an automatic locking device

An automatic locking and locking block technology, applied in the direction of quick-acting fasteners, rigid shaft couplings, mechanical equipment, etc., can solve the problem of inability to install and remove, and achieve the effect of convenient manufacturing, easy installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

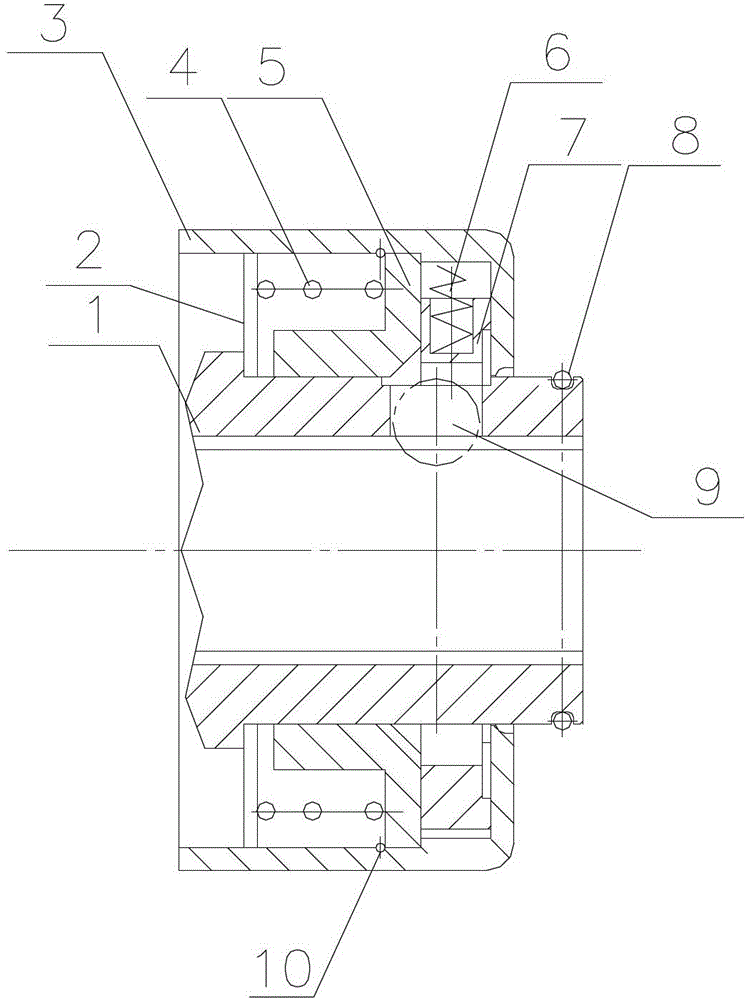

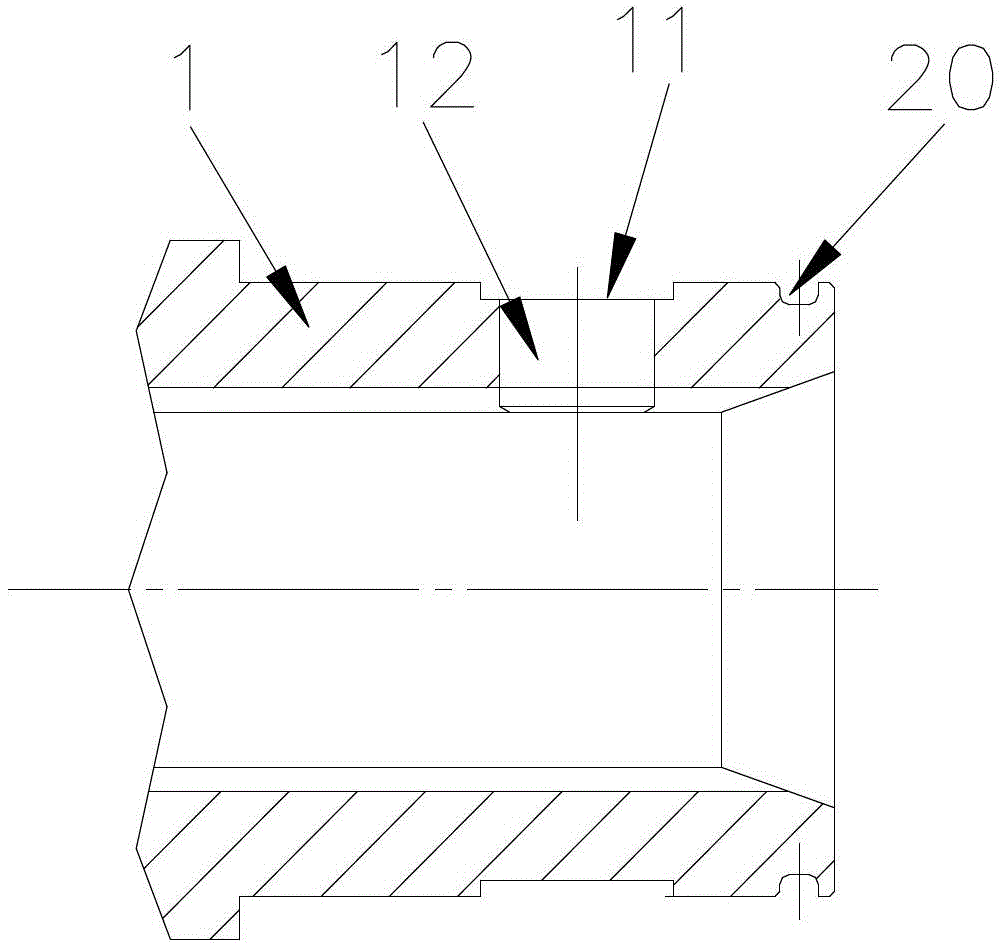

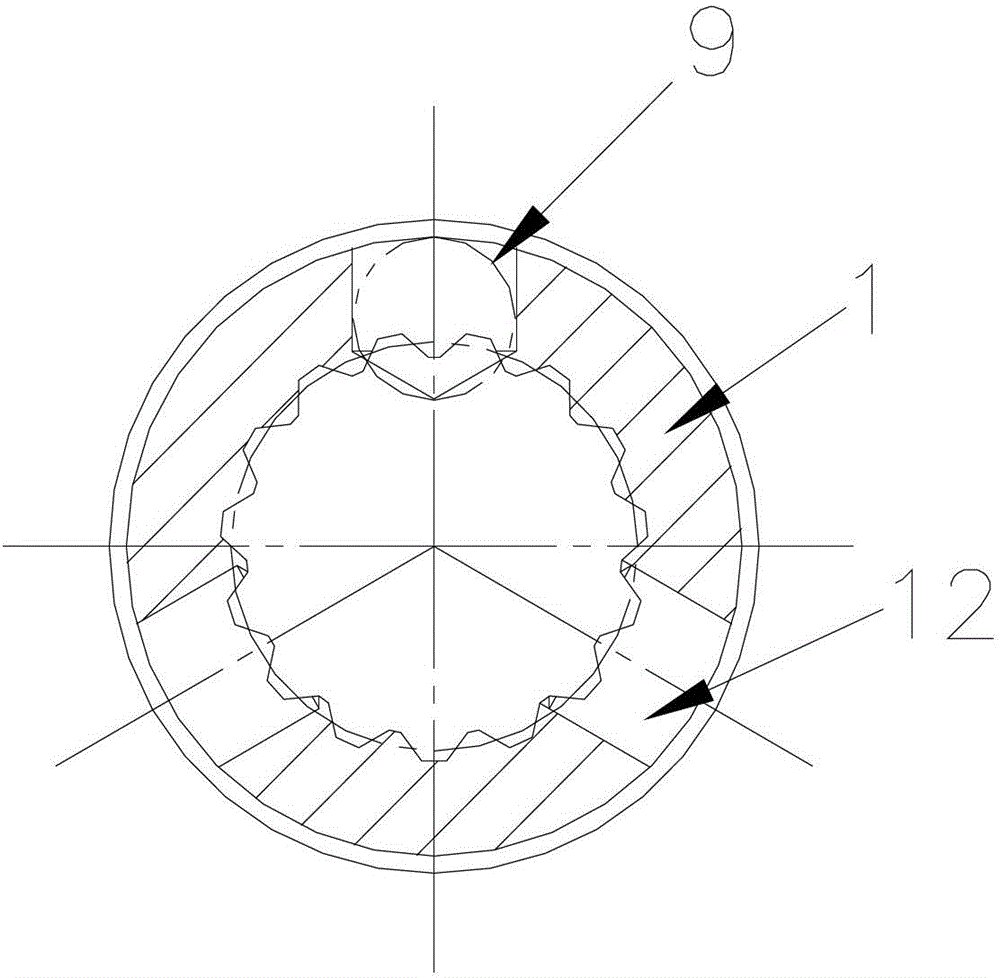

[0014] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 , 3, and 4, the present invention includes a spline connection fork 1, a sliding ring 3, and a steel ball locking block 5. The outer diameter of the spline connection fork 1 is provided with a draw-in groove 11, and the draw-in groove 11 The eccentric ring 7 is stuck; the steel ball locking block 5 is set on the spline connection fork 1, and is close to one side of the eccentric ring 7; the steel ball locking block 5 and the stop ring 2 are sandwiched The large spring 4 and the stop ring 2 are limited to the stepped groove of the splined connection fork 1, the stop ring 2 and the steel ball locking block 5 are located in the sliding ring 3, and the sliding ring 3 is sleeved on the splined connection fork 1.

[0015] The eccentric ring 7 is provided with an inner groove 71 , and the small spring 6 against the sliding ring 3 is placed in the inner groove 71 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com