Full-color LED display module, packaging method and display screen of full-color LED display module

A technology of display module and packaging method, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of long time, complicated fluorescent film preparation process, inability to realize various selection of packaging sizes, etc., and meet the low requirements of packaging equipment , large size adaptability, the effect of ensuring the quality of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

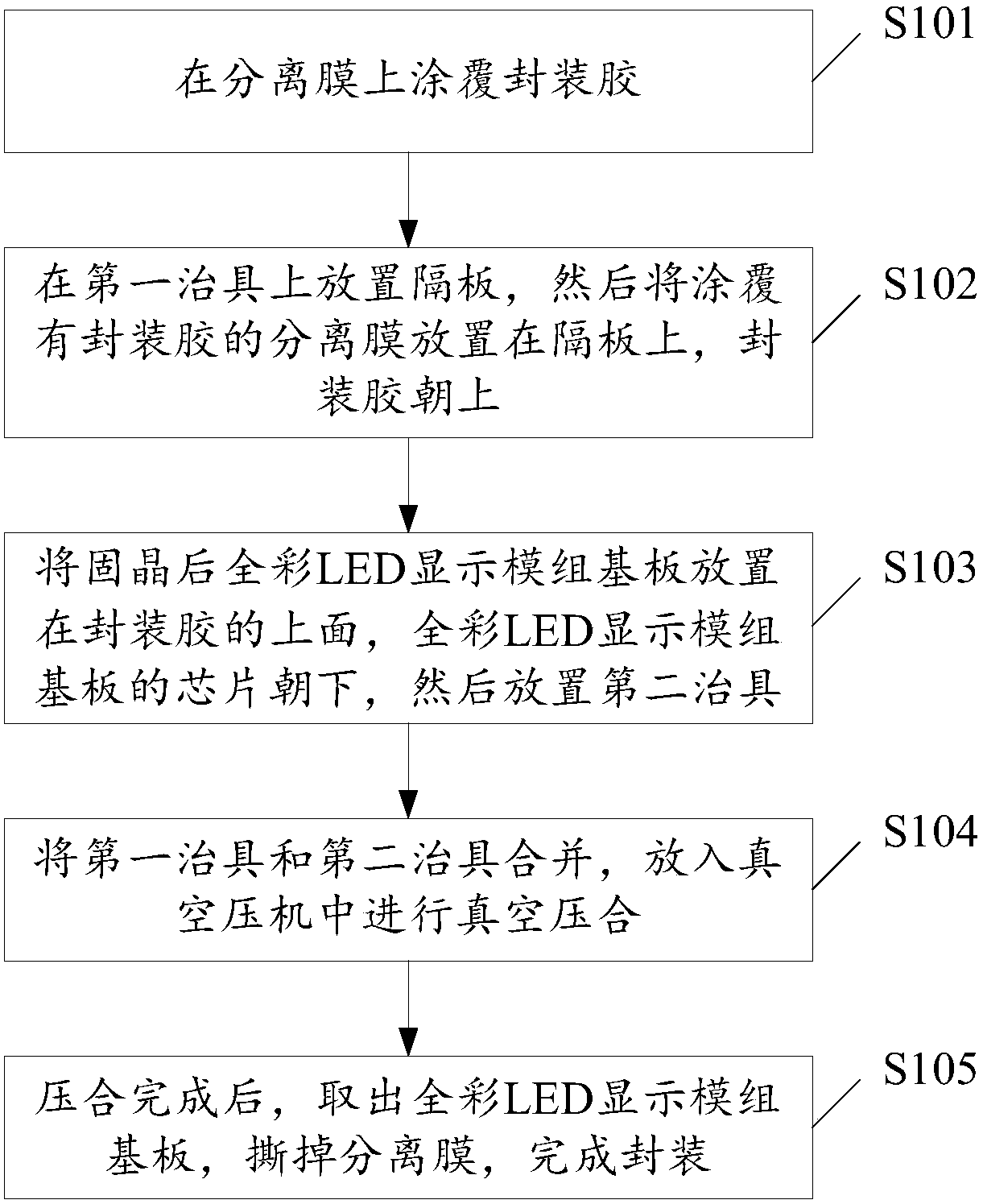

[0067] The packaging method of the full-color LED display module is as follows:

[0068] (1) A fluororesin film is selected as the separation membrane, and an encapsulation glue is coated on the separation membrane by printing. The encapsulation glue is prepared by mixing silica gel and a tackifier at room temperature, and the viscosity is 30 pa.s.

