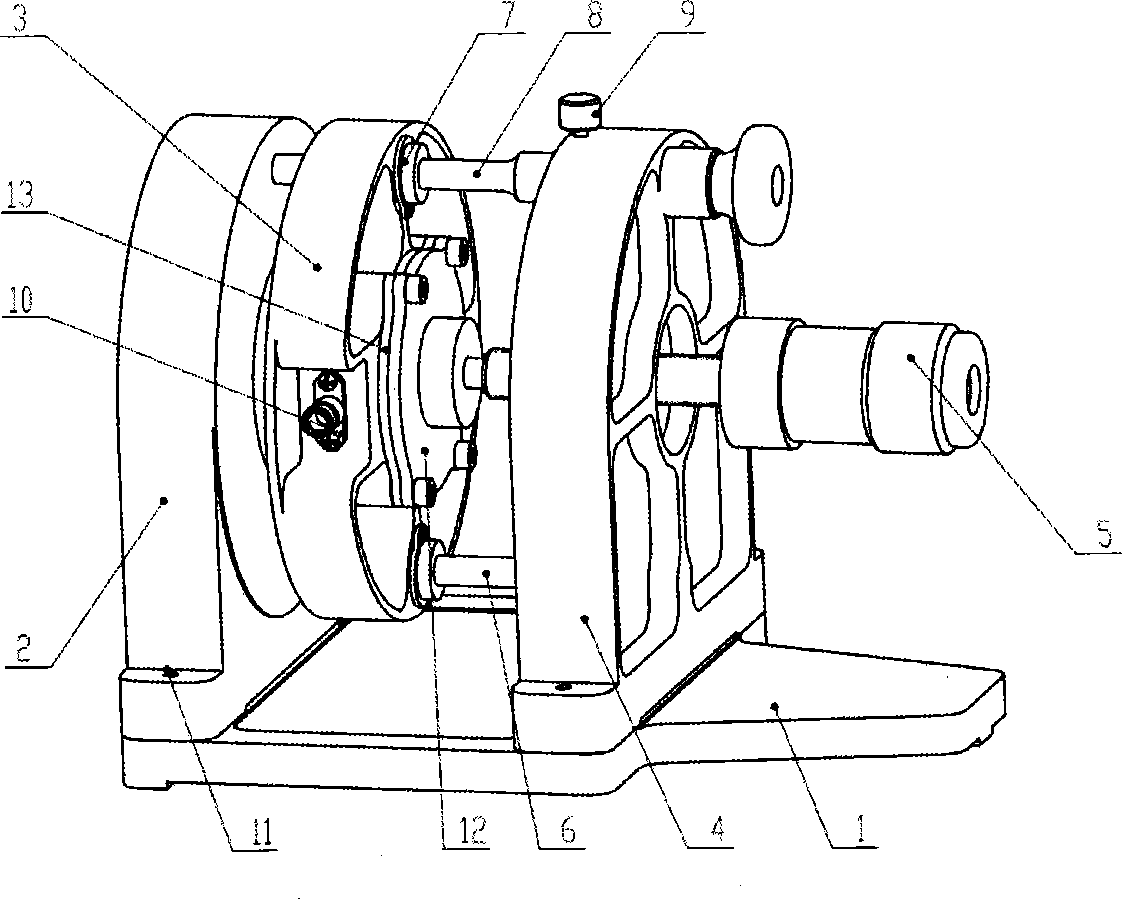

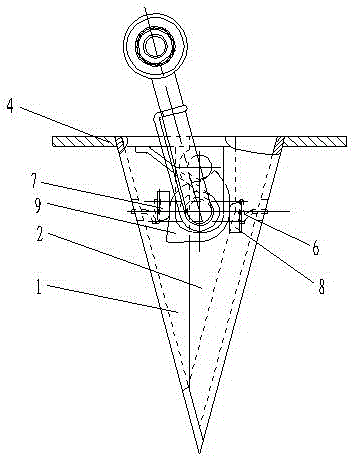

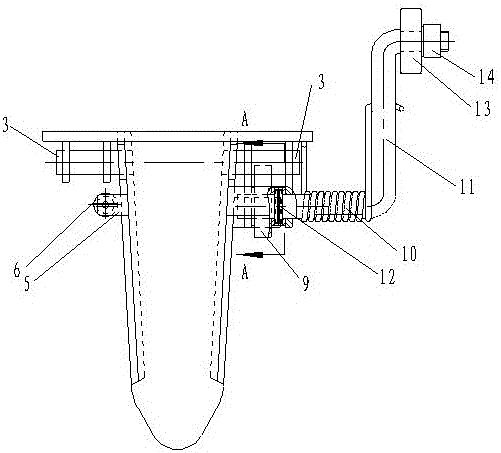

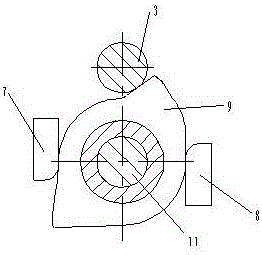

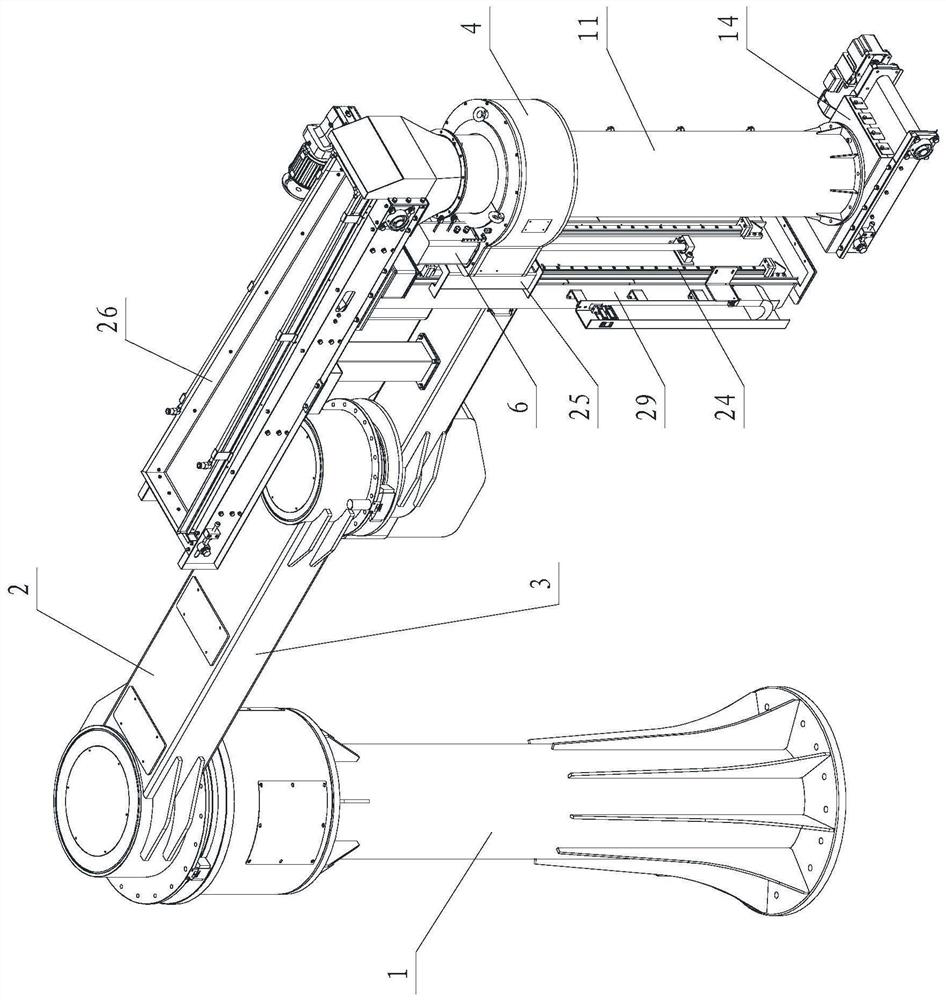

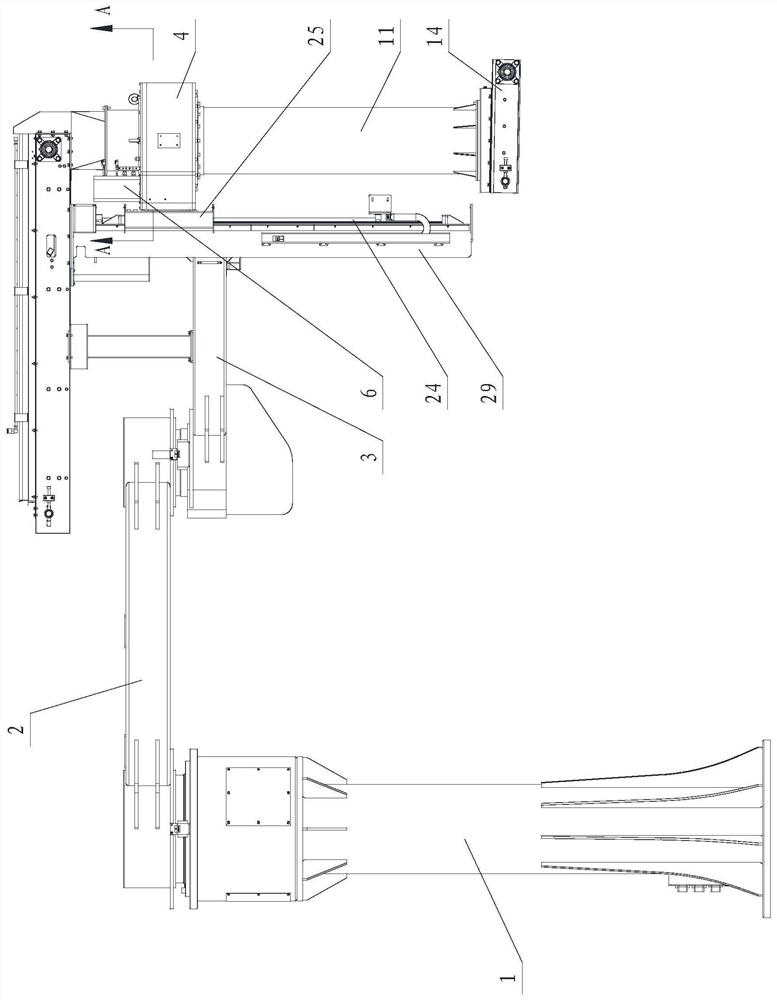

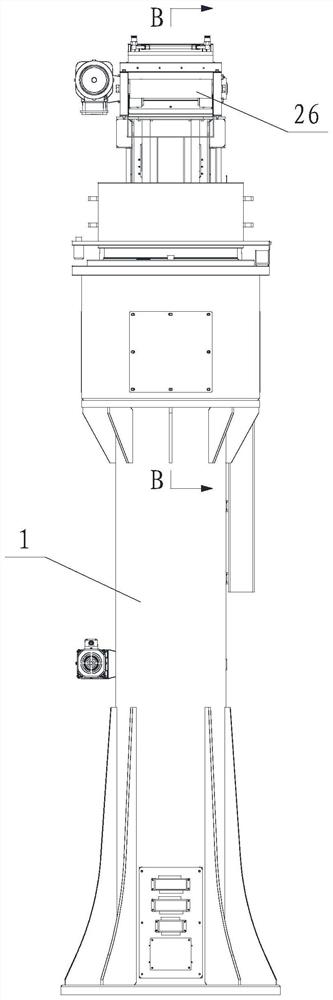

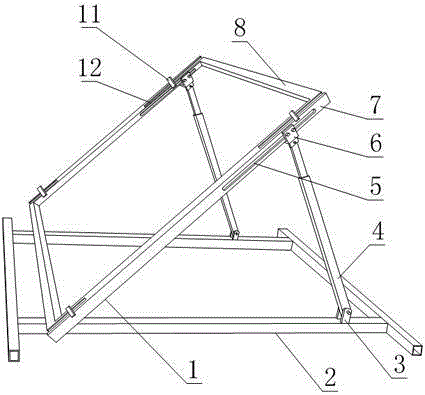

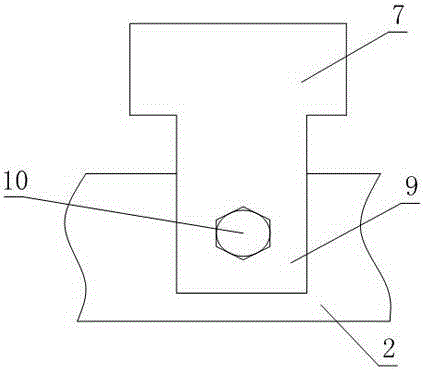

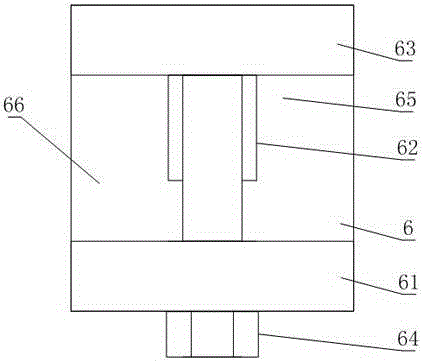

Biomass feed divider with changeable trough obliquity and vibration frequency and amplitude

ActiveCN101613039AContinuous, stable and even distribution of materialsAchieve free rotationLarge containersLoading/unloadingMultiple formsMaterial distribution

The invention relates to a biomass feed divider with changeable trough obliquity and vibration frequency and amplitude, which realizes continuous, stable and safe feed division by adopting two regulating measures of changing obliquity of a trough and changing vibration frequency and amplitude and by exciting force generated by a vibrating motor (9). The device is formed by arranging one or a plurality of independent distributors in parallel, wherein each distributor mainly comprises a trough body (4), a vibrating motor (9), an elevating (8), a spring supporting mechanism (11) and an auxiliary mechanism; the trough body (4) is supported by the spring supporting mechanism (11) at the front part and the elevating (8) at the rear part, the vibrating motor (9) is arranged in the middle of the bottom of the trough body (4), and the rear part of the trough body (4) is connected with bulkhead by canvas (3). The device integrates material storage and material distribution, is not only suitable for hard biomass but also is suitable for soft biomass, and has lateral expansibility, thereby being convenient to be used together with material equipment of various types.

Owner:SOUTHEAST UNIV

Polymer phase-change microsphere and preparation method thereof

InactiveCN101250245AAdjustable sizeStrong acid and alkali resistanceHeat-exchange elementsPhase-change materialEmulsion polymerization

The invention relates to a polymer phase transformation microsphere and a relative preparation method. The preparation method comprises using emulsion polymerization method or suspension polymerization method to synthesize oil absorbing type resin, absorbing organic phase transformation material in the presence of water, coating outer layer, atomizing and drying to obtain the heat capacity microsphere with phase transformation function. The invention has low energy consumption, controllable preparation, various products, better acid and alkali resistance, better heat insulation, better size adaptability, high stability, adjustable grain size of microsphere, high production efficiency, low pollution and simple operation, which is suitable for construction material and paint, with wide application and practical value.

