Flexible edge sealing mechanism for automatic edge sealing machine of solar dual-glass battery module

A technology of battery components and flexible mechanisms, which is applied in the direction of electrical components, circuits, photovoltaic power generation, etc., can solve the problems of restricting rapid promotion, difficult quality control, poor appearance, etc., and achieves beautiful appearance, high attachment accuracy, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

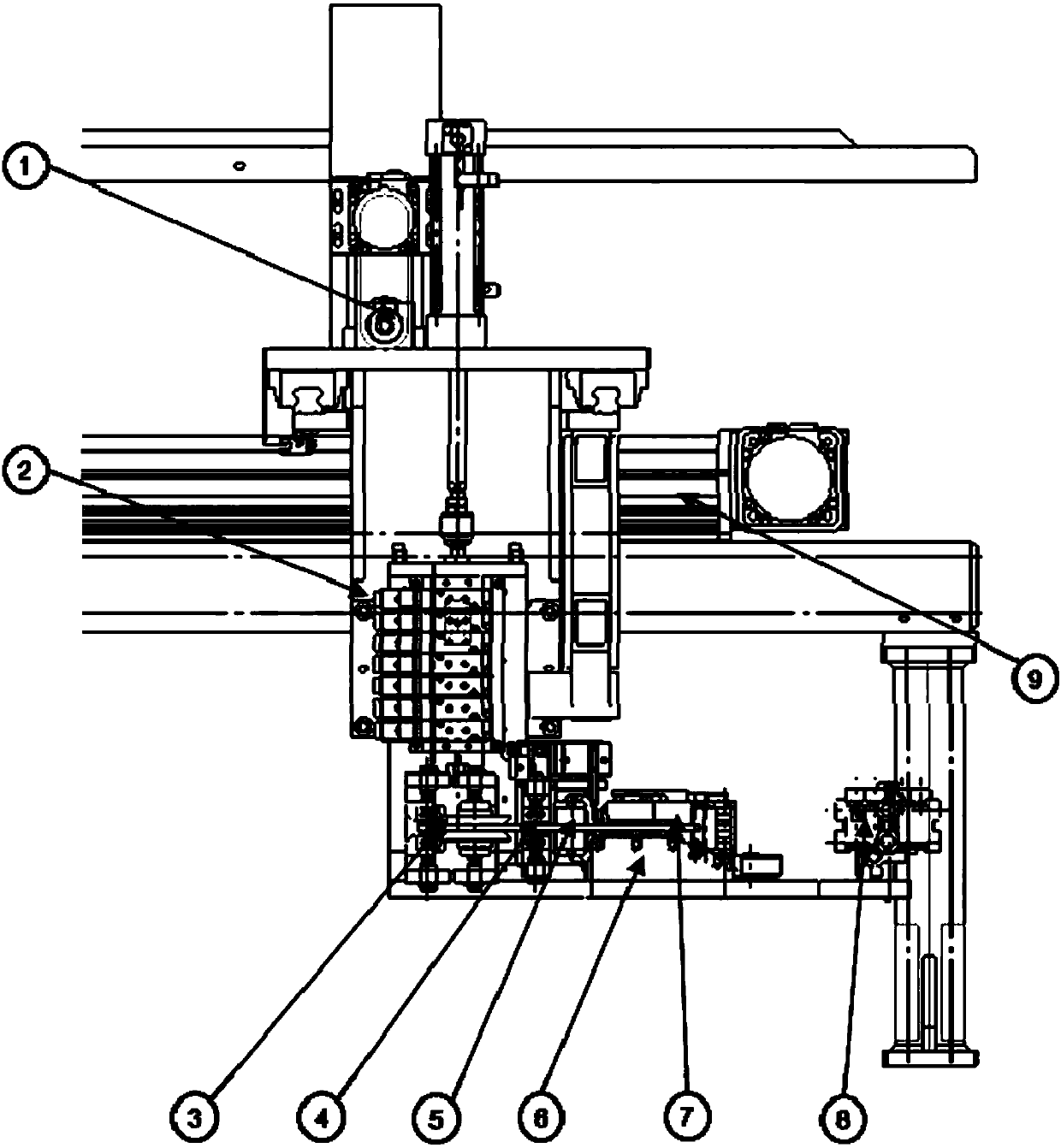

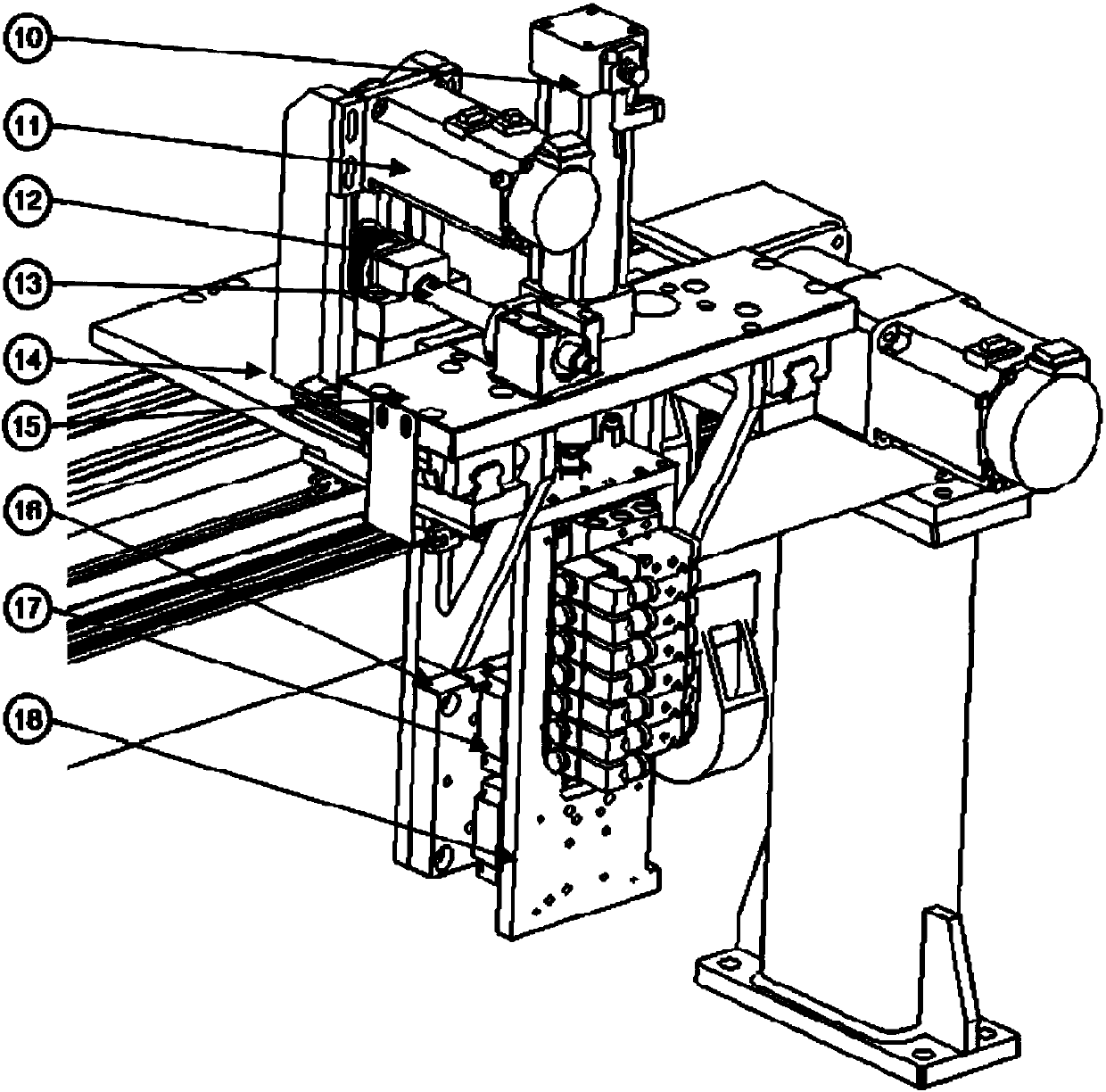

[0021] like Figure 1 to Figure 6 As shown, this embodiment provides a flexible edge sealing mechanism for an automatic edge sealing machine for solar double-glass battery modules, which includes a mobile adjustment mechanism and a flexible edge sealing mechanism substrate 53 connected to the mobile adjustment mechanism; the flexible sealing mechanism The left section of the side mechanism substrate 53 is provided with a flexible mechanism mounting plate 54, the middle section is provided with a glass guide mechanism 6 at the front position, the tape guide positioning mechanism 7 is provided at the rear position of the middle section, and the right section is provided with an adhesive tape Feeding mechanism 8; the flexible tape forming mechanism 3 and the flexible tape kneading mechanism 4 are sequentially installed on the flexible mechanism mounting plate 54 from left to right.