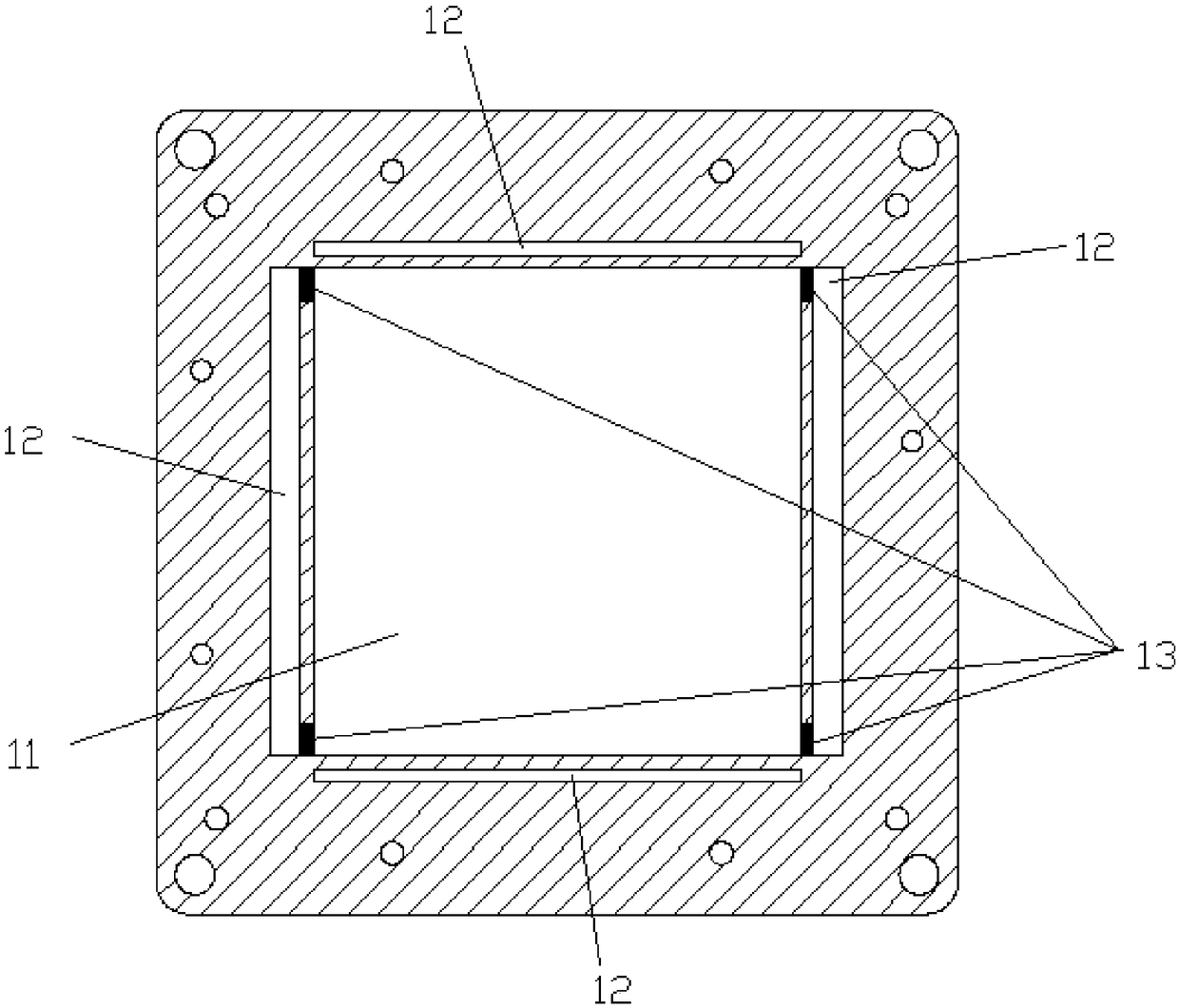

[0069] (2) Place on the first fixture such as figure 2 spacer as shown, then place the encapsulant-coated separation membrane on the spacer with the encapsulant facing up. The size of the separation membrane coated encapsulant is smaller than the size of the inner cavity of the separator, and the volume of the encapsulant is V 0 =50%*(V 1 +V 2 +V 3 ).

[0070] (3) Place the full-color LED display module substrate on the encapsulation glue after crystal bonding, with the chip of the full-color LED display module substrate facing down, and then place the second fixture.