Owner:金小刚

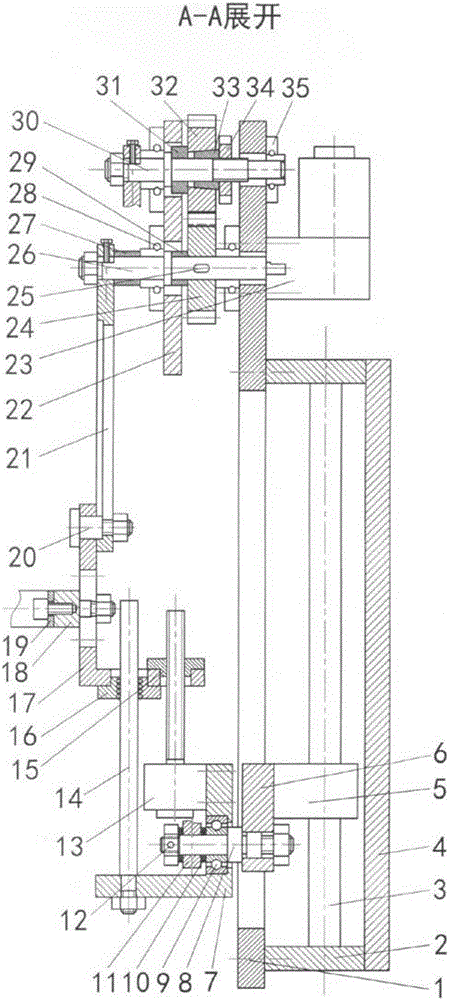

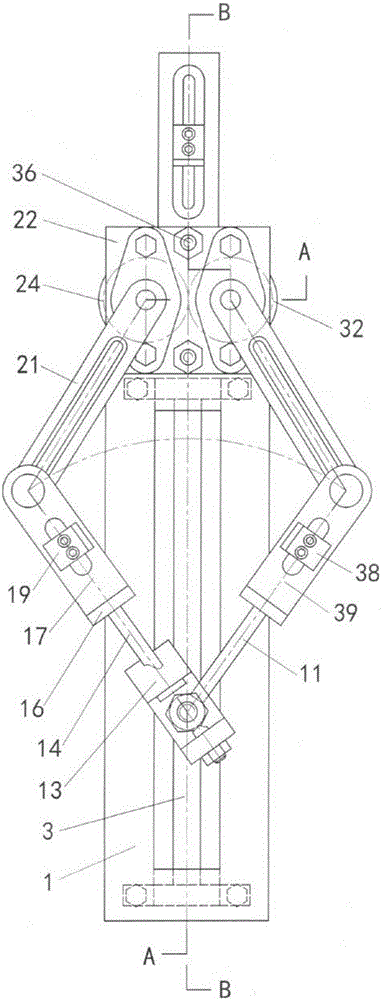

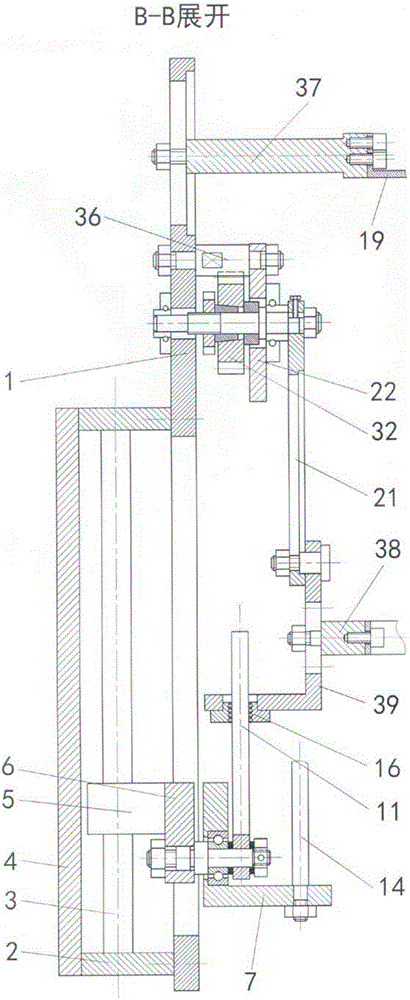

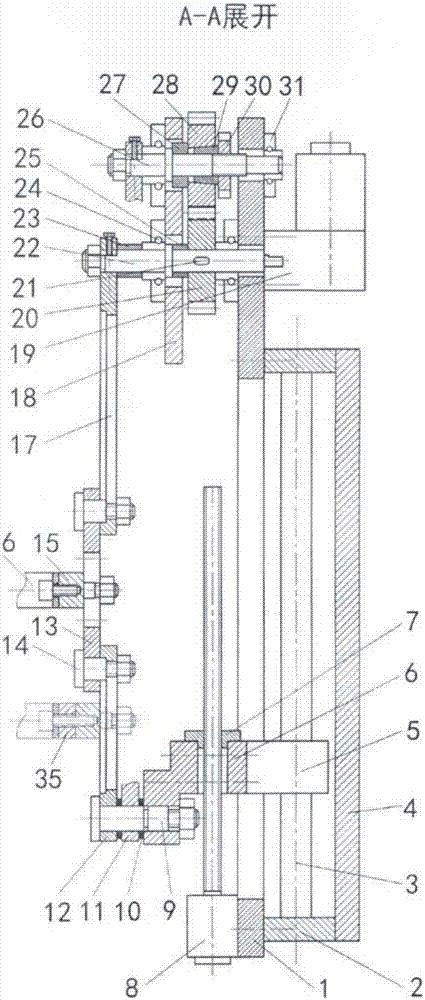

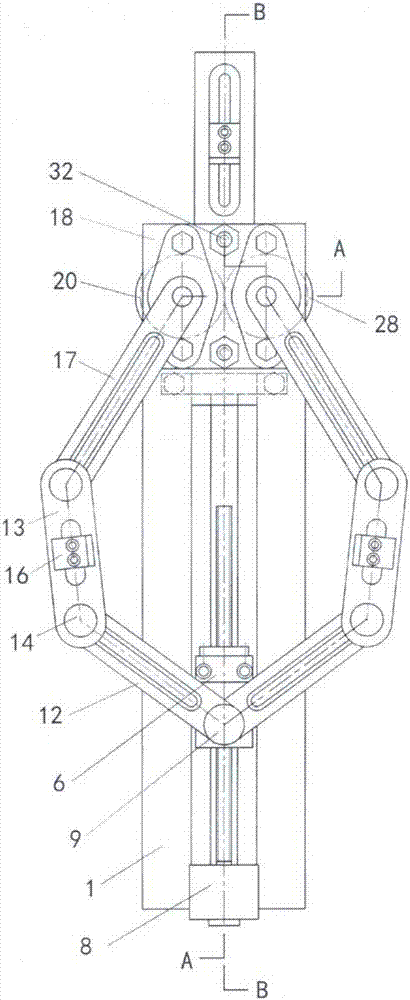

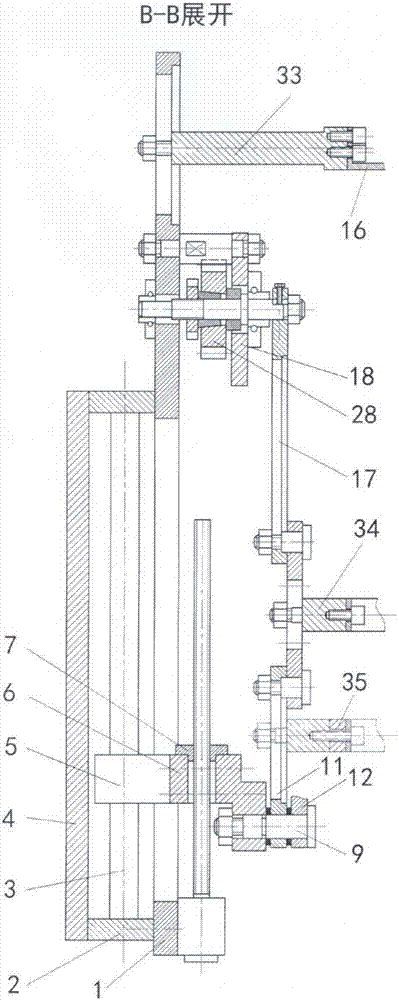

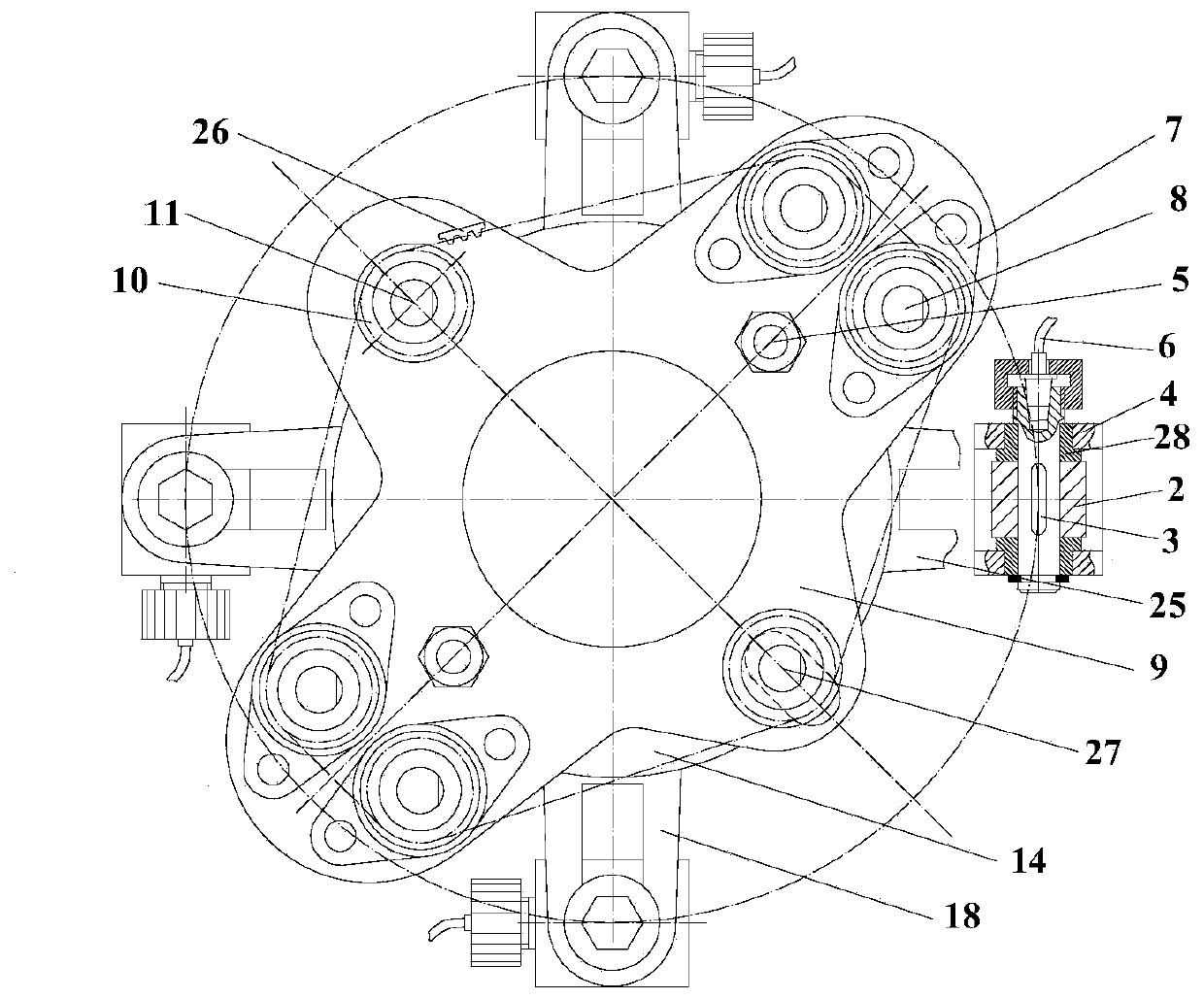

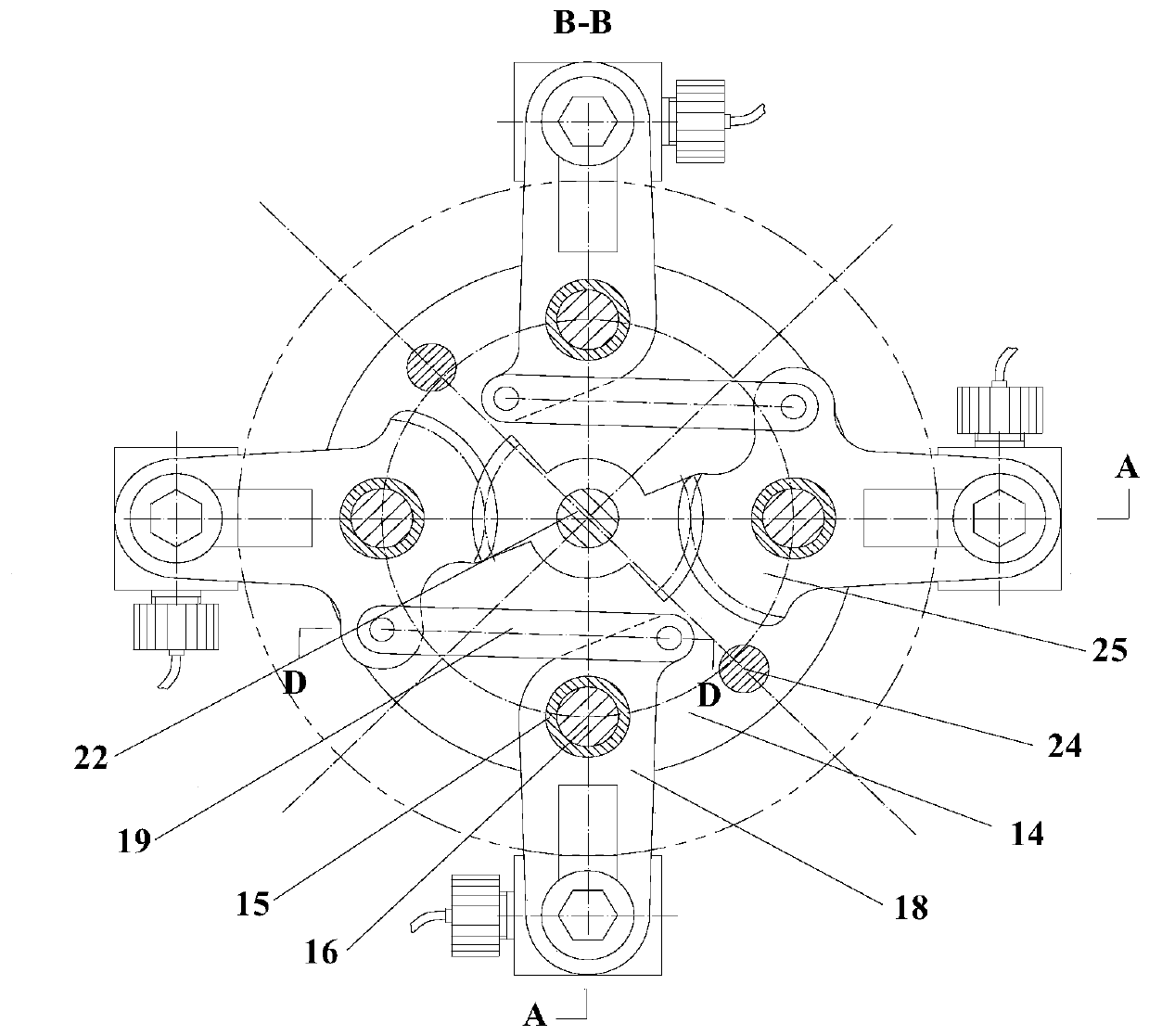

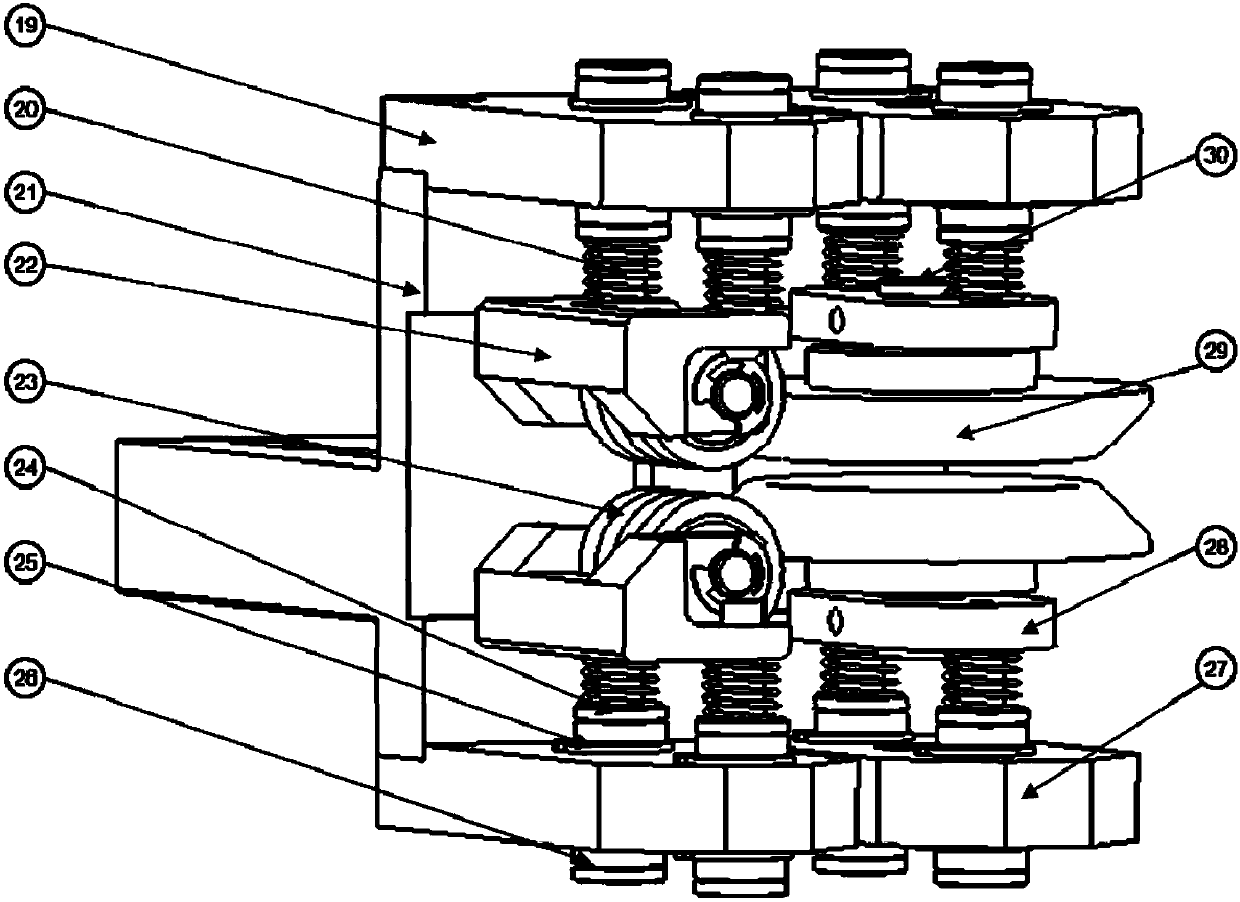

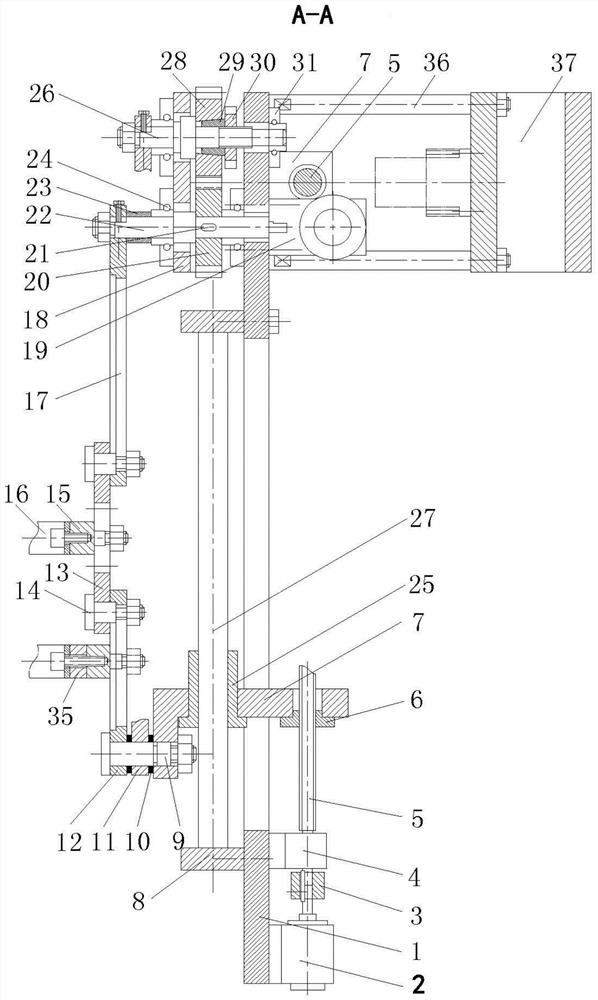

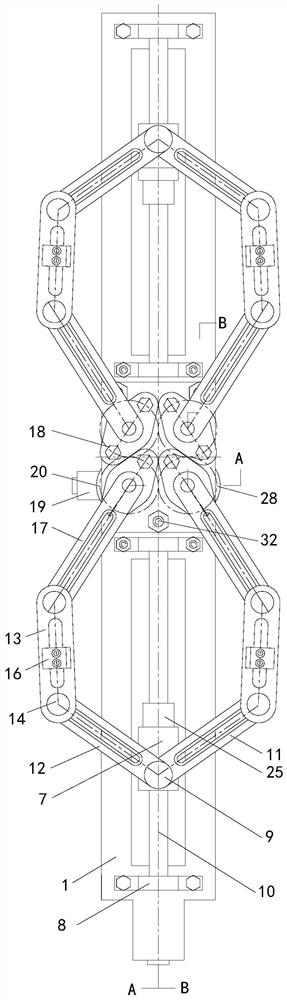

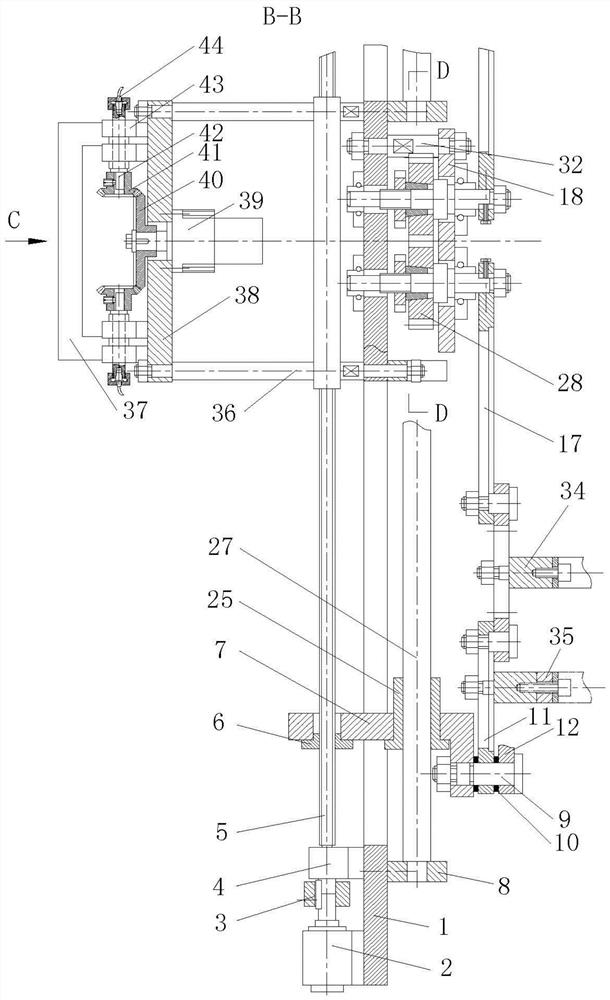

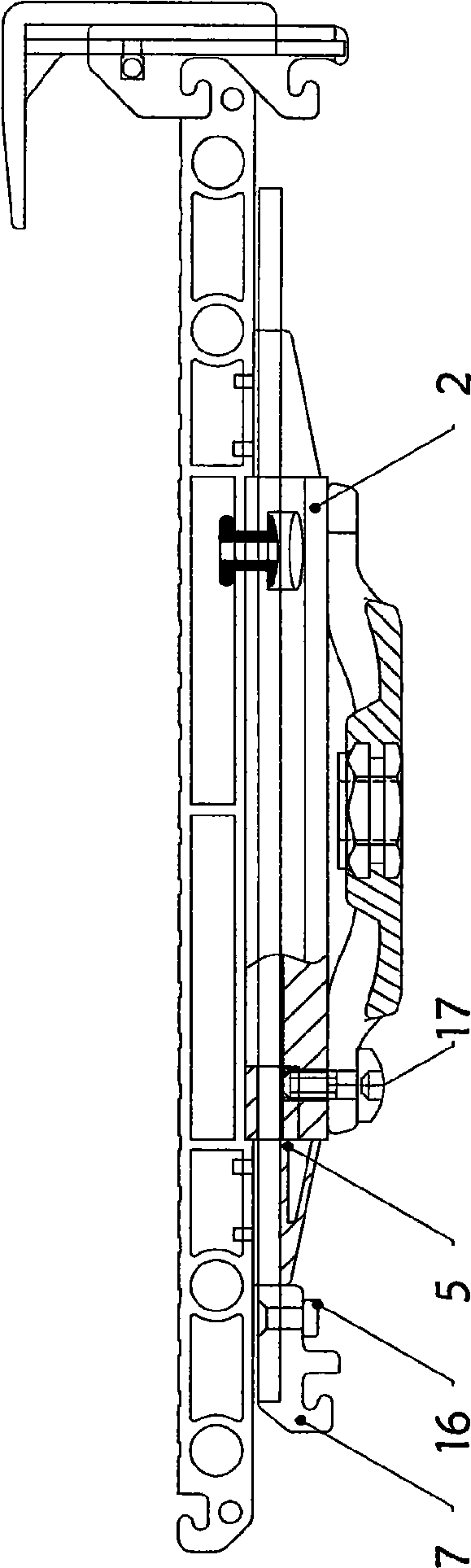

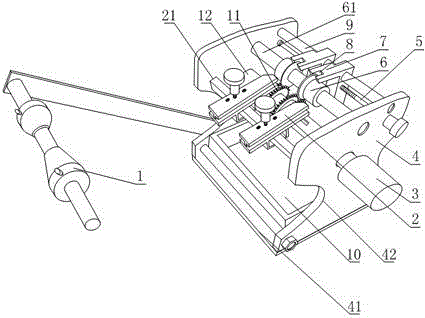

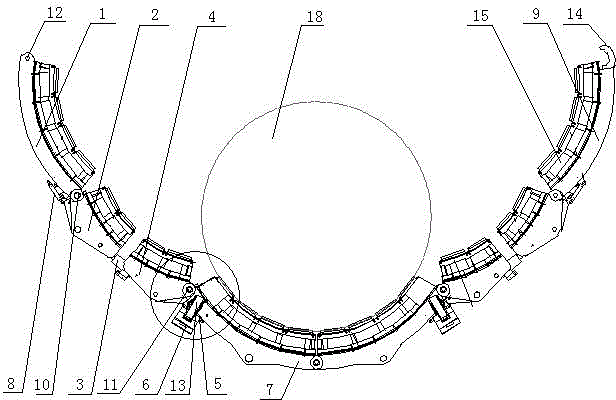

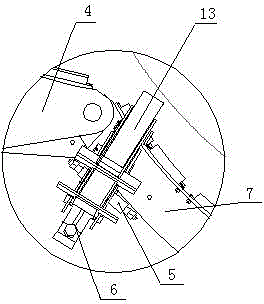

Finger deflection and transposition dual-drive crank slider parallel mechanism palm type mechanical hand

ActiveCN106826798AChange eccentricityImproved size adaptabilityProgramme-controlled manipulatorJointsGear wheelEngineering

The invention discloses a finger deflection and transposition dual-drive crank slider parallel mechanism palm type mechanical hand, and belongs to the field of logistic conveying devices, mechanical hands and robots. A left crank slider mechanism is a driving structure and driven by two stepping motors, crank angular displacement is generated, and the length of a connecting rod is changed; a right crank slider mechanism is a driven mechanism and driven through a pair of gears at constant speed, and the rotating angular displacement of a left crank is the same as that of a right crank; a mechanical hand is provided with three blade spring fingers, and two fingers are installed on connecting rods on the left and right sides and achieve cooperative effect of the two stepping motors; on the basis of manual adjustment, the crank eccentric distance, the positions and angles of the two fingers on the two connecting rods and the position of another fixed finger can be changed; clamping capture power is driven by the two stepping motors, and power outage can be achieved in the grasping process due to the fact that the two stepping motors are locked automatically. The mechanical hand has the advantages of being large in operation space, wide in application range, low in energy consumption and the like.

Owner:JIANGNAN UNIV

Palm type manipulator with dual-drive crank-rocker-slider parallel mechanism capable of changing and rotating positions of fingers

The invention discloses a palm type manipulator with a dual-drive crank-rocker-slider parallel mechanism capable of changing and rotating positions of fingers. Crank-rocker-slider mechanisms are adopted, three identical flexible plate spring fingers are selected, one of the fingers is immobile, and the other two fingers can do translational motion of rotation and movement and are symmetrically mounted on connecting rods or rockers which are positioned on the left and right sides respectively. The crank-rocker-slider mechanism at the left side is an initiatively-driving structure which is driven by two stepping motors respectively to produce