External wall insulation board and manufacturing method thereof

A technology of external wall thermal insulation board and perlite thermal insulation board is applied in thermal insulation, manufacturing tools, building components, etc., and can solve the problems of corrugated steel wire and metal reinforcement strip being easily deformed by compression, low production efficiency, low tensile strength, etc. Achieve the effect of overcoming brittleness, high production and processing efficiency, and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

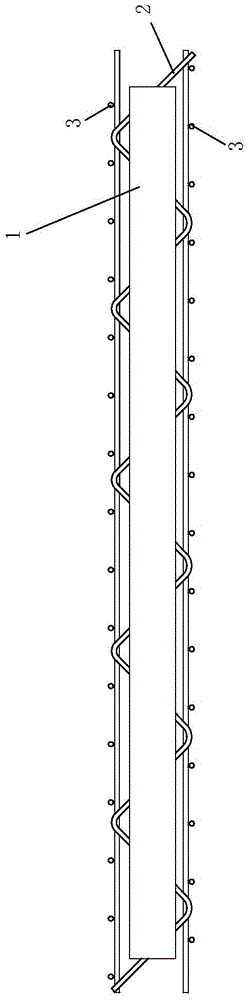

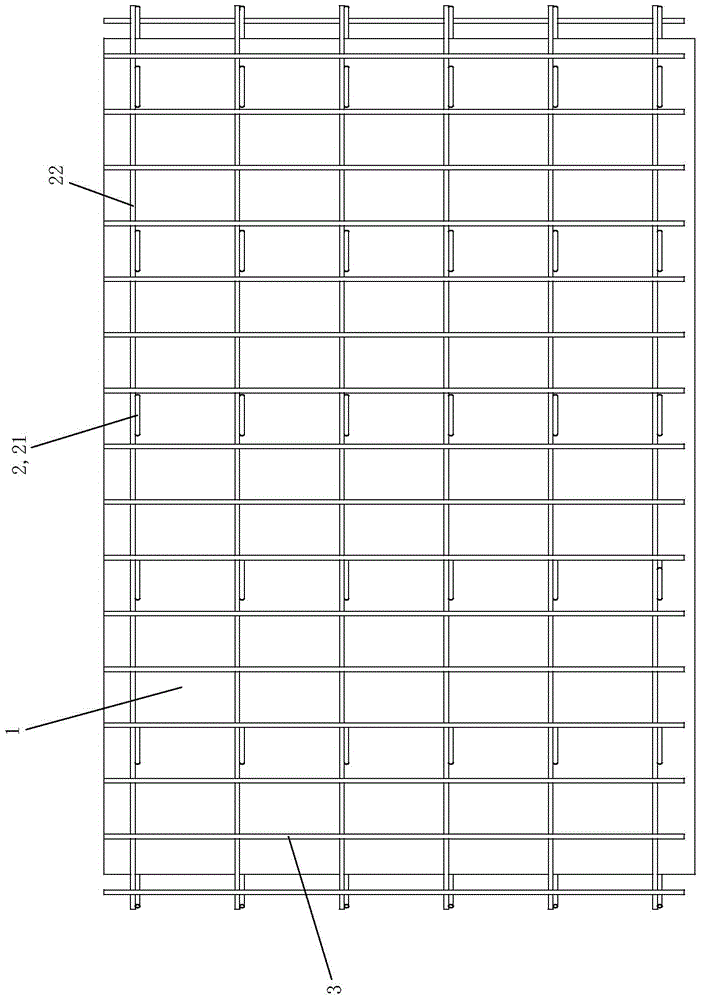

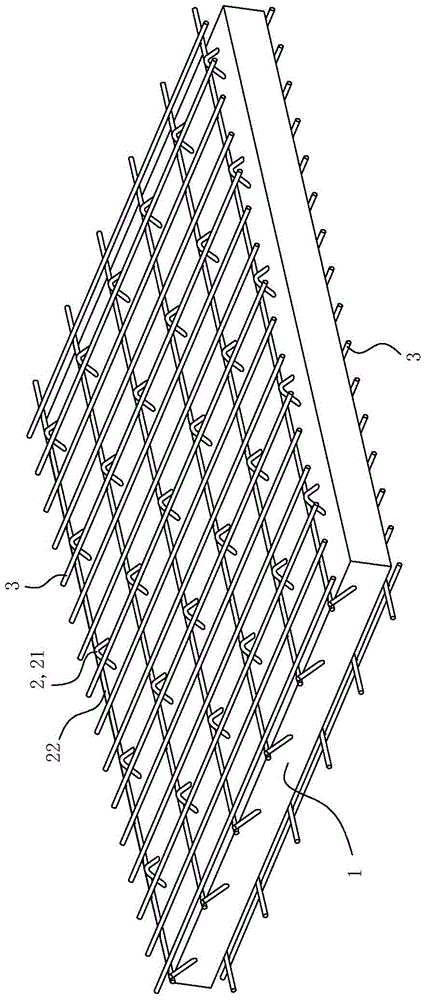

[0038] See Figure 1 to Figure 3 , The exterior wall thermal insulation board of the present invention includes a thermal insulation member 1, a truss 2 and a transverse reinforcement 3. The thermal insulation part 1 is an expanded perlite thermal insulation board or a cement foam thermal insulation board, and this embodiment is a perlite thermal insulation board pressed and formed by expanded perlite filler.

[0039] See figure 1 , Figure 3 to Figure 5 , there are several trusses 2, and there are six in this embodiment. The structures of the six trusses 2 are all the same. Each truss 2 includes oblique ribs 21 , upper ribs 22 and lower ribs 23 . The oblique ribs 21 are zigzag continuous structures arranged along the length direction of the thermal insulation element 1 . The upper ribs 22 are arranged horizontally along the length direction of the thermal insulation element 1 , and the upper ribs 22 are fixedly connected to the bends on the upper side of the oblique ribs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com