A parasitic energy-saving feeding and screening integrated machine

A parasitic, all-in-one technology, applied in the field of mining machinery, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

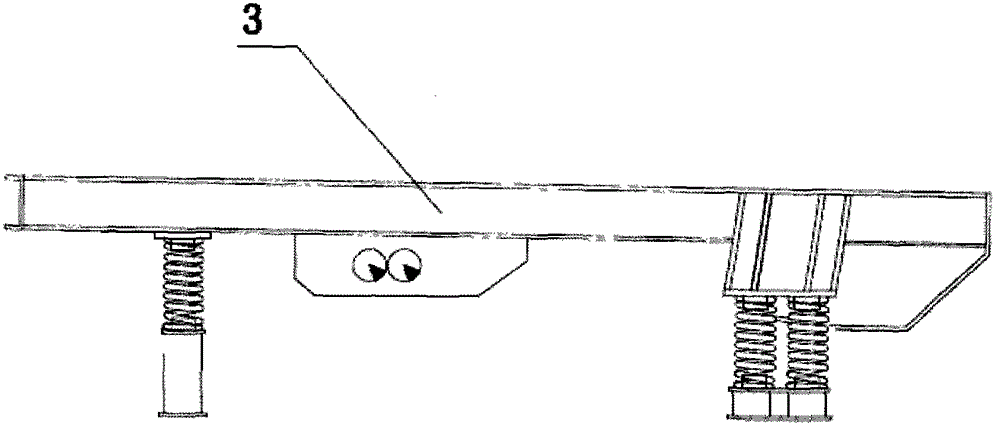

[0061] Embodiment 1: as Figure 5 , Image 6 with Figure 7 As shown, a parasitic energy-saving feeding and screening integrated machine includes a feeding box 3, a vibrating box 9, a base 1 and a stand 2, and the feeding box 3, the base 1 and the vibrating box 9 automatically Combined from top to bottom.

[0062] The base 1 is set on the platform 2 through an elastic support mechanism; the feeding box 3 is erected on the upper side of the base 1 through a support rod 4 . The vibrating box body 9 is arranged on the lower side of the base 1 , and three layers of screens 10 are arranged in the vibrating box body 9 .

[0063] The elastic support mechanism includes a spring assembly vertically supported between the base 2 and the stand 3 . The spring assembly includes two spring seats 6, the spring seat 6 further includes a spring mounting head 7 and a mounting head base 8, the spring mounting head 7 and the mounting head base 8 are hingedly connected, and a spring 5 is connec...

Embodiment 2

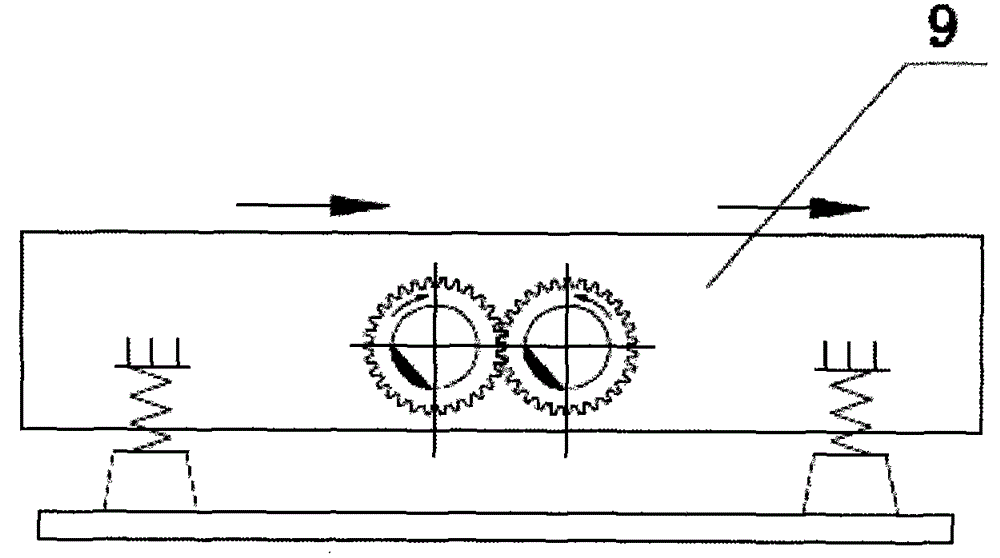

[0065] Embodiment 2: as Figure 8 with Figure 9 As shown, the base 1 is arranged on the platform 2 through an elastic support mechanism; the elastic support mechanism includes a spring assembly vertically supported between the base 1 and the platform 2 and a laterally limited spring components. The spring assembly includes two spring seats 6, the spring seat 6 further includes a spring mounting head 7 and a mounting head base 8, the spring mounting head 7 and the mounting head base 8 are hingedly connected, and a spring 5 is connected between the two spring mounting heads 7.

[0066] All the other are with embodiment 1.

Embodiment 3

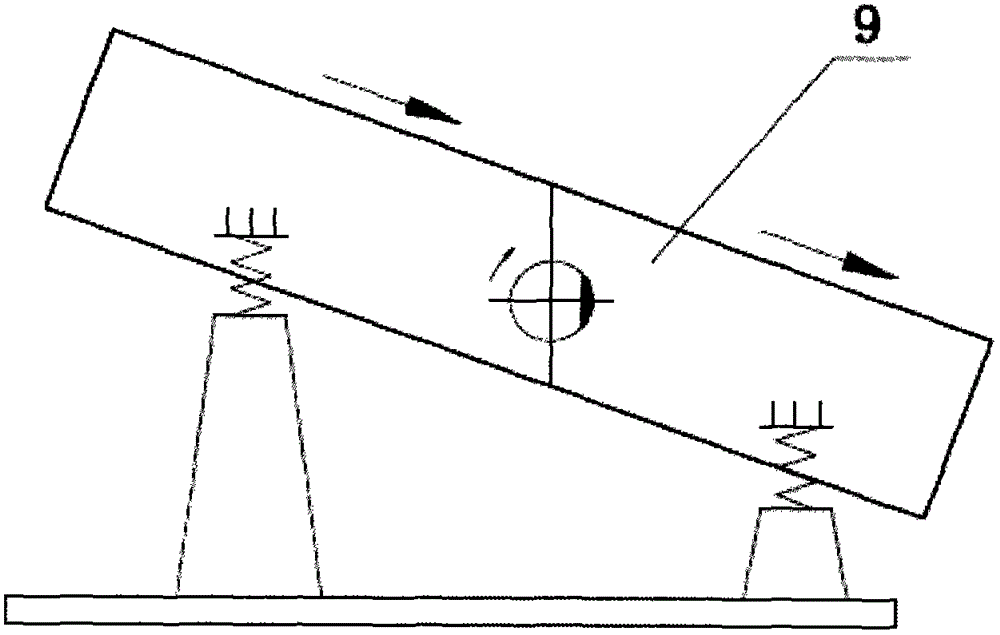

[0067] Embodiment 3: as Figure 10 As shown, the lower side of the feeding box body 3 is erected above the base 1 through a support rod 4, and the lower side of the other side is erected on the platform 2 through the support rod 4, but the support rod 4 is connected to the feeding box body 3 at this place. A spring 5 is arranged between the bottoms.

[0068] All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com