angular displacement of cranks and linear translation of sliders; and the crank-rocker-slider mechanism at the right side is a driven structure, transmission is carried out by a pair of gears at constant speed, and rotation angular displacement of the crank at the left side is equal to that of the crank at the right side; by manual adjustment, eccentric distances of the cranks, positions and angles of two fingers which are positioned on the connecting rods or the rockers, and the position of the other fixed finger can be changed. The manipulator disclosed by the invention has the advantages of big operation space, wide adaptability, low energy consumption and the like, and belongs to the fields of logistics conveying equipment, manipulators and robots.

Owner:JIANGNAN UNIV

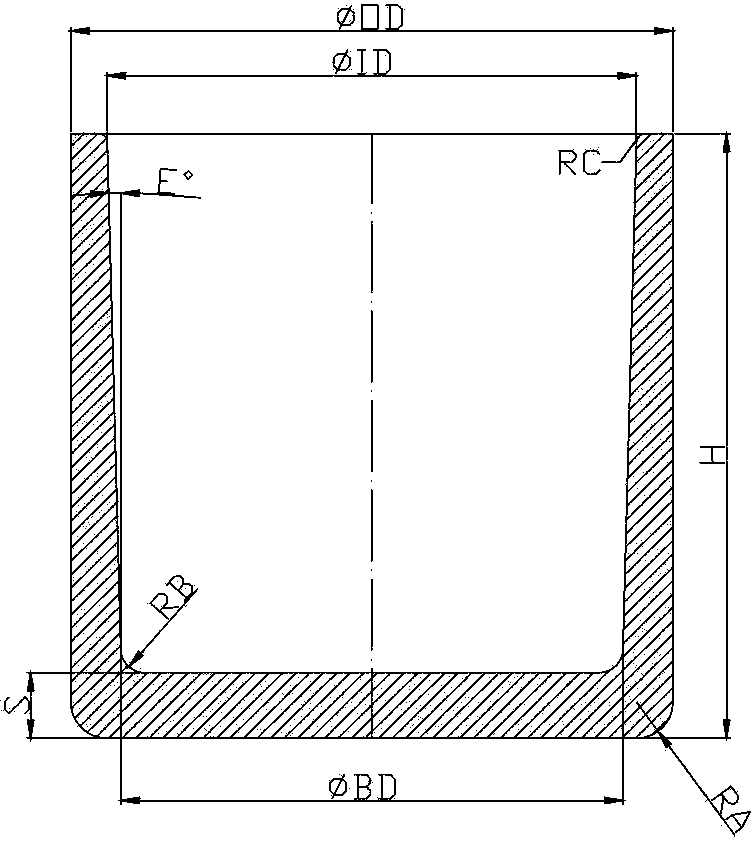

Large-size high-density tungsten crucible and preparation method thereof

The invention provides a large-size high-density tungsten crucible which is mainly used for sapphire crystal growth industry, and particularly provides a preparation method for the large-size high-density tungsten crucible. The method comprises the following steps: raw materials processing, mould core manufacturing, mould setting and forming, high-temperature sintering and mechanical processing. Compared with the prior art, the produced crucible is large in size range and suitable for mass production. Moreover, no binding agent is added in the production process, and impurity content of the product is low; the finished product has the advantages of being high in density, large in size (maximal external diameter of phi 650 mm and maximal height of 800 mm), good in size adaptability and consistency, and high in yield and surface finish, can bear 2000-2300 DEG C high temperature under the protective atmosphere, and can not react with sapphire raw materials under the high temperature.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

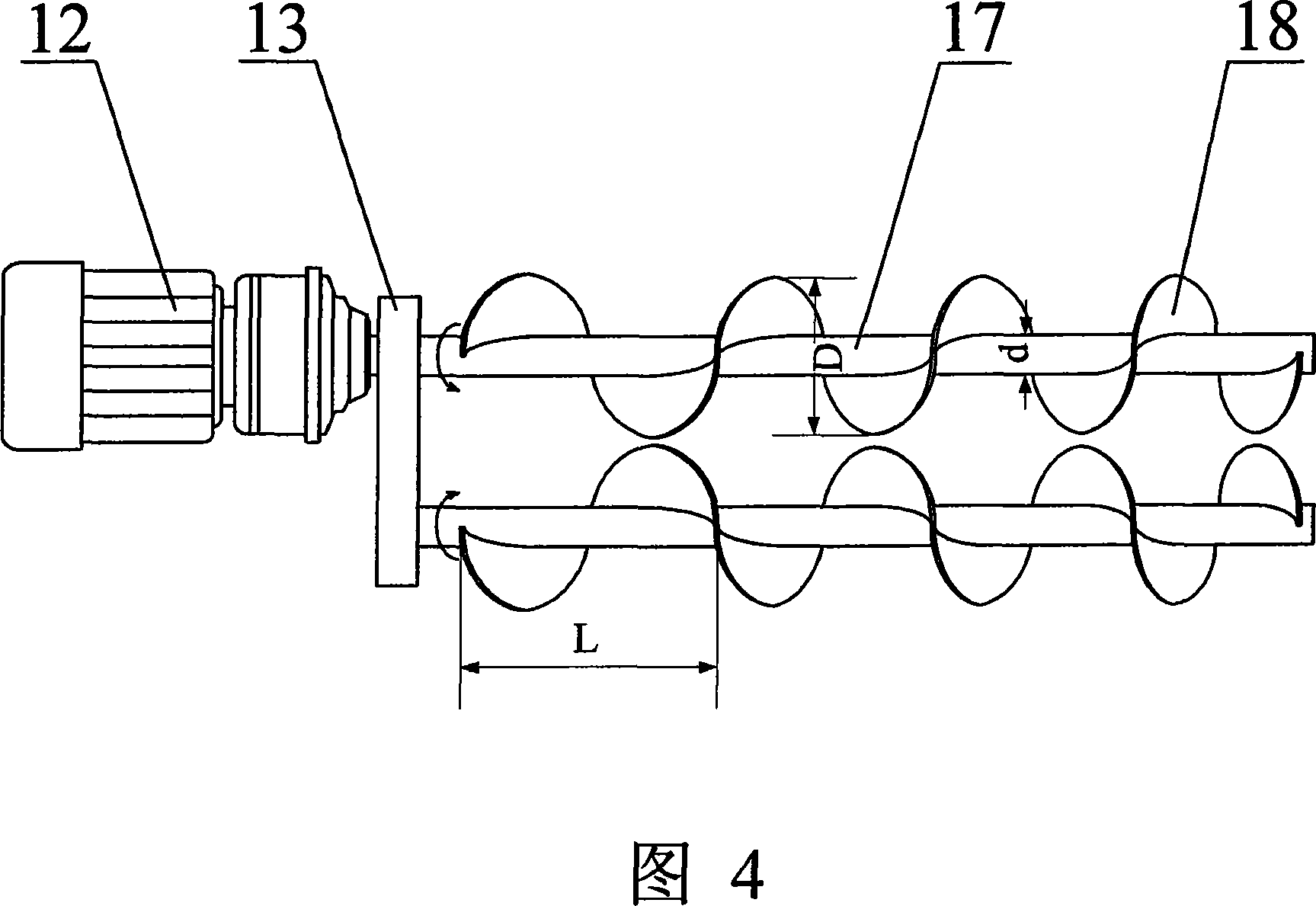

Biological matter straw burning-gasifying feeding apparatus

ActiveCN101025269AContinuous and stable feedingEliminate potential safety hazardsPackagingLump/pulverulent fuel feeder/distributionTransformerAgricultural engineering

The charging device of the straw burning and gasification uses the differential variable-pitch double helix to reach the charging continuously especially for the strip biological fuel. The device includes: material barn, the feeding helix, the middle hopper, the dehvery helix; the material barn is on the top which the upper mouth is connected with the upper side of the feeding helix middle which the material drop mouth is connected to the upper mouth of the middle hopper which the low mouth is connected to the upper side of the dehvery helix. The device transfers the straw of 10-200mm into the material barn by the double helix feeder, then it drops into the middle hopper, next the double helix transformer at the bottom of the hopper transfers the straw into the burning and gasification device.

