Pin cut-off machine capable of improving machining efficiency easily

A technology of processing efficiency and cutting machine, applied in the field of cutting machine, can solve the problems of further improvement of resistance pin cutting efficiency, low production efficiency, low dimensional accuracy, etc., and achieves simple structure, high feeding efficiency and high processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

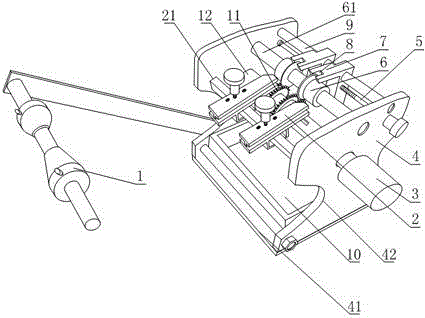

[0022] Such as figure 1 As shown, a kind of foot shearing machine that is conducive to improving processing efficiency includes a frame 4 and a cutter 6 arranged on the frame 4, and the shown frame 4 is also provided with a feeding device and a cutter 6 braking device;

[0023] The feeding device shown includes a toothed disc shaft 12 arranged on the frame 4, and a feeding toothed disc 11 keyed to the toothed disc shaft 12. The number of the shown feeding toothed discs 11 is four, and the feeding toothed discs 11 are all threaded. A toothed plate bolt for fixing the feeding toothed plate 11 is connected, and a driving part 3 for braking its rotation is also fixedly connected to the toothed plate shaft 12;

[0024] The shown cutter 6 is a disk-shaped structure provided with a central hole, and the frame 4 is also fixed with a cutter slide rail 61, the shown cutter 6 is matched with the cutter slide rail 61, and the number of the cutter 6 is two. One, the axis of cutter slide r...

Embodiment 2

[0029] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, in order to facilitate the assembly of the present invention, the frame 4 includes a bottom plate and two side plates 42 arranged on the bottom plate, wherein at least one side plate 42 is detachably connected. In the above structure, the bottom plate and one of the side plates 42 can be integrally arranged as a whole, which can be formed by casting or bending, and the frame 4 can be obtained by bolt connection between the two side plates 42, so that When the present invention is assembled, the feeding device and the cutter 6 braking device can be fixed on the fixed side plate 42 and then the installation of the detachable side plate 42 can be completed.

Embodiment 3

[0031] The present embodiment is further limited on the basis of embodiment 1, as figure 1As shown, in order to allow electronic components such as resistors and capacitors to accurately fall into the pin cutting support part, the frame 4 is also provided with a material traction part, and the traction part includes a traction rail 2 and an axis and a toothed disc shaft 12. An axis-parallel traction slide bar 21, the traction slide bar 21 is fixed on the frame 4, the traction rail 2 is fixed on the traction slide bar 21, and the position of the traction rail 2 on the traction slide bar 21 is adjustable. In the above structure, the traction rail 2 can be a plate-like, sheet-like or groove-like structure.

[0032] In order to maintain the position of the cutter 6 conveniently, a locking nut is threadedly connected to the cutter screw 5 , and the end of the locking nut is in contact with the frame 4 or the cutter block 7 . In the above structure, the purpose of fixing the cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com