Using method and structure of large-small size fast switching 3D printing bin

A technology of rapid switching and printing bins, applied in the direction of additive processing, etc., can solve the problems of poor adaptability to the size of the printed parts, and the space of the printing bin cannot be adjusted according to the demand, so as to achieve powder saving, simple structure and good size adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation of the present invention will be further described below in conjunction with examples, but the implementation and protection of the present invention are not limited thereto. It should be pointed out that, if there are any processes in the following that are not specifically described in detail, those skilled in the art can realize or understand with reference to the prior art. The reagents or instruments used were not indicated by the manufacturer, and they were regarded as conventional products that can be purchased from the market.

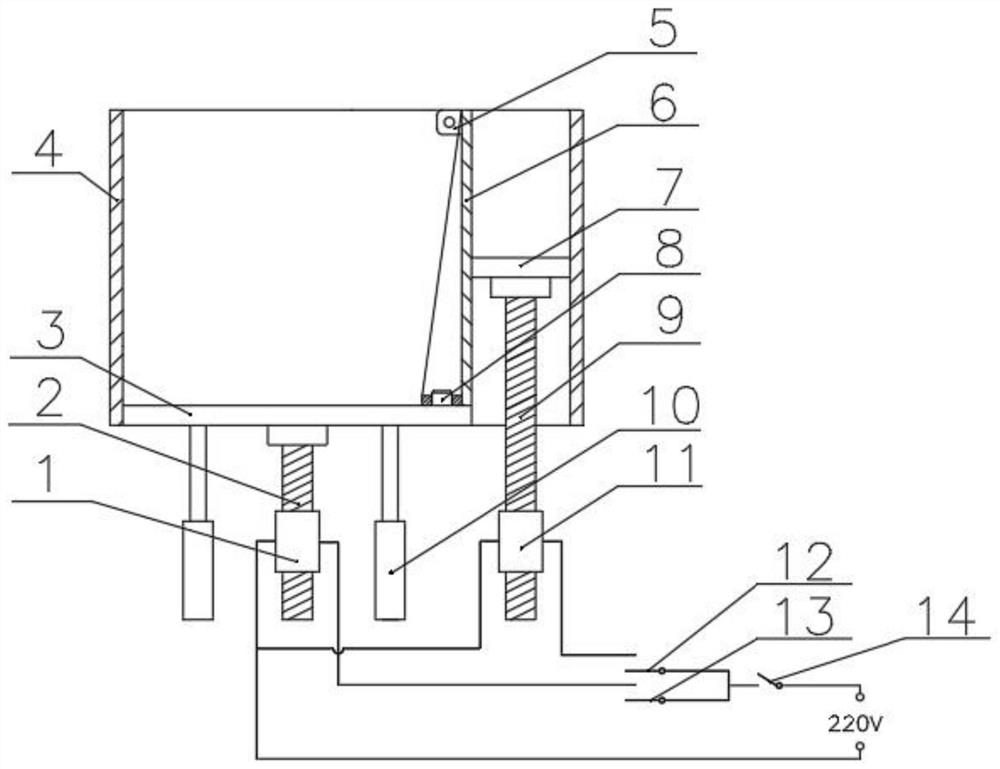

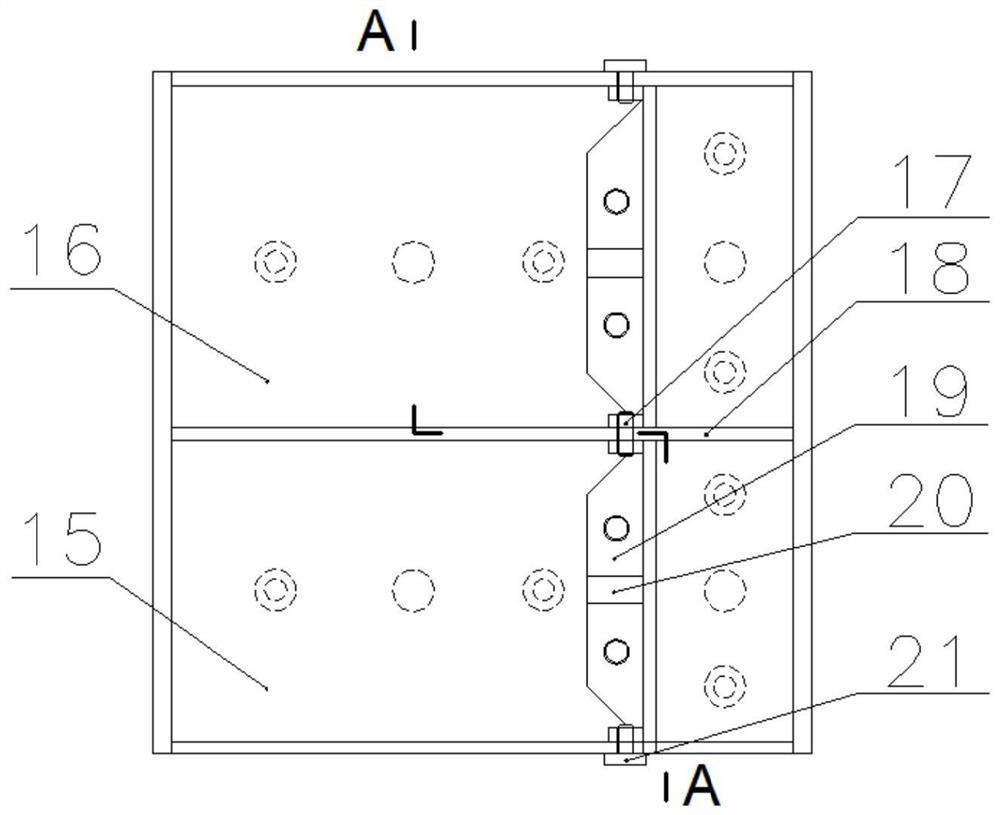

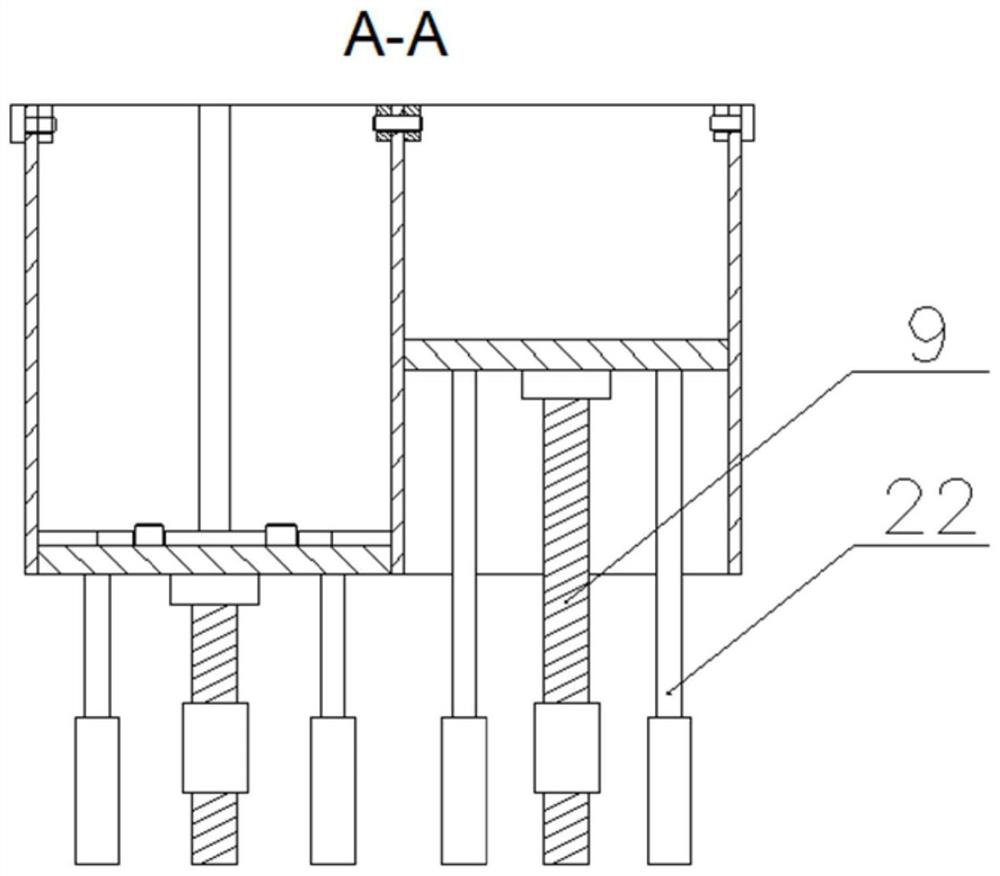

[0043]The present invention provides a 3D printing chamber with fast switching between large and small sizes, including: a large-size printing chamber, a partition 6, a main base plate 3, an auxiliary base plate 7, a lifting device and a control circuit system. The bottom plate of the printing chamber is set into two parts, one part is the main bottom plate 3, and the other part is the sub-bottom plate 7, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com