Owner:SOUTHEAST UNIV

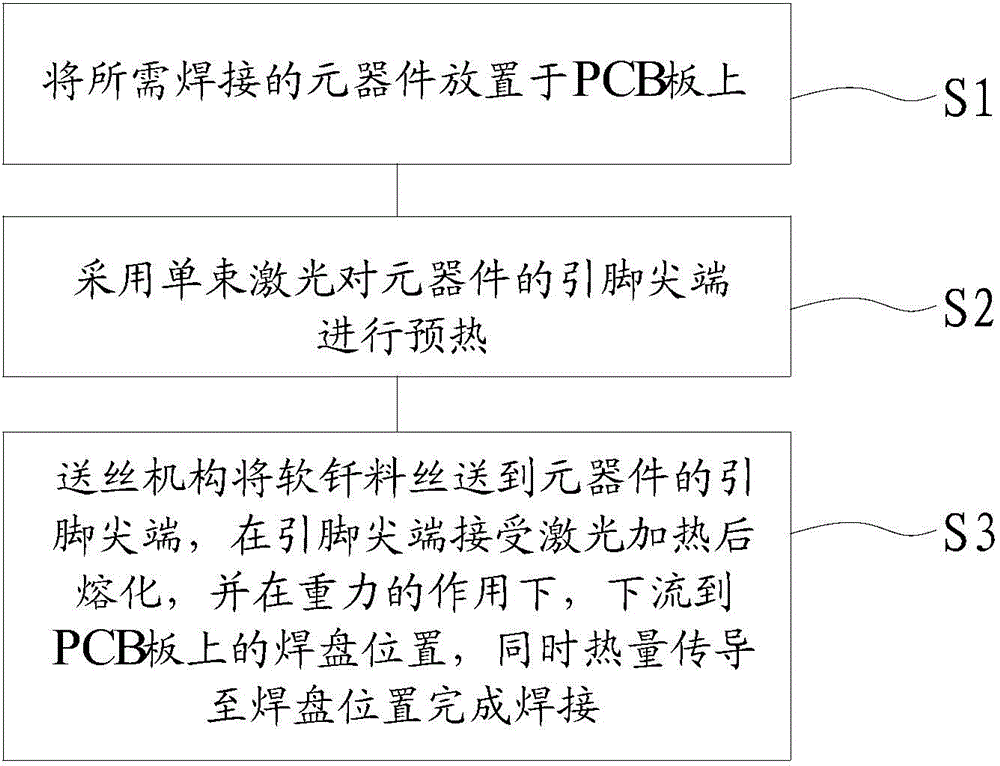

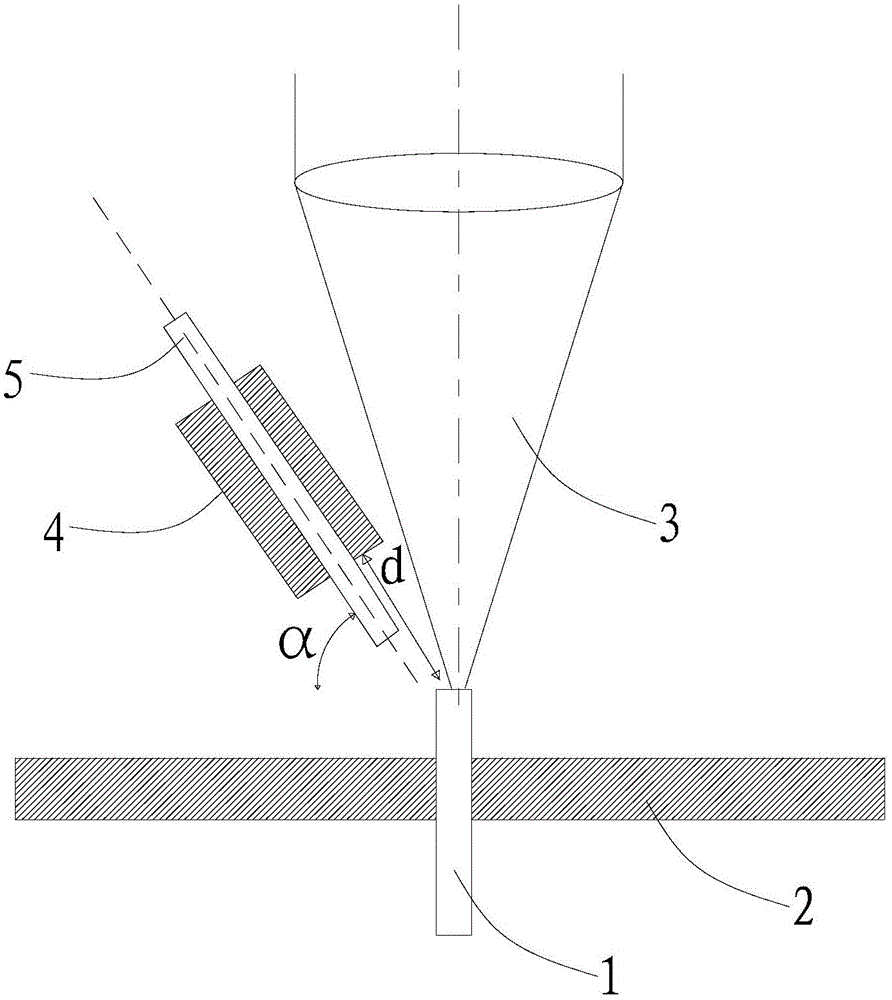

Method for welding component pin and apparatus thereof

ActiveCN104923914AShort warm-up timeEasy to debugPrinted circuit assemblingMetal working apparatusHeating timeEngineering

The invention relates to the field of welding technology, and discloses a method for welding a pin of a component and an apparatus thereof. The method herein comprises welding the component pin to a PCB board by using laser and a wire feeder, wherein the laser refers to a single beam laser. During welding, the laser supplies heat to the tip end of the component pin, and the wire feeder delivers the wire to the tip end of the component pin. According to the invention, the laser supplies heat to the tip end of the component pin instead of a coated copper layer on the PCB board, and the wire feeder delivers the wire to the tip end of the component pin instead of the coated copper layer on the PCB board. Thus, the method herein is applicable to welding pins of all plug-in types of components with no concerns of the morphology of the cross section or the size of the cross section area, or factors like heat radiation property of the coated copper layer. The method herein has the advantages of short pre-heating time, simple modulation, and a wide range of application.

