Medium-temperature foil type resistance strain gauge

A resistance strain gauge, foil-type technology, applied in the field of medium-temperature foil resistance strain gauge, can solve the problems of increased discreteness of strain gauge measurement data, drift of strain gauge output signal, and deterioration of strain gauge stability, etc., to achieve improved Stability and reliability, good consistency of measurement accuracy, effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

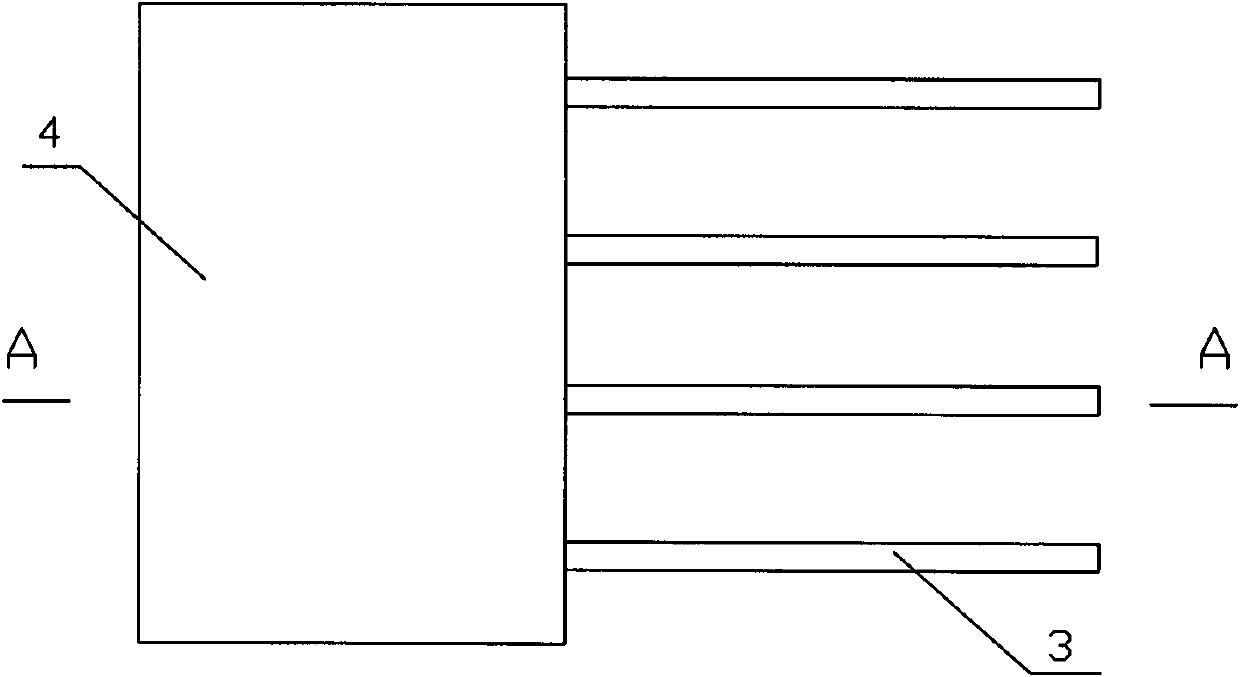

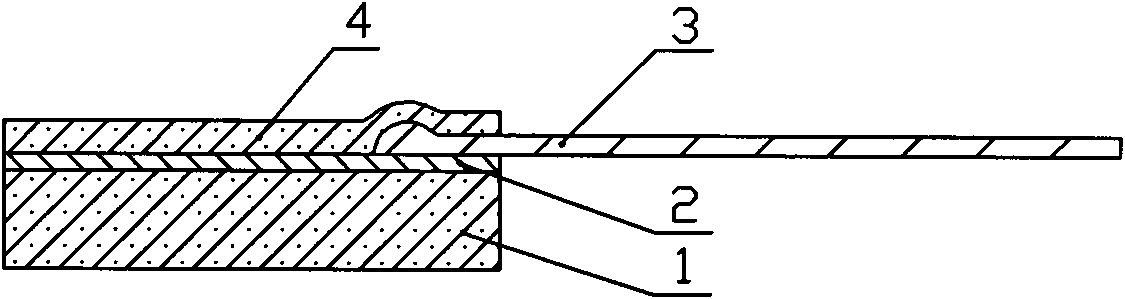

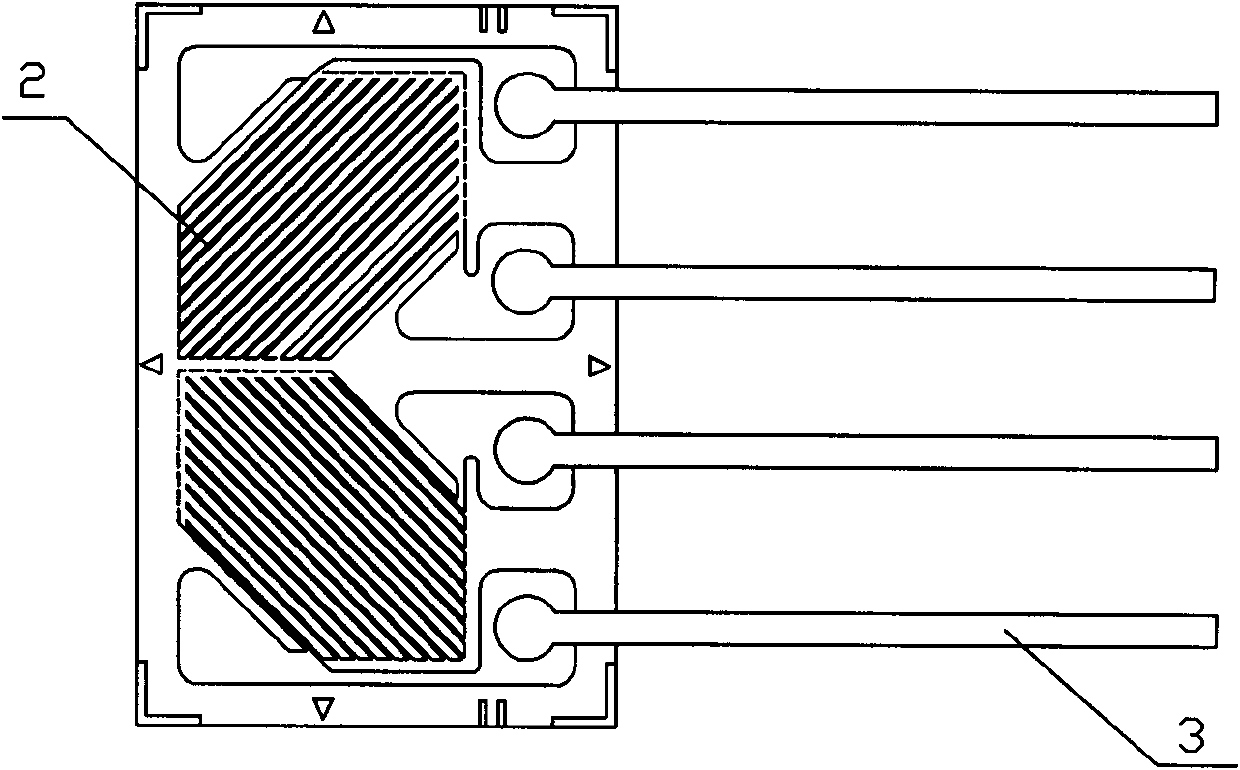

[0017] Such as figure 1 and figure 2 As shown, the strain gauge of this embodiment is composed of a glass fiber reinforced polyimide base 1 , a sensitive grid 2 and a polyimide sealing layer 4 , and the sensitive grid 2 is firmly attached between the base 1 and the sealing layer 4 .

[0018] In the manufacturing process, the copolymerized aromatic polyimide glue is first mixed with the surface-treated quartz filler and nano-scale silicon powder, and the mixed glue is coated on the Karma alloy foil or Ewen alloy foil or nickel-chromium The back of the alloy foil, and then spread a layer of glass fiber on the mixed rubber surface, and then form a strain gauge substrate with metal foil by high temperature heating and pressure, and the glass fiber reinforced polymer on the substrate The imide part is the substrate 1 of the strain gauge; the formation of the sensitive gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com