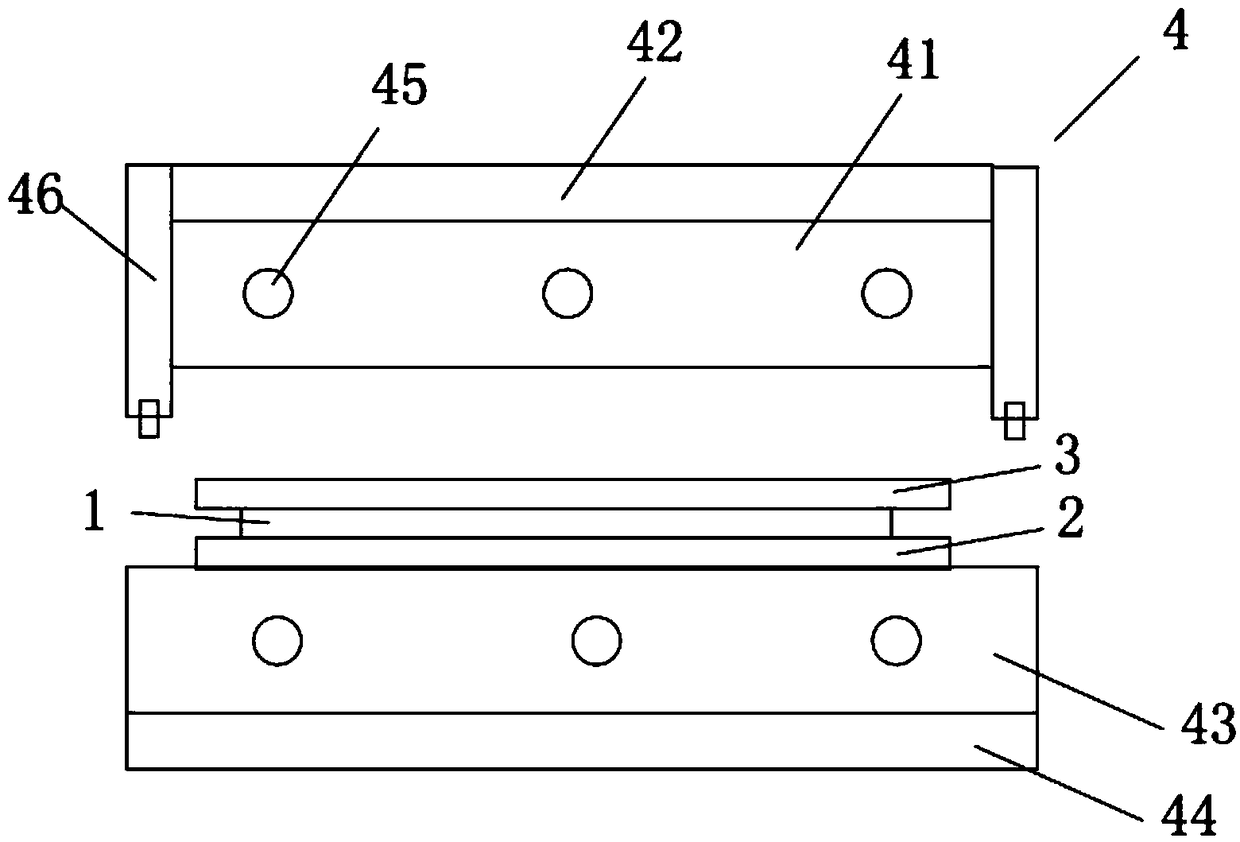

[0071] (4) Combine the first jig and the second jig, a...

Embodiment 2

[0074] The packaging method of the full-color LED display module is as follows:

[0075] (1) A fluororesin film is selected as the separation membrane, and an encapsulation glue is coated on the separation membrane by spraying. The encapsulation glue is prepared by mixing silicone resin and a tackifier at room temperature, and the viscosity is 40 pa.s.

[0076] (2) Place on the first fixture such as figure 2 spacer as shown, then place the encapsulant-coated separation membrane on the spacer with the encapsulant facing up. The size of the separation membrane coated encapsulant is smaller than the size of the inner cavity of the separator, and the volume of the encapsulant is V 0 =60%*(V 1 +V 2 +V 3 ).

[0077] (3) Place the full-color LED display module substrate on the encapsulation glue after crystal bonding, with the chip of the full-color LED display module substrate facing down, and then place the second fixture.

[0078] (4) Combine the first jig and the second ji...

Embodiment 3

[0081] The packaging method of the full-color LED display module is as follows:

[0082] (1) A fluororesin film is selected as the separation membrane, and the encapsulation glue is coated on the separation membrane by dispensing. The encapsulation glue is prepared by mixing silica gel, tackifier and carbon powder at room temperature, and the viscosity is 60pa.s.

[0083] (2) Place on the first fixture such as figure 2 spacer as shown, then place the encapsulant-coated separation membrane on the spacer with the encapsulant facing up. The size of the separation membrane coated encapsulant is smaller than the size of the inner cavity of the separator, and the volume of the encapsulant is V 0 =80%*(V 1 +V 2 +V 3 ).

[0084] (3) Place the full-color LED display module substrate on the encapsulation glue after crystal bonding, with the chip of the full-color LED display module substrate facing down, and then place the second fixture.

[0085] (4) Combine the first jig and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com