Owner:HANS LASER TECH IND GRP CO LTD

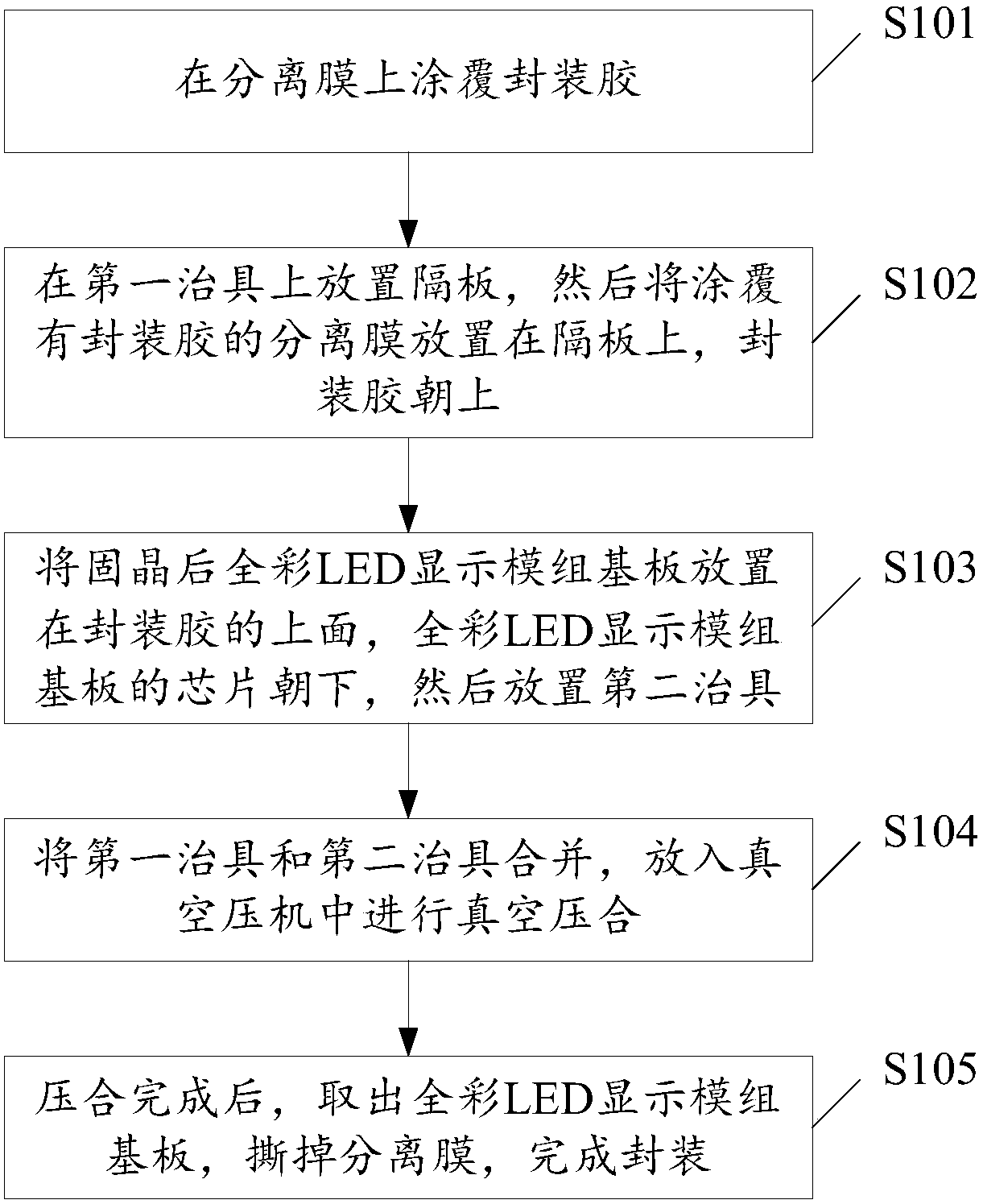

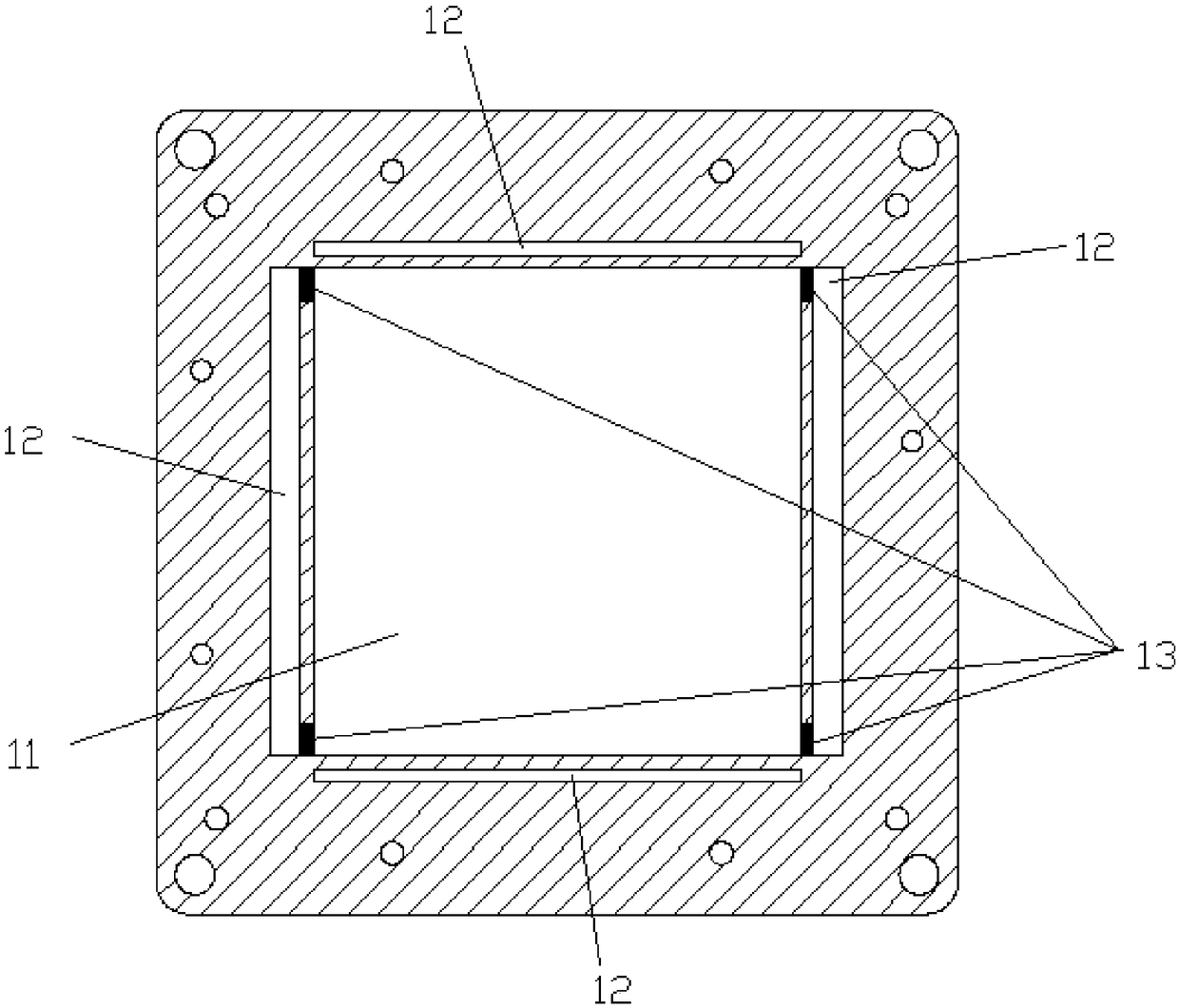

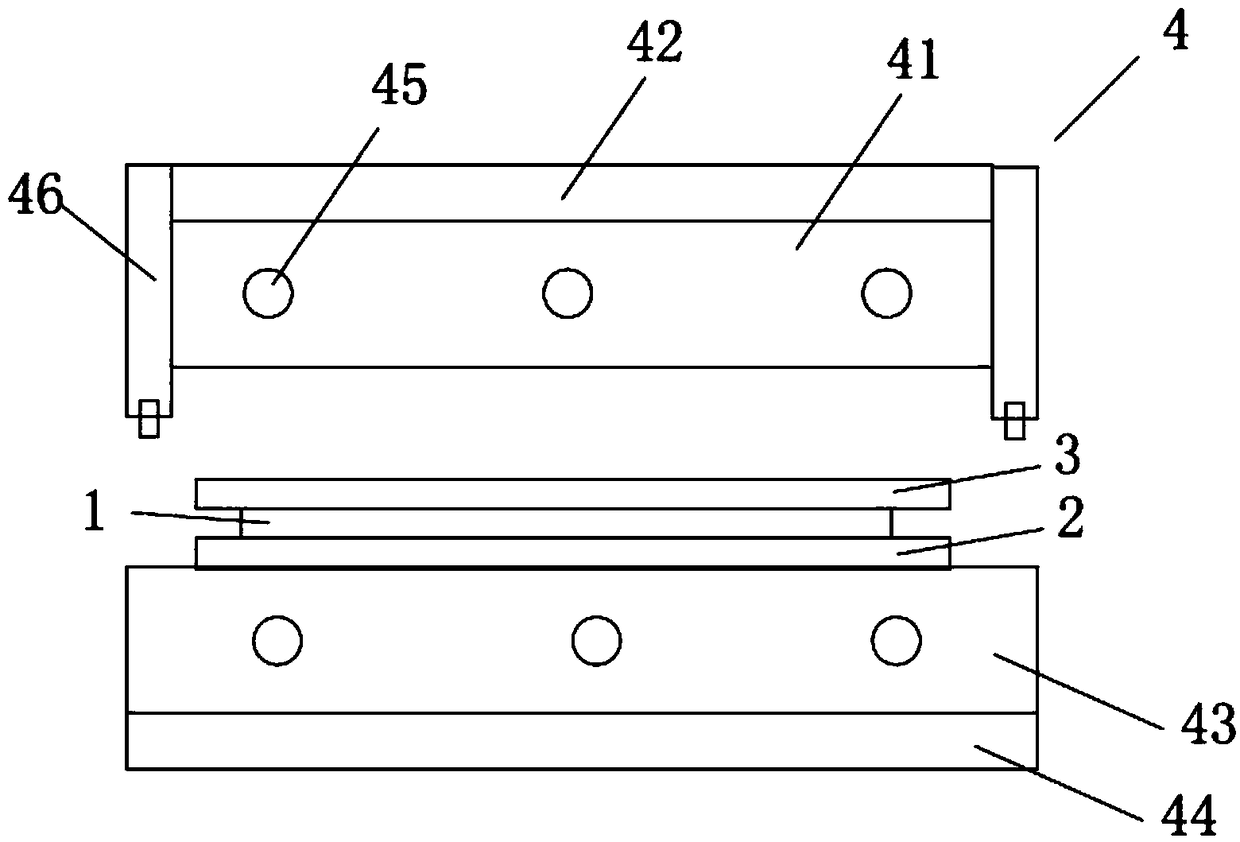

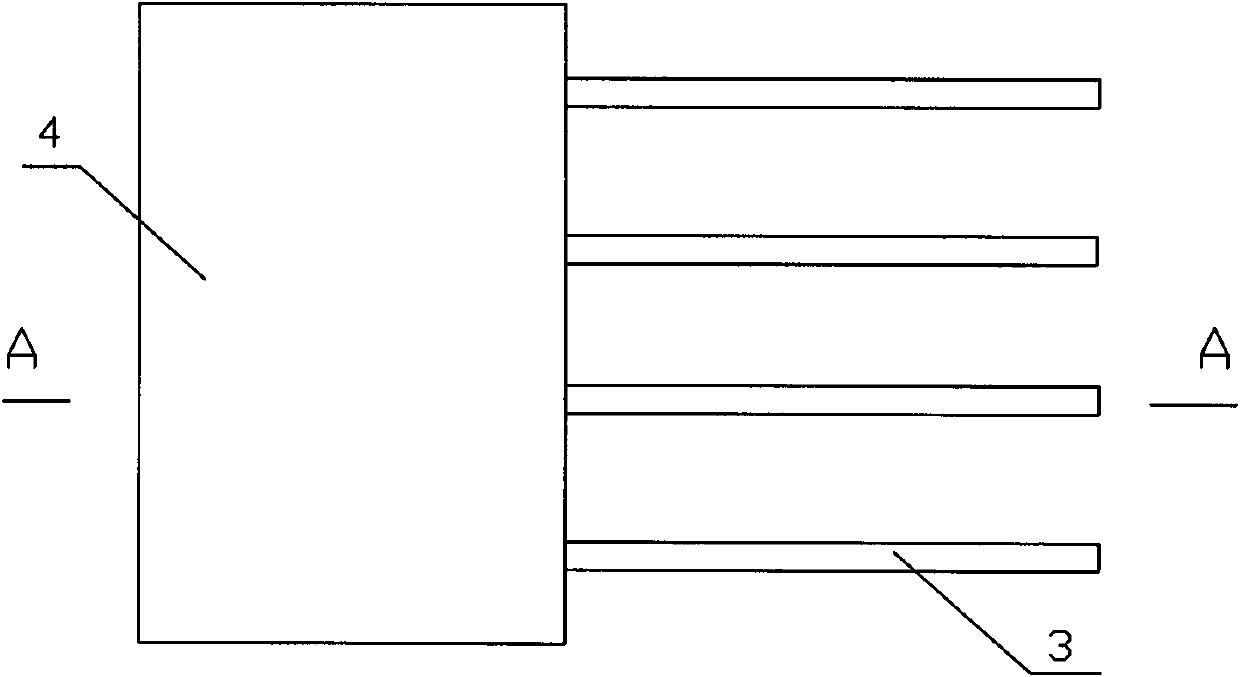

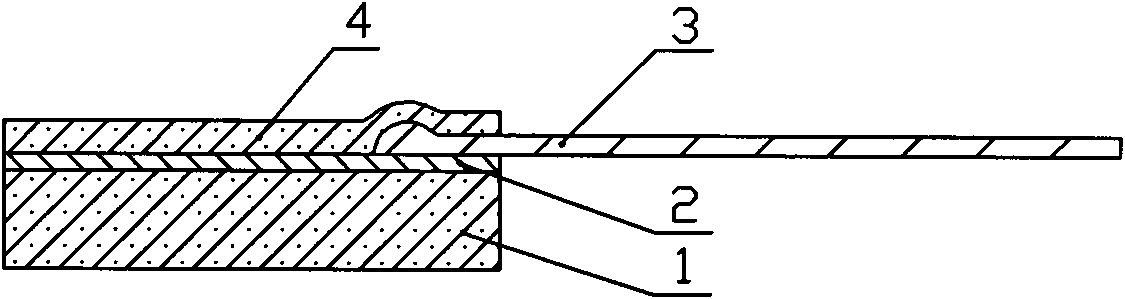

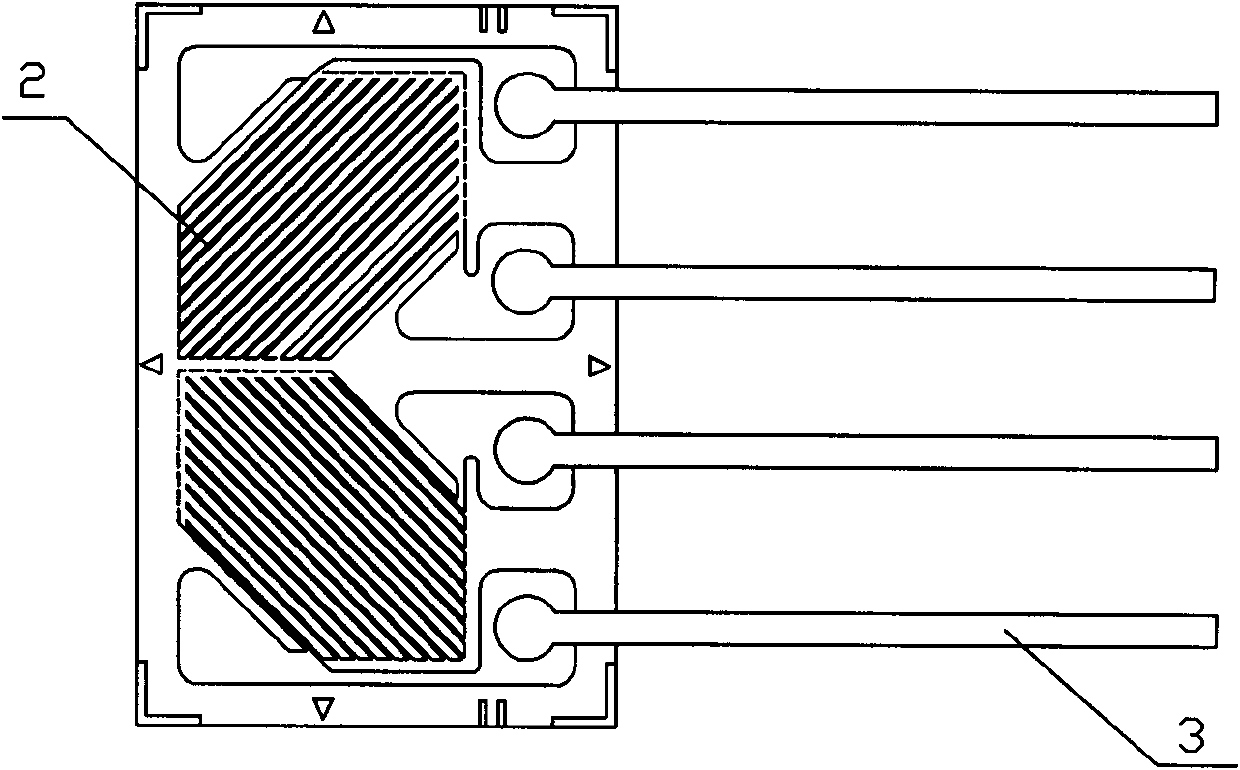

Full-color LED display module, packaging method and display screen of full-color LED display module

InactiveCN108448012ATo achieve a variety of choicesImproved size adaptabilitySolid-state devicesSemiconductor/solid-state device manufacturingLED displayEngineering

The invention discloses a packaging method of a full-color LED display module. The method comprises the steps of 1, coating the package resin on a separation film; 2, placing a separation plate on a first jig, and placing the separation film coated with the package resin on the separation plate, wherein the side of the separation film with the package resin is placed upwards; 3, placing the solid-crystal full-color LED display module substrate on the package resin, placing the chip of a full-color LED display module substrate to be downwards, and then placing a second jig; 4, combining the first jig and the second jig, and putting the first jig and the second jig into a vacuum air compressor for vacuum lamination; 5, after the lamination is completed, taking out the full-color LED displaymodule substrate, tearing off the separation film, and finishing the packaging operation. Correspondingly, the invention further provides a full-color LED display module and a display screen of the full-color LED display module. By the adoption of the method, the diversified selection of packaging sizes and packaging materials can be realized. The packaging quality is good, and the foaming is avoided. The requirement on packaging equipment is low.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

Medium-temperature foil type resistance strain gauge

ActiveCN102636106AImprove anti-agingImprove antioxidant capacityElectrical/magnetic solid deformation measurementSelf compensationOxidation resistant

The invention discloses a medium-temperature foil type resistance strain gauge. The medium-temperature foil type resistance strain gauge comprises a substrate, a sensitive grid and a sealing layer, wherein the sensitive grid is firmly adhered to the substrate and is sealed by the sealing layer; the substrate is made of an enhanced polyimide composite material or an enhanced organic silicon resin composite material; the sensitive grid is made of a Karma alloy, an Even alloy or a nickel-chromium alloy; and the sealing layer is made of polyimide or an organic silicon resin material. The medium-temperature foil type resistance strain gauge improves the stress-strain measurement accuracy in a medium-temperature environment, and the average heat output coefficient of the strain gauge is controlled in a range of 2 mu epsilon / DEG C; in the medium-temperature environment, the strain gauge has stable properties such as relative sensitivity coefficient, creep deformation and the like, can stably measure signals, and has the functions of creep deformation self-compensation and elasticity modulus self-compensation; the aging resistance and oxidation resistance of the materials of the substrate and sealing layer of the strain gauge are improved in the medium-temperature environment; and the adaptive temperature range can be expanded to be between -30 and 400 DEG C, and the consistency of the measurement accuracy is good.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

Quick-changing finger change-palm mechanical arm with finger root soft shafts delivering rotation and performing eccentric transposition

ActiveCN111360865AReasonable structural designEasy to controlGripping headsElectric machineryAgricultural engineering

The invention relates to a quick-changing finger change-palm mechanical arm with finger root soft shafts delivering rotation and performing eccentric transposition, relates to the field of robots andautomation and is suitable for the field of food, light industry and agricultural product sorting robots and packaging and logistics industry robots. The quick-changing finger change-palm mechanical arm is composed of a palm component and four fingers of the same structure, wherein a palm provides a transposition function of finger root components, and the four fingers grab upright cylinders, spheres and cubes or the left and right fingers perform clockwise transposition by 45 degrees and the front and rear fingers perform anticlockwise transposition by 45 degrees under driving of a motor forthe four fingers grabbing horizontal cylinders and cuboids; the palm provides a rotating function of the finger root components, a rotating driver is provided with two kinds of the motor and a vane-type rotating air cylinder and drives a toothed belt and makes the four fingers rotate at the same finger root angle through four soft shafts, and the finger root angle is an included angle between thefinger root components and a palm plane; and the fingers are provided with four kinds of an unactuated rotating clamping finger, a translational clamping finger, a pneumatic knuckle envelope finger and a soft body wrapping finger.

Owner:JIANGNAN UNIV

Flexible edge sealing mechanism for automatic edge sealing machine of solar dual-glass battery module

PendingCN107591462AEasy to operateQuality assuranceFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention relates to a flexible edge sealing mechanism for an automatic edge sealing machine of a solar dual-glass battery module. The flexible edge sealing mechanism for the automatic edge sealing machine of the solar dual-glass battery module comprises a moving adjustment mechanism and a flexible edge sealing mechanism substrate, wherein the flexible edge sealing mechanism substrate is connected with the moving adjustment mechanism, a flexible mechanism installation plate is arranged at a left segment of the flexible edge sealing mechanism substrate, a glass guide mechanism is arranged at a position, near to a front part, of an intermediate segment, an adhesive tape guide positioning mechanism is arranged at a position, near to a rear part, of the intermediate segment, an adhesive tape loading mechanism is arranged at a right segment, and a flexible adhesive tape formation mechanism and a flexible adhesive tape kneading mechanism are sequentially arranged on the flexible mechanism installation plate from left to right. The flexible edge sealing mechanism for the automatic edge sealing machine of the solar dual-glass battery module is simple and convenient to operate, the sizeof a force applied to the dual-glass assembly is flexibly adjusted, the adhesive tape attachment quality is ensured, the adhesive tape attachment accuracy is high, the attachment appearance is attractive, and the adaptability to the glass size is high.

Owner:SUZHOU IND ROBOT TECH

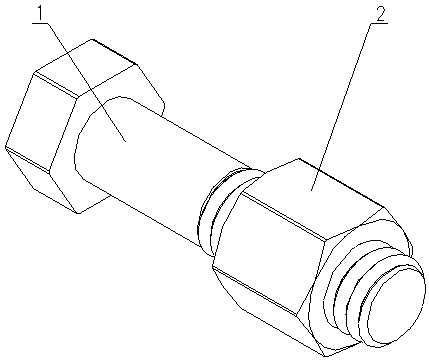

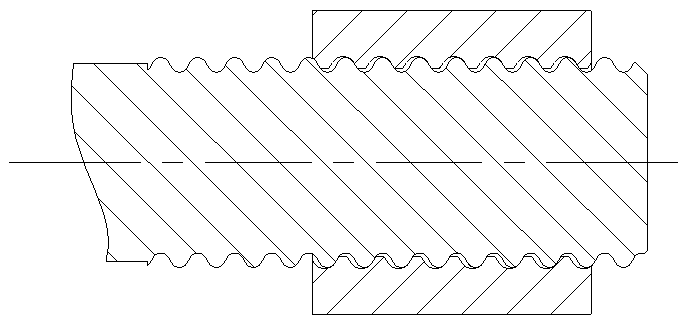

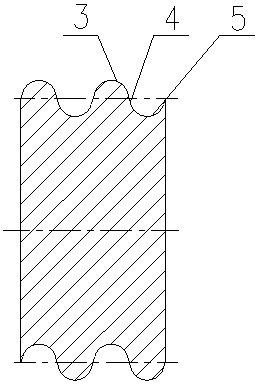

High-strength arc thread connection pair

PendingCN109958698AReduce stress concentrationEven by forceNutsBoltsStress concentrationHigh intensity

The invention discloses a high-strength arc thread connection pair. A bolt and a nut are provided with an internal arc thread and an external arc thread which are matched with each other, the internalarc thread and the external arc thread are connection threads with surface contact, a continuous arc thread on the bolt is an external thread, the external thread is composed of an upper crest arc, astraight line segment, a lower root arc and a straight line segment which are successively connected, the radius of the upper crest arc is the same as that of the lower root arc, and the straight line segments are tangent to the upper crest arc and the lower root arc correspondingly; and a continuous circular thread on the nut is an internal thread, the internal thread is composed of an upper half-round arc, a tangential straight line segment and a crest which are successively connected, the crest is a plane, the tangential straight line segment is tangent to the upper half-round arc. The arcthread connection pair adopts an arc thread form, the internal thread makes a surface contact with the external thread, stress is uniform, stress concentration during thread bearing can be effectively lowered, and the anti-fatigue performance is good.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

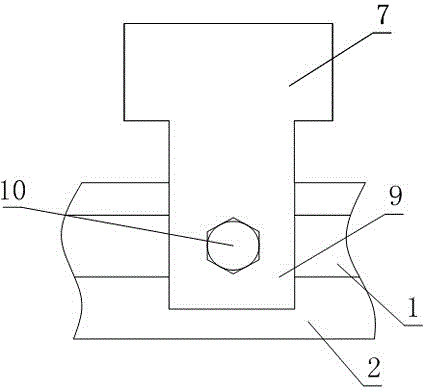

Photovoltaic plate installing rack convenient to install

InactiveCN105024634AExpand the adjustment rangeLarge adjustment rangePhotovoltaic supportsPhotovoltaic energy generationFixed frameSlide plate

The invention discloses a photovoltaic plate installing rack convenient to install. The photovoltaic plate comprises a fixing frame and a photovoltaic plate fixing plate. The photovoltaic plate fixing plate is further fixedly provided with a plurality of buckles. The fixing frame is provided with strip-shaped base plate sliding grooves. The lower end of the photovoltaic plate fixing plate is fixedly connected with locking plates. Each locking plate is provided with a bolt hole. The bolt hole is provided with a locking bolt. The fixing frame is further provided with hinge blocks and adjusting rods. The hinge blocks are hinged with the lower ends of the adjusting rods. The upper ends of the adjusting rods are hinged with sliding plates. The sliding plates are fixedly connected to the photovoltaic plate fixing plate. The buckles comprise pressing plates, fastening sliding blocks and compressing bolts. The photovoltaic plate fixing plate further comprises adjusting grooves. The photovoltaic plate installing rack is simple in structure, and the angle adjustment of a photovoltaic plate relative to a horizontal plane can be realized conveniently; in addition, the photovoltaic plate installing rack depends little on the landform, is convenient to transport and has a good adaptation capability to the size of the photovoltaic plate.

Owner:SICHUAN LANXUNBAOER ELECTRONICS TECH

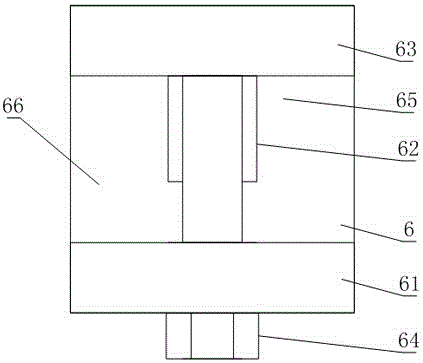

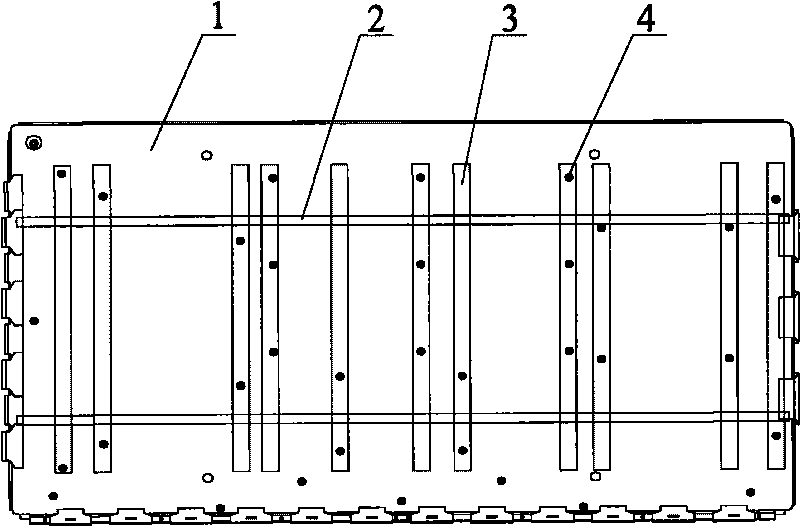

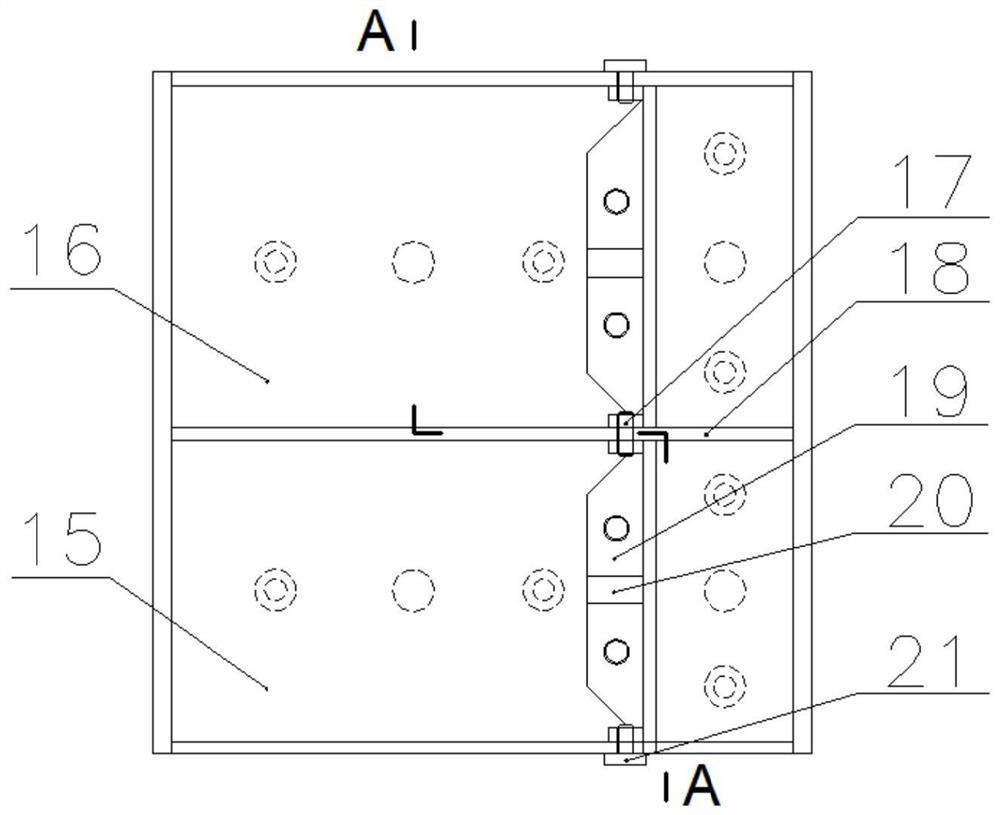

Back plate for plasma display

InactiveCN101728161AImproved size adaptabilitySolve the problem of poor size adaptabilitySolid cathode detailsPlasma displayComputer engineering

The invention provides a back plate for a plasma display, comprising a guide rail which is fixed on the back plate transversely; a sliding rail which is arranged on the guide rail longitudinally and moves laterally along the guide rail; and a double-screw bolt which is arranged on the sliding rail; the back plate can fix PCB with different sizes, the position of the double-screw bolt on the back plate can be adjusted continuously, so as to improve the adaptability of the back plate to the size of the PCB and realize the compatible performance of the display screen with the same specification to PCB with different sizes.

