Sealing edge of rail vertical column and vertical column thereof

A column and fence technology, applied in the direction of fences, building types, buildings, etc., can solve the problems of excessive dust and affect assembly, and achieve the effect of good diversion, prolonging service life and improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

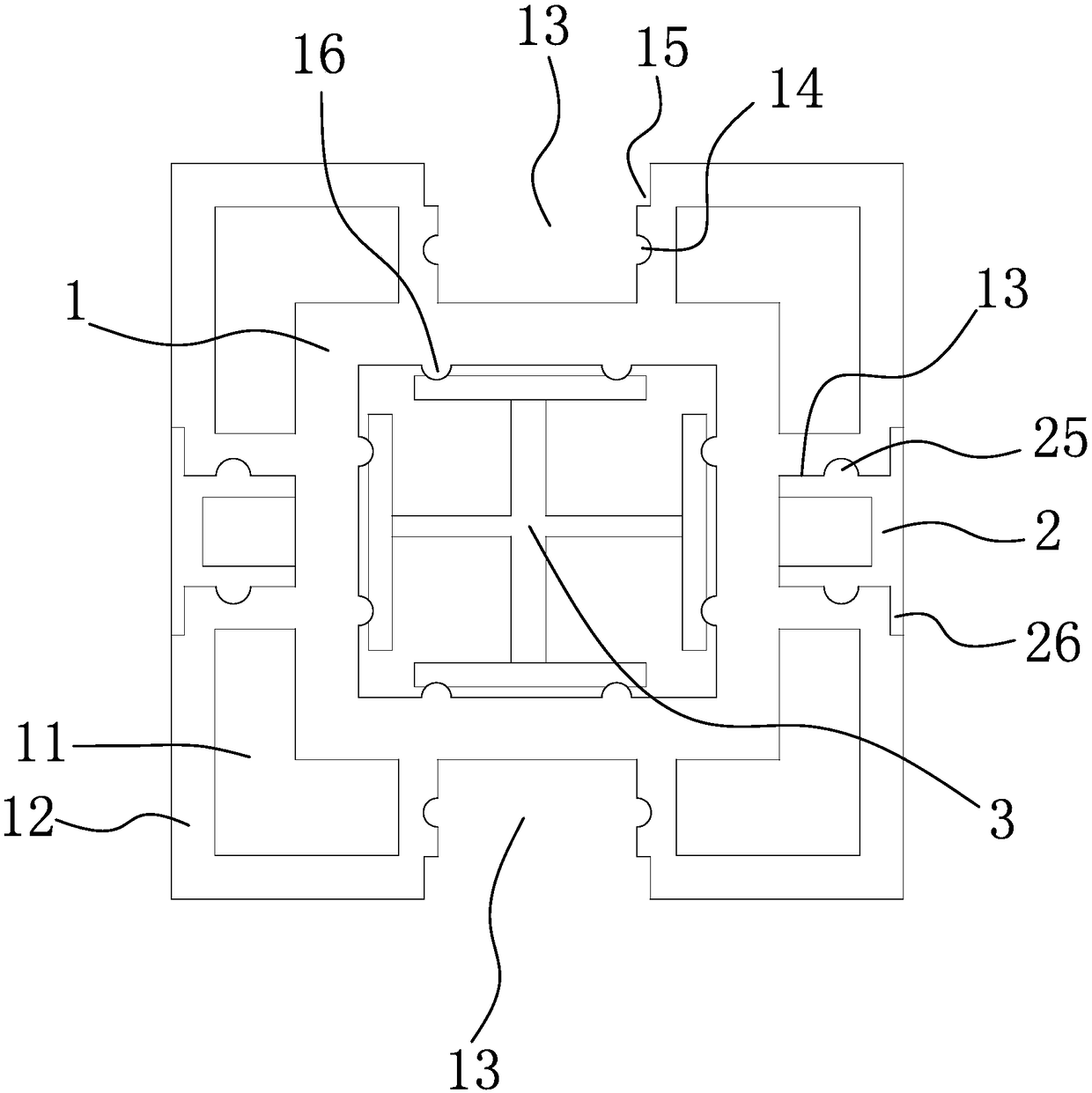

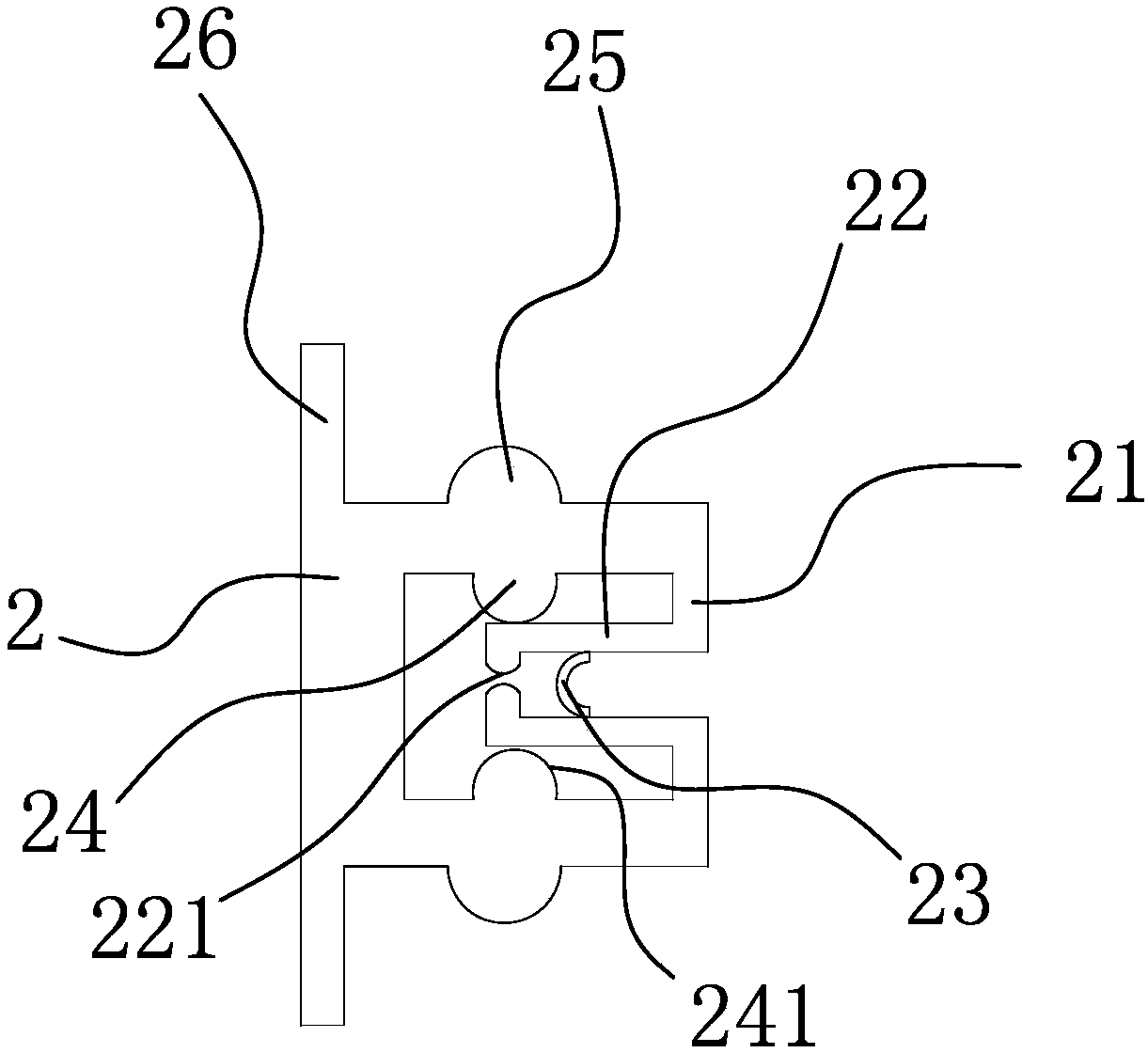

[0038] Such as Figure 1-2 as shown,

[0039] The edge sealing of this fence column includes a U-shaped part 2, with an inwardly extending extension 21 at both ends of the U-shaped part 2, and an L-shaped part 22 at the end of the extension 21 away from the U-shaped part 2, two L-shaped There is a gap between the two L-shaped parts 22, an elastic member 23 capable of forcing the L-shaped part 22 to expand outward is provided between the two L-shaped parts 22, and the inner wall of the U-shaped part 2 is provided with the L-shaped part. The reinforcing rib 24 that the free end of the part 22 contacts.

[0040] The end of the L-shaped portion 22 away from the extension portion 21 has an arc convex surface 221 .

[0041] The U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com