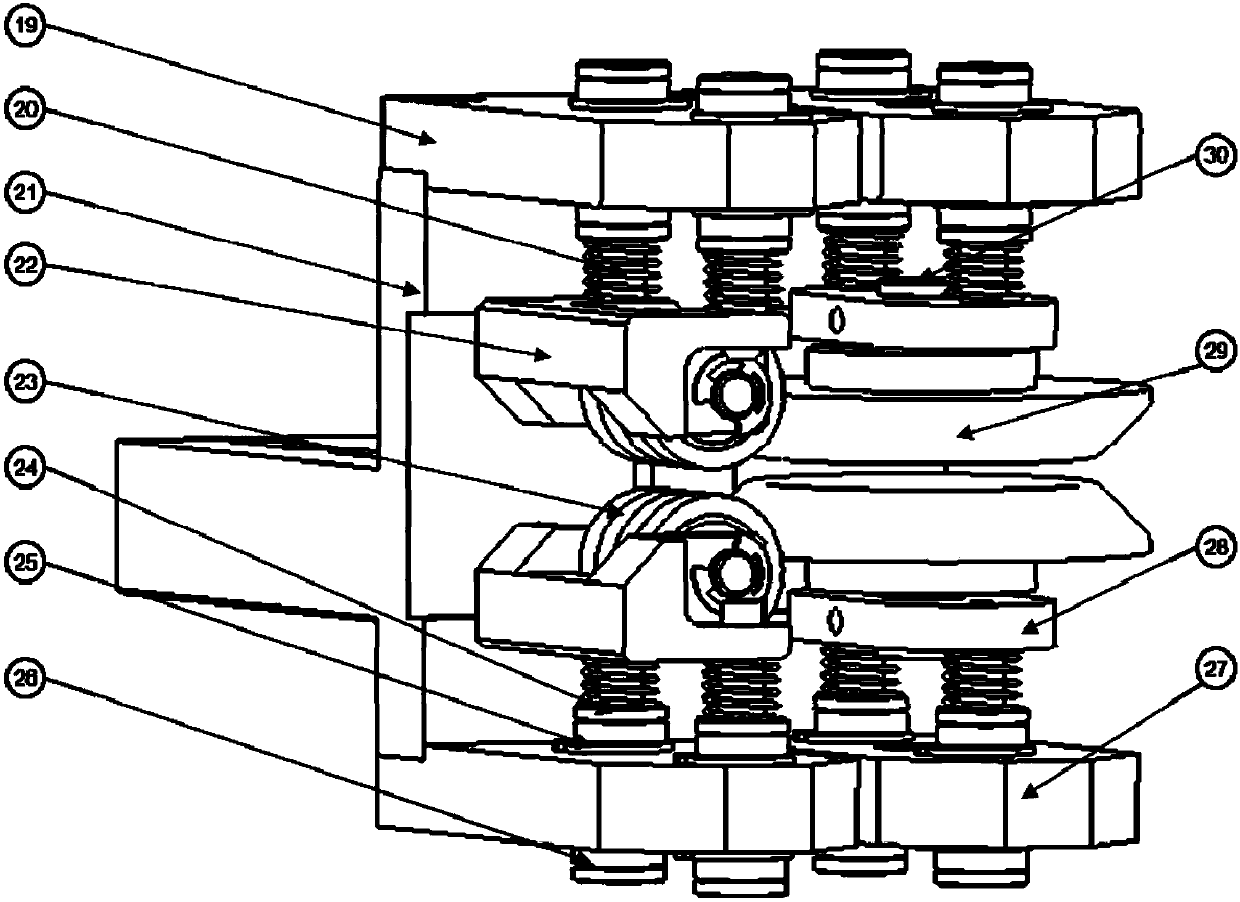

[0022] like image 3 As shown, the flexible tape forming mechanism 3 includes a roller guiding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com