Owner:SICHUAN COC DISPLAY DEVICES

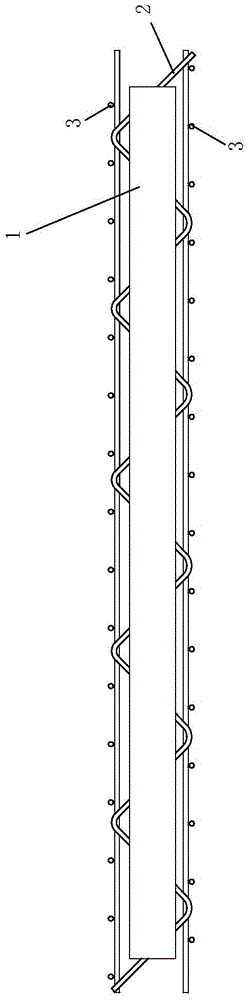

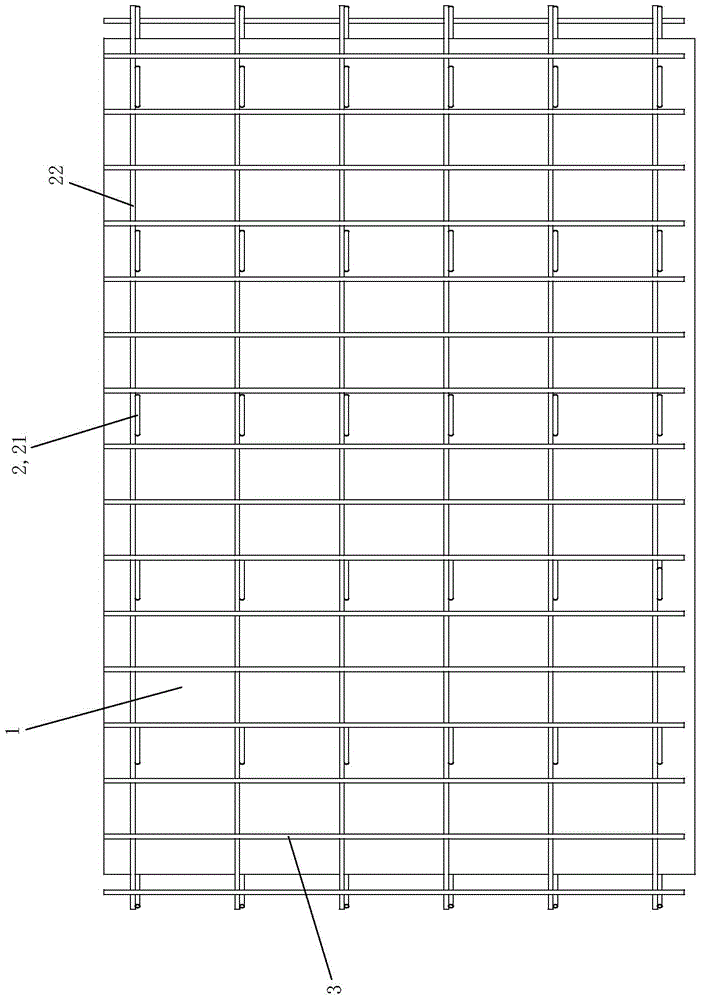

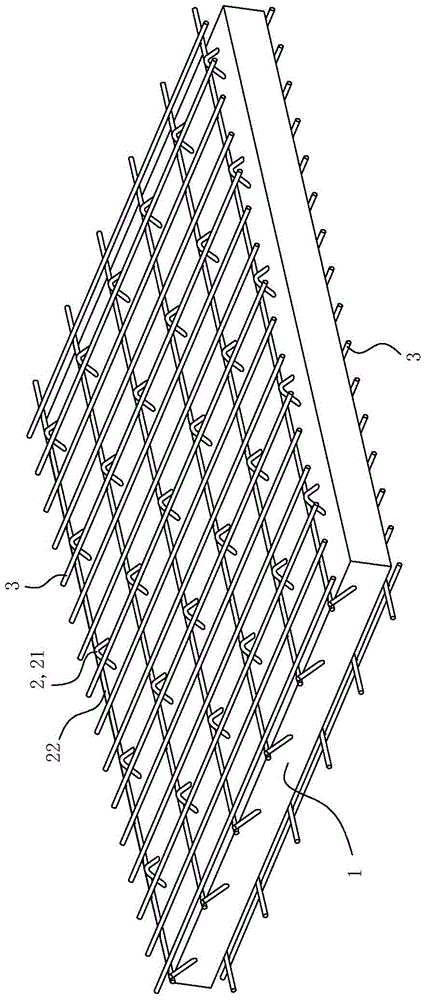

External wall insulation board and manufacturing method thereof

InactiveCN104264845BSimple structureHigh tensile strengthCeramic shaping apparatusHeat proofingHorizontal barExternal wall insulation

The invention discloses a thermal insulation board for an outer wall, which is characterized in that it comprises a thermal insulation piece, a truss and a transverse bar. The insulation part is perlite insulation board or cement foam insulation board. There is one group of trusses, each truss has the same structure, each truss is arranged parallel to each other, and is vertically arranged along the length direction of the thermal insulation part. The thermal insulation parts are pressed on each truss, and the upper and lower ribs of each truss are located outside the thermal insulation parts. There are several transverse ribs, and each transverse rib is arranged parallel to each other, and is all arranged along the width direction of the thermal insulation part. Each transverse rib is welded and fixed on the upper and lower ribs of each corresponding truss at intervals.

Owner:CHANGZHOU WULIU YIGU INTELLIGENT EQUIP

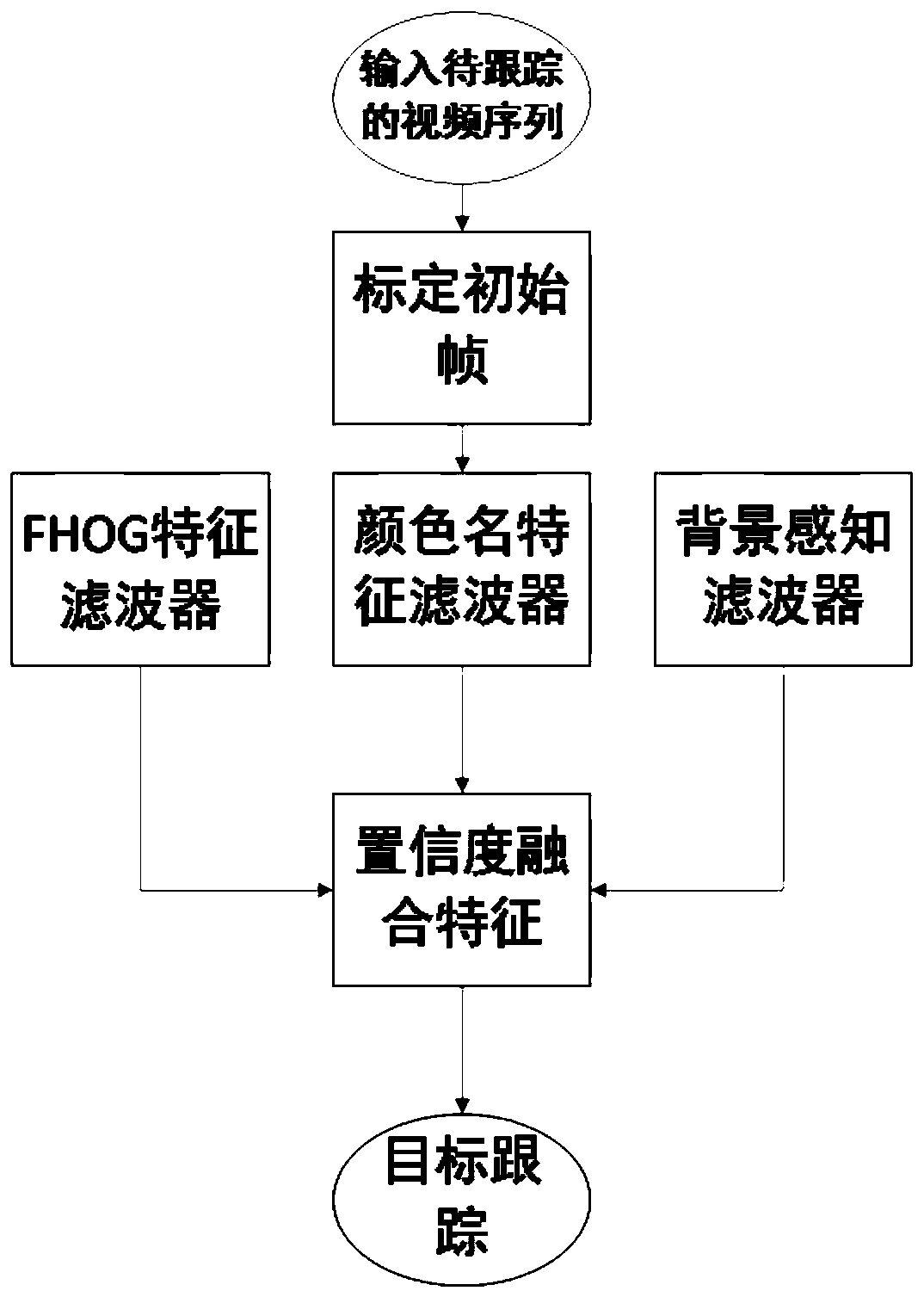

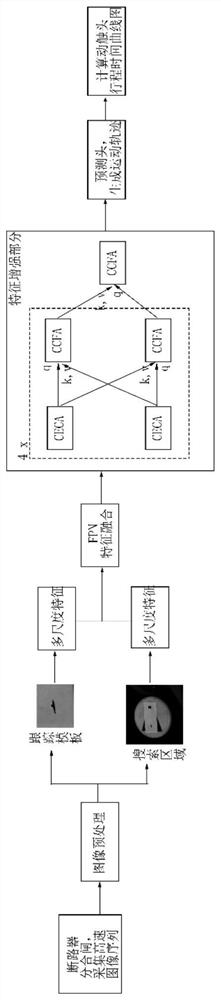

Confidence term filter target tracking method for enhancing multi-feature fusion

ActiveCN111145121AGood tracking effectEnhance expressive abilityImage enhancementImage analysisPattern recognitionMulti feature fusion

The invention discloses a confidence term filter target tracking method for enhancing multi-feature fusion, and belongs to the technical field of target tracking. The target tracking method comprisesthe following steps: carrying out calibration processing on internal and external parameters of a camera; obtaining an input object of a target, inputting a to-be-tracked video sequence, and marking an initial frame; filming the video information of the tracked target object in the monitoring area in real time by using a camera, and transmitting the video information to a video data processing unit; introducing an FHOG characteristic filter, a color name characteristic filter and a background perception filter; and according to the maximum response peak value and the average peak related energy of the filter, adding linear fusion of the adaptive multi-feature response filter to obtain a fusion confidence feature. According to the invention, the aliasing effect problem of the filter model can be effectively solved, and compared with a traditional algorithm, the algorithm has better robustness.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

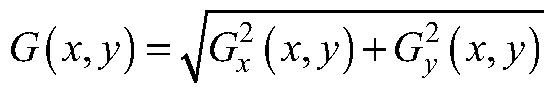

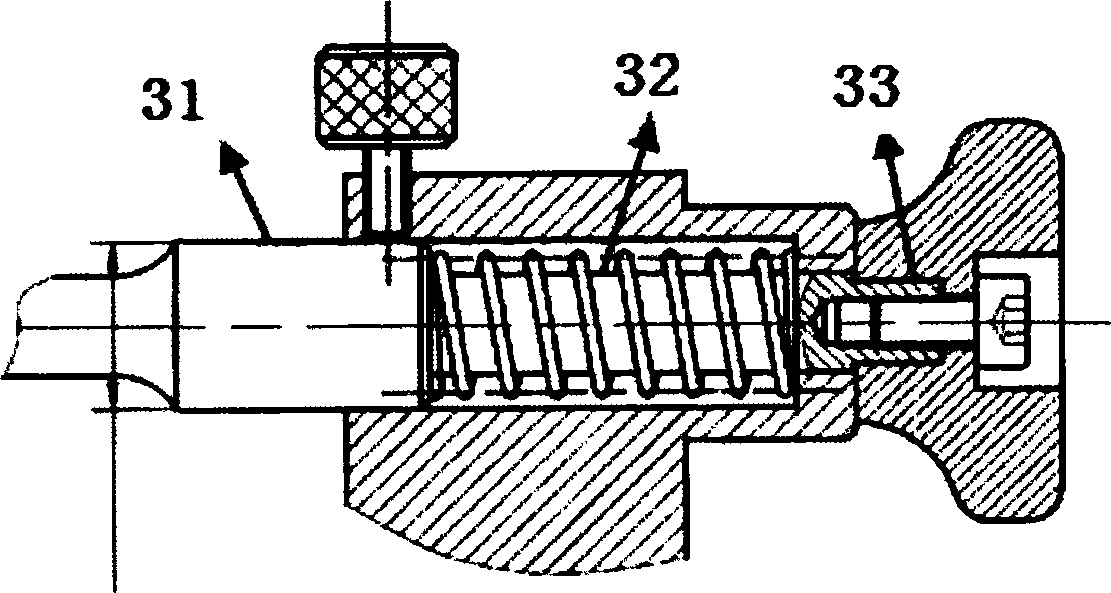

Low-loss material dielectric property measurement device adopting split-cylinder resonator method

ActiveCN104297572APrecise alignmentSmooth motionResistance/reactance/impedenceResonant cavityElectricity

The invention provides a low-loss material dielectric property measurement device adopting a split-cylinder resonator method. The low-loss material dielectric property measurement device adopting the split-cylinder resonator method comprises a base plate, a fixed cavity, a movable cavity, a supporting seat, a force moment handle, a lower guide rod, a precise linear bearing, an upper guide rod, a locking screw, a coaxial connector, a positioning pin, a connecting plate, a protective plate and a stop block. By means of the scheme, the theoretical advantage that the accuracy of low-loss material dielectric property measurement by means of the split-cylinder resonator method is high can be fully played. In addition, measured samples are simple in preparation and quick and convenient to measure. For different measured samples, clamping forces of two resonant cavities can be adjusted through the force moment handle, accordingly measurement distortion caused by improper clamping is decreased, and measurement accuracy is ensured. For the same samples, the clamping forces are constant, and consistency of measurement results can be ensured.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

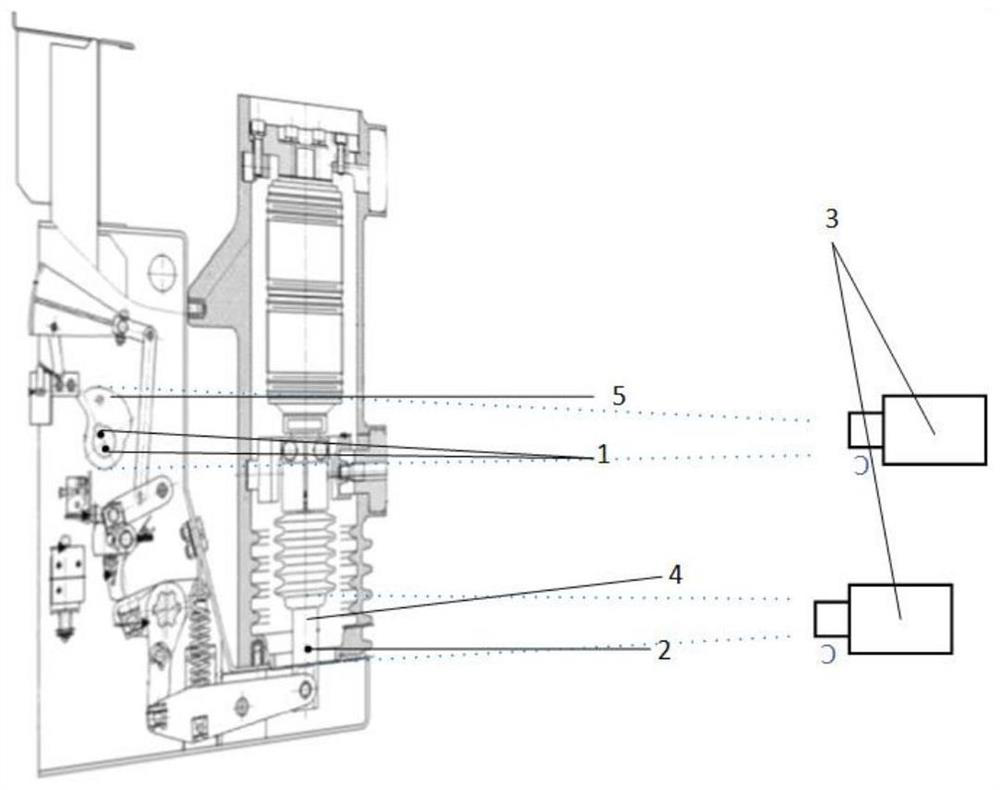

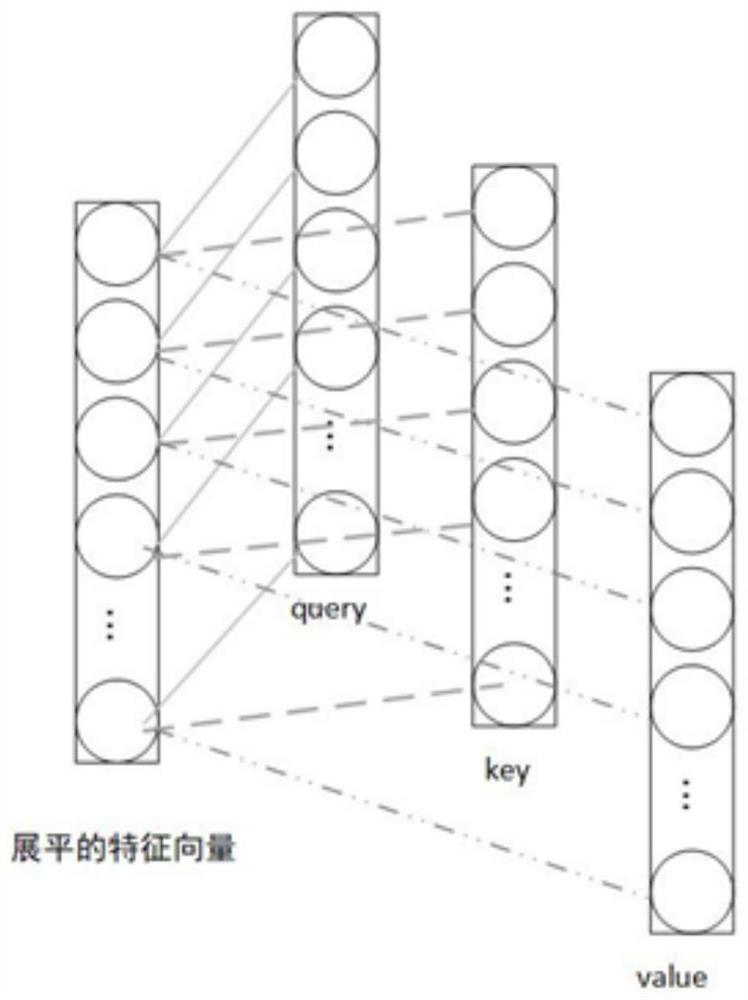

Method for measuring motion characteristics of moving contact of circuit breaker based on deep learning

PendingCN114693741AIncrease the number ofCopes effectively with sizeImage enhancementImage analysisEngineeringCircuit breaker

The invention discloses a circuit breaker moving contact motion characteristic measurement method based on deep learning, and the method specifically comprises the following steps: S1, setting an auxiliary marker, and collecting a high-speed image sequence; s2, inputting the high-speed image sequence into the trained deep learning model, and tracking the motion trail of the auxiliary marker; and S3, calculating the travel time curve of the moving contact of the circuit breaker according to the track of the auxiliary marker. According to the circuit breaker moving contact motion characteristic measurement method based on deep learning, non-contact measurement is adopted, and a component which moves synchronously with the circuit breaker moving contact is tracked to measure the motion characteristic of the circuit breaker moving contact, so that the problems of target size change, background color interference and camera shaking can be effectively solved; and accurate tracking is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Four-finger centripetal motion parallel mechanism palm manipulator capable of hooking and pinching

The invention relates to a four-finger centripetal motion parallel mechanism palm manipulator capable of hooking and pinching, and belongs to the technical field of robots and automation. A crank rotating motor of a dual-drive five-rod sliding block parallel mechanism cooperates with a lead screw motor for moving hinge bases of rockers; lead screws rotate forwards and backwards to enable the two hinge bases of the four rockers to move linearly in the opposite direction or the north direction, the rotation of four cranks of the parallel mechanism is combined to enable four fingers to move towards the center of the manipulator, and the four finger components are installed on the connecting rods or the rockers to pinch grabbed objects; and for horizontally-placed curved-surface-shaped grabbedobjects such as cylinders, spheres and ellipsoids, after the side faces of the fingers are close or a small contact force makes contact with the grabbed objects and before the manipulator moves, fingertip parts are driven by flexible shafts to rotate and hook the side bottoms of the grabbed objects, so that a clamping force for pinching is greatly reduced, and reliable grabbing is achieved.

Owner:JIANGNAN UNIV

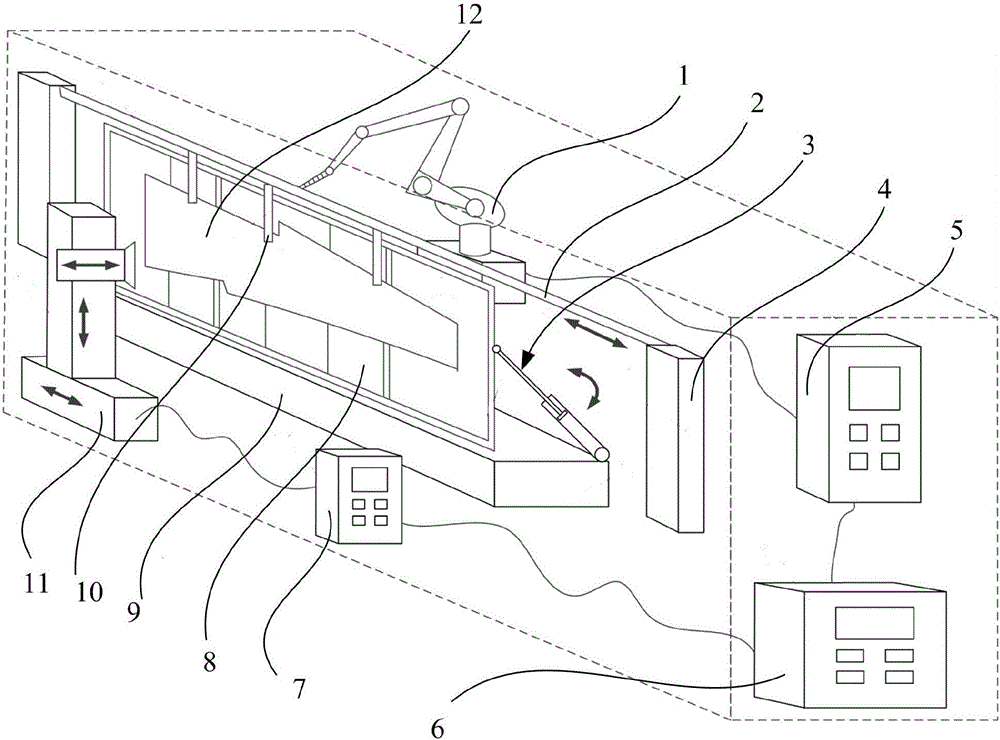

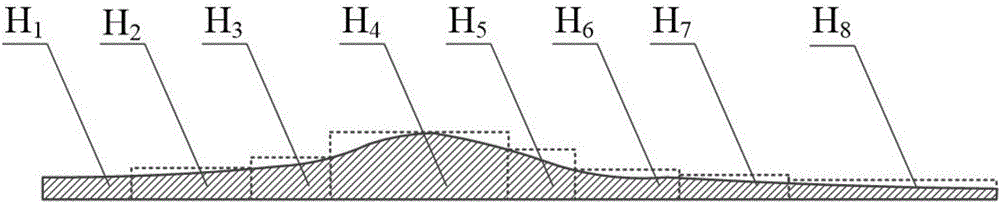

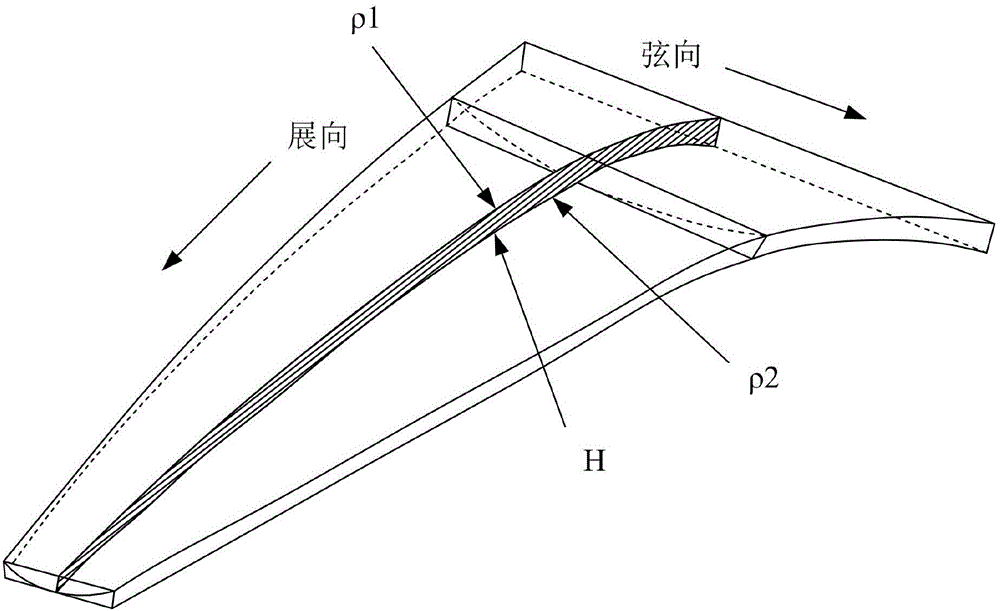

Vertical overturning laser peening forming device for integral aircraft wing panel and processing method

The invention discloses a vertical overturning laser peening forming device for an integral aircraft wing panel. The device comprises an overturning base, an overturning worktable, a telescoping hydraulic cylinder, a slide rail controller, a movable slide rail, a seven-degree-of-freedom laser peening unit, a laser peening unit system host, a total system host, an image processing host, a three-degree-of-freedom optical in-situ measurer and panel clamping units. The invention further discloses a processing method. For the method, area-separated laser peening forming and forming precision optimization are performed firstly under assistance of an online in-situ measurement technology through geometric shape analysis and equal-strength area division of the panel, then integral laser peening forming and area repair of the panel are performed, and finally, forming dimensions are detected. Compared with the prior art, forming of integral aircraft wing panels with various dimensions and complex curved surfaces can be realized, the laser peening forming device has the characteristics of high dimension adaptability, large forming curvature, controllable forming precision, high workpiece surface quality and the like, and long service life and high-precision forming of the panel are realized truly.

Owner:GUANGDONG UNIV OF TECH

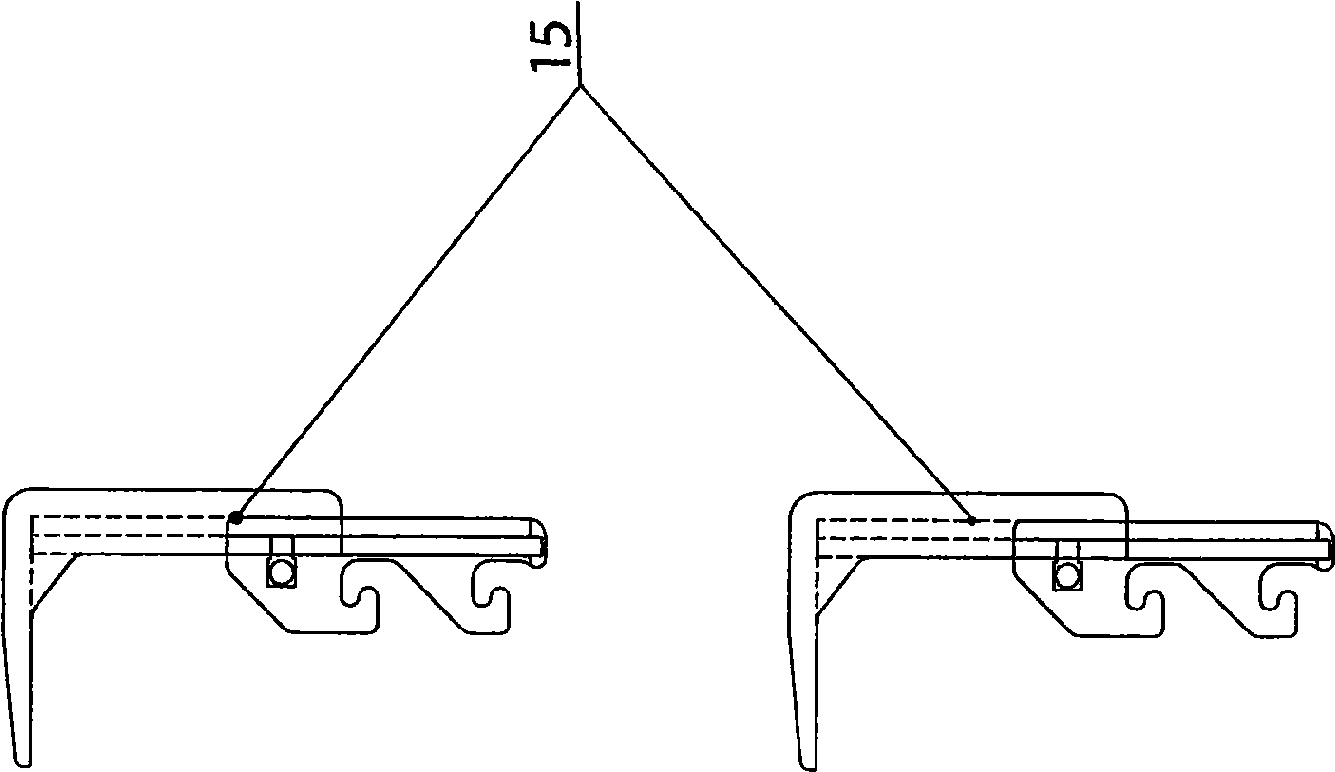

Notebook tray

InactiveCN101530260AImprove occupational painImprove visual fatigueDigital data processing detailsBed-tablesEngineeringLumbar

The invention relates to a notebook tray, which comprises a main tray (1), a backboard (2), side support blocks (4), a support post A (8), a support post B(9), a guide sleeve A (11), a guide sleeve B (12), a locking knob (13), a locking ring B(14) and press catches (15), wherein the guide sleeve A (11) and the guide sleeve B (12) pass through the middle of the support post A (8) and the support post B (9) respectively and are rotationally connected with the support post A (8) and the support post B (9); left and right ends of the support post A (8) and the support post B (9) are fixedly connected with two side support blocks (4) on the left and right respectively; the outer edge of the locking ring B (14) is rotationally connected with a groove on the main tray (1), and an inner hole is rotationally connected with the support post B (9); and the press catches (15) are in sliding connection with horizontal chutes on the rear side of the main tray (1) and vertical chutes on the support blocks (4). The notebook tray is matched with a computer support for use and can be adjusted at multiple angles in a wide range so as to improve occupational diseases such as visual fatigue, lumbar and cervical vertebra when a person uses a notebook to work, can adapt to specifications of most notebooks, is safe and reliable when the person works in a bedroom, and has firm and reasonable clamping to effectively protect the notebook.

Owner:江阴快力特机械有限公司

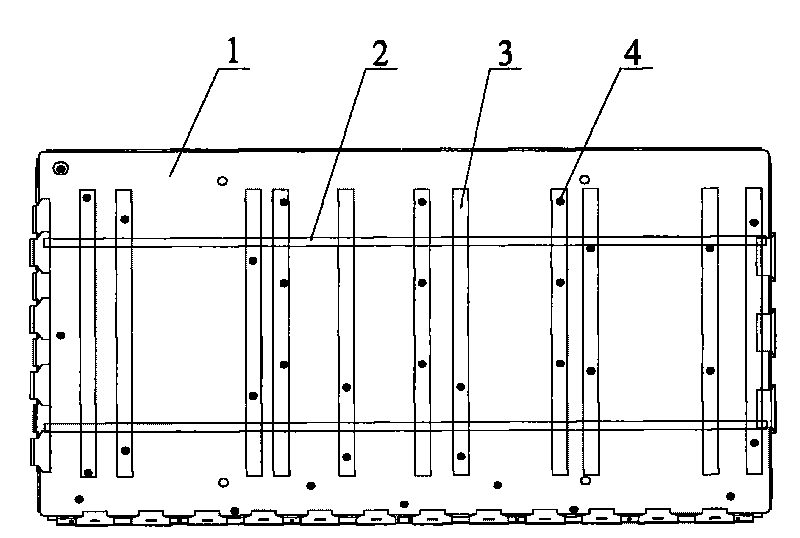

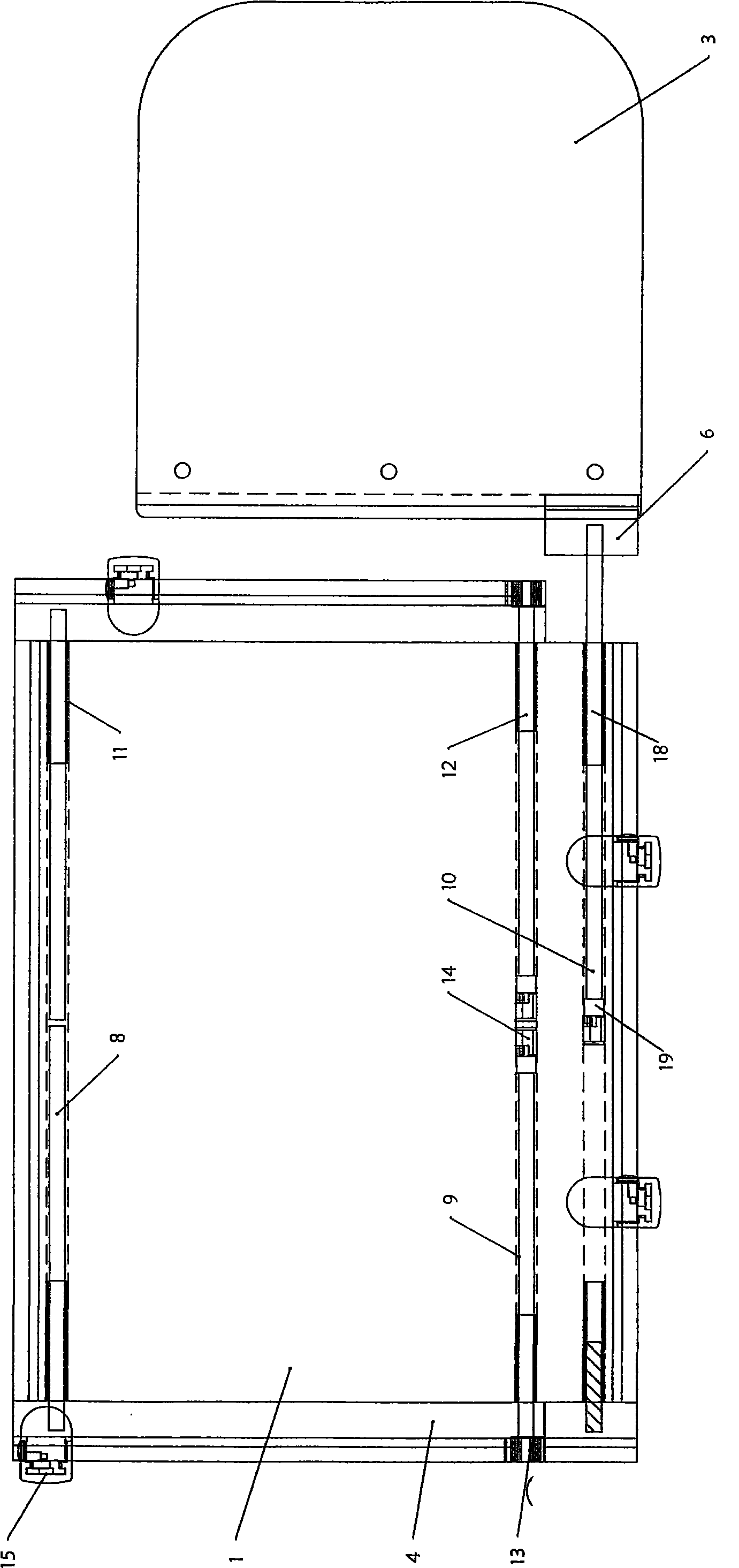

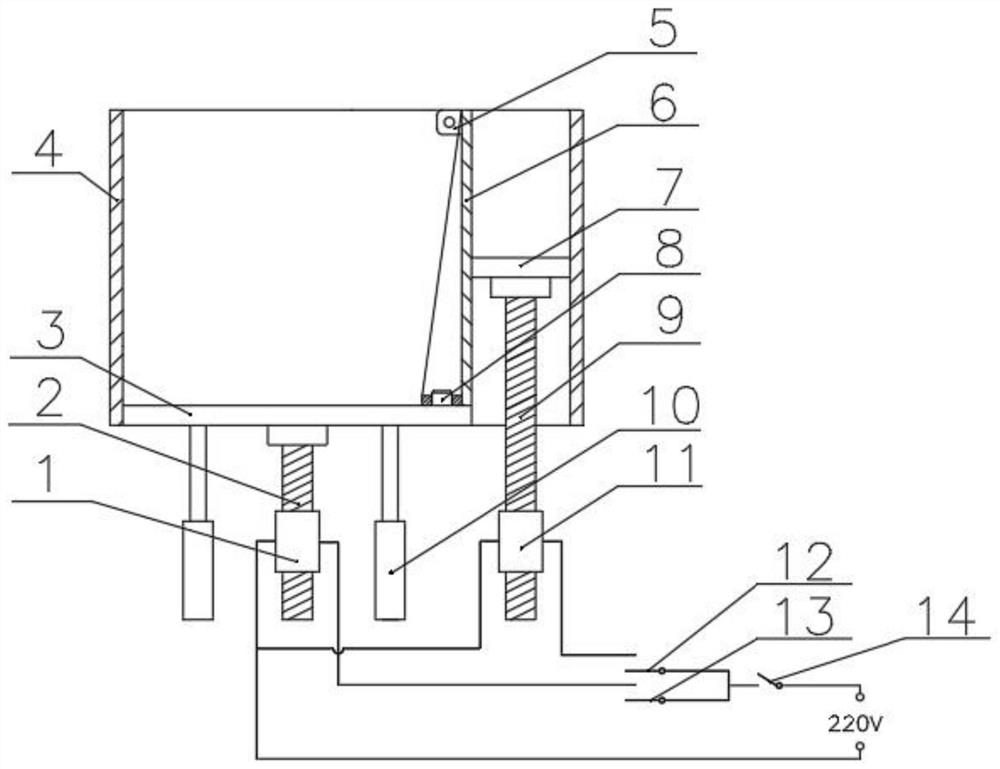

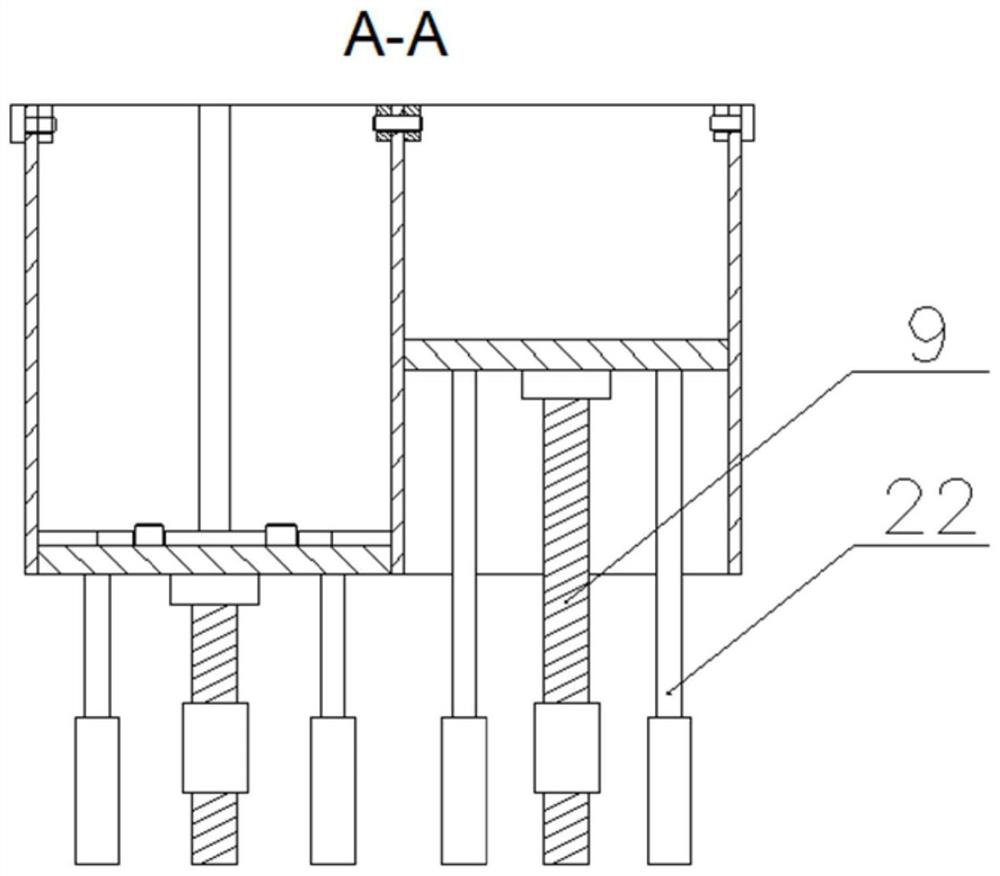

Using method and structure of large-small size fast switching 3D printing bin

PendingCN113733558AImproved size adaptabilityImprove space utilizationAdditive manufacturing apparatusElectric machineryStructural engineering

The invention provides a using method and structure of a large-small size fast switching 3D printing bin. A small-size printing bin used for printing small-size objects is divided in a large-size printing bin through a partition plate; when the large-size printing bin is used, a main bottom plate and an auxiliary bottom plate are in linkage lifting; and when the small-size printing bin is used, only the auxiliary bottom plate ascends and descends. A lifting device comprises a first motor, a second motor, a first lead screw and a second lead screw, the first motor is connected with the main bottom plate through the first lead screw, and the second motor is connected with the auxiliary bottom plate through the second lead screw. A control circuit system comprises a first switch used for controlling on-off of the second motor, a second switch used for controlling on-off of the first motor, and a main switch, the first switch and the second switch are arranged on two branches of A parallel circuit respectively, and the main switch is arranged on a main circuit. The large-size or small-size printing bin can be reasonably selected according to the size of parts, and the advantages of powder saving, high powder utilization rate, high printing efficiency, convenience in assembly and disassembly and the like are achieved.

Owner:SOUTH CHINA UNIV OF TECH

Garlic planting device

InactiveCN105706593AImproved size adaptabilityOpen quicklyTransplantingSeed depositing seeder partsAgricultural engineeringCam

The invention provides a garlic planting device. The garlic planting device comprises an inner plate, an outer plate and a planting device frame, wherein the two sides of the inner plate are symmetrically folded in the same direction, the two sides of the outer plate are symmetrically folded in the same direction, and a square hole is formed in the middle of the planting device frame. The garlic planting device is characterized in that the folded edges of the two sides of the inner plate extend into the folded edges of the two sides of the outer plate, the folded edges of the two sides of the inner plate are each additionally provided with a rotating shaft, the axes of the rotating shafts are overlapped, the rotating shafts penetrate through through holes formed in the two folded edges of the two sides of the outer plate respectively from inside to outside to be supported on the planting device frame, the upper portion of the inner plate and the upper portion of the outer plate are separated and extend into the square hole formed in the planting device frame, and the lower portion of the inner plate is attached to that of the outer plate. Fixing lugs are arranged on the portions, close to the outside, of the folded edges of the same side of the inner plat and the outer plate respectively and used for fixing the two ends of an extension spring respectively, and the portions, located below the rotating shaft, of the folded edges of the other side of the inner plate and the outer plate are provided with an inner stop block and an outer stop block respectively; a cam is additionally arranged under the rotating shaft and between the inner stop block and the outer stop block. The garlic planting device can be opened in a bilaterally symmetrical mode and is high in erecting rate, simple and compact in structure and suitable for erecting planting of garlic and rice seedlings.

Owner:SHANDONG UNIV OF TECH

Rotation lifting mechanism of horizontal joint robot

ActiveCN111775157AMeet the use requirementsHelp miniaturizationProgramme-controlled manipulatorAlcoholic beverage preparationElectric machineryEngineering

The invention relates to a rotation lifting mechanism of a horizontal joint robot, wherein the upper end of a hollow shaft is connected to a forearm belt conveyor, and the other end is inserted into arotation cylinder; an electric conduction slide ring sleeves the rotation cylinder, a rotation motor is installed on a shell and is connected to the upper end of an inner rotation part of the electric conduction slide ring by a rotation transmission mechanism, the lower end of the inner rotation part is connected to the rotation cylinder, an outer fixation part is fixedly connected to the shell,and a lip-shaped seal ring is disposed under the electric conduction slide ring; an upper press ring is installed on the inner rotation part, a lower gasket is relatively fixed to the rotation cylinder, and a seal flexible ring is disposed between the upper press ring and a lower press ring; and a lifting motor is installed on a forearm and is connected to a lifting part by a lifting transmissionmechanism, a lifting part is driven to drive the rotation cylinder to realize ascending and descending relative to the hollow shaft, and dynamic sealing is realized between the rotation cylinder and the hollow shaft by the upper press ring, the seal flexible ring and the lower gasket. The mechanism provided by the invention can facilitate miniaturization of a joint speed reduction mechanism, facilitate joint sealing and facility increase of a cleanliness grade of equipment.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Pin cut-off machine capable of improving machining efficiency easily

The invention discloses a pin cut-off machine capable of improving machining efficiency easily. The pin cut-off machine comprises a machine frame and cutters arranged on the machine frame. A feeding device and a cutter braking device are further arranged on the machine frame. The feeding device comprises a fluted disk shaft and four feeding fluted disks. Fluted disk bolts are arranged on the feeding fluted disks, and a driving part is further arranged on the fluted disk shaft. A cutter sliding rail is further fixed to the machine frame, and the number of the cutters is two. The cutter braking device comprises two cutter clamping blocks, a clamping block rail and a cutter screw rod, and cutter clamping grooves are further formed in the cutter clamping blocks. The pin cut-off machine is simple in structure, high in machining efficiency, low in maintenance cost and suitable for various raw materials in different sizes.

Owner:CHENGDU ZHONGSHAN SCI & TECH

Photovoltaic panel frame structure with high versatility

InactiveCN106533335AAdjustable angleLarge adjustment rangePhotovoltaic supportsPhotovoltaic energy generationEngineeringElectrical and Electronics engineering

The invention discloses a photovoltaic panel frame structure with high versatility. The structure comprises a fixing frame and a photovoltaic panel fixing board. A plurality of buckles are fixed on the photovoltaic panel fixing board. The structure further comprises locking bolts. The lower end of the photovoltaic panel fixing board is fixedly connected with locking boards. The locking bolts penetrate through the locking boards. Furthermore the photovoltaic panel fixing board can rotate around the axis of the locking bolt. The fixing frame is also provided with hinging blocks. The structure further comprises adjusting rods. The hinging blocks are hinged with the lower ends of the adjusting rods. The upper end of each adjusting rod is hinged with a slide board. The slide board is fixedly connected with the photovoltaic panel fixing board, and furthermore the connecting point position between the slide board and the photovoltaic panel fixing board can be adjusted. Each buckle comprises a pressing board, a fastening slide block and a compressing bolt. Furthermore the photovoltaic panel fixing board is provided with adjusting troughs. The photovoltaic panel frame structure has advantages of simple structure, convenient realization of photovoltaic panel angle adjustment relative to a horizontal surface, low dependence on landform, high convenience in transportation, and high adaptability for dimension of the photovoltaic panel.

Owner:胡峻源

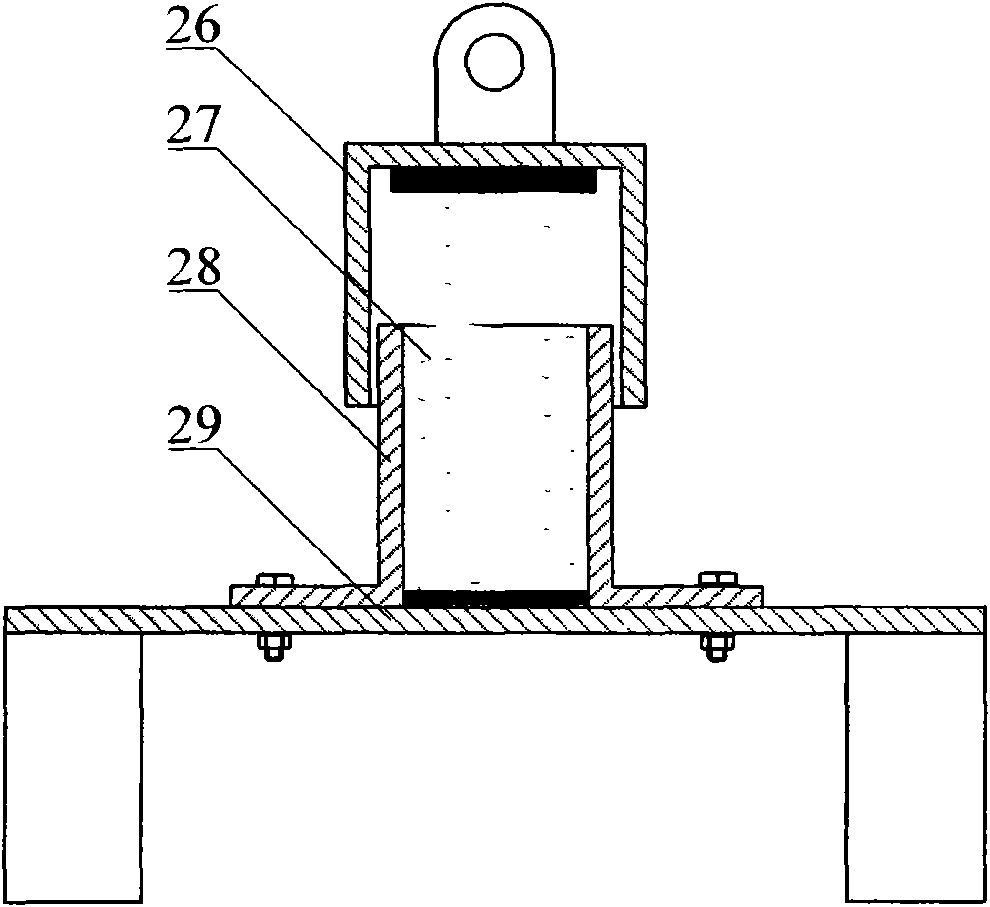

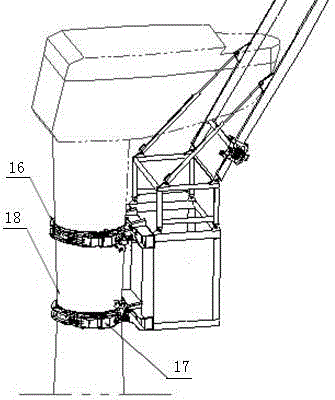

Tower holding device for wind power maintenance crane

InactiveCN103359637BEasy to fixEasy to disassembleWind energy generationCranesElectricityWind driven

The invention provides a tower embracing device for a wind electricity overhauling crane. The tower embracing device for the wind electricity overhauling crane comprises an upper tower embracing device; the upper tower embracing device comprises a left hand embracing mechanism, a right hand embracing mechanism and a middle tower embracing ring; the left hand embracing mechanism and the right hand embracing mechanism are hinged with two ends of the middle tower embracing ring respectively. The tower embracing device enables a maintaining and detecting device to be conveniently fixed on a tower cylinder and to be detached conveniently; when the tower embracing device is in use, the upper tower embracing device embraces the tower cylinder tightly, and thus the operation need of the maintaining and detecting device is ensured; after overhauling, the upper tower embracing device is unfolded, and the overhauling crane is lowered and put in storage. The tower embracing device for the wind electricity overhauling crane can be suitable for overhauling of different wind driven generator sets, saves the maintaining cost of a wind power station greatly, and is simple in structure, low in cost and convenient to use.

Owner:CHINA RESOURCES NEW ENERGY HLDG CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com