Linear compressor

A linear compressor and cylinder technology, applied in the field of compressors, can solve problems such as large axial size, achieve the effects of reducing axial size, avoiding radial displacement, and ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

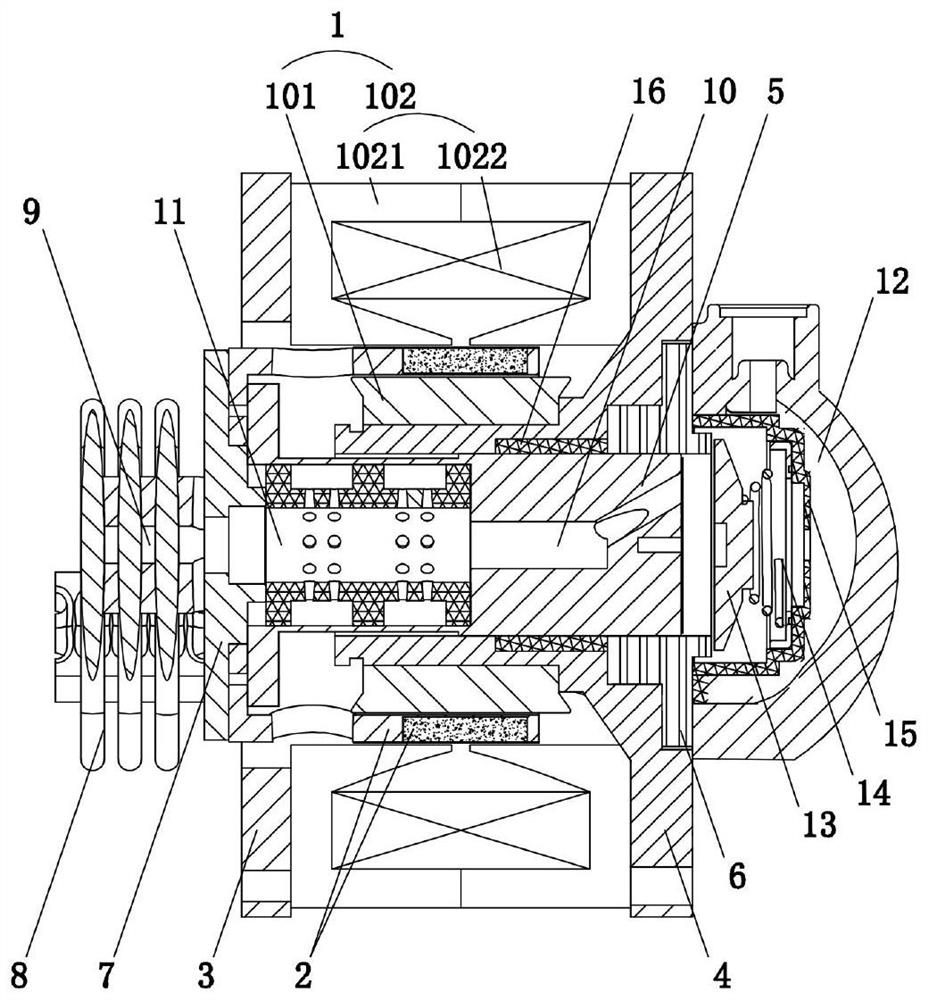

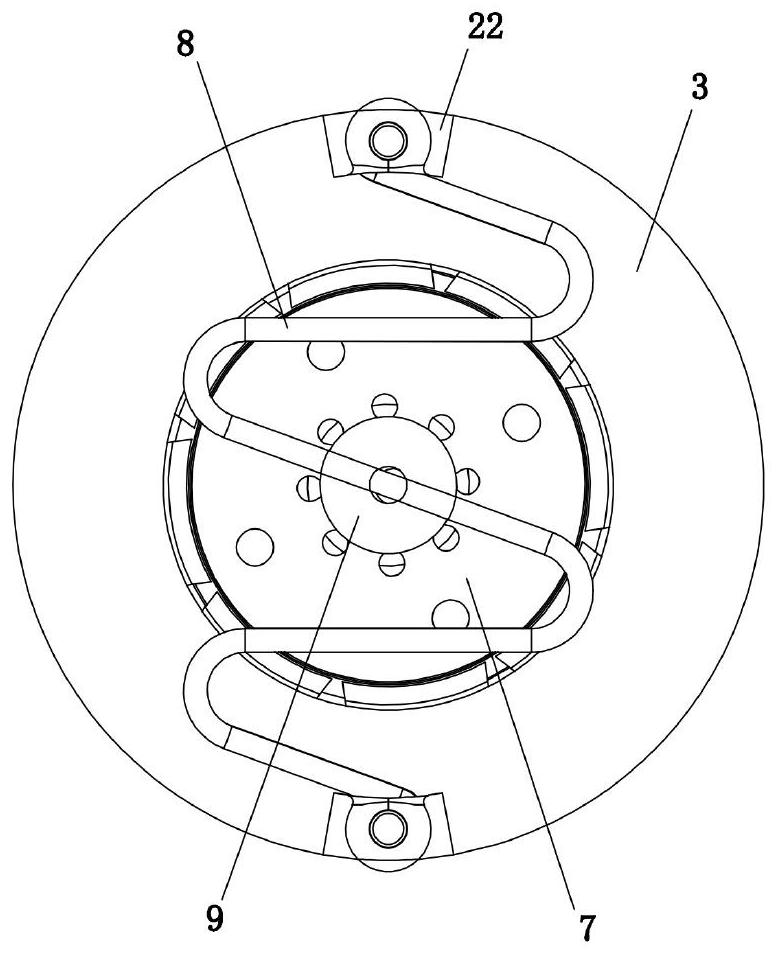

[0050] Such as figure 1 and figure 2 As shown, the stator 1 in this embodiment includes an inner stator 101 and an outer stator 102 coaxially arranged, and a cylindrical air gap is formed between the inner stator 101 and the outer stator 102; the mover 2 is embedded in the cylindrical air gap , including a coaxially connected mover skeleton and an annular permanent magnet, wherein the mover skeleton is in a cup-shaped structure; the piston 5 is coaxially located inside the mover 2, and the first end of the piston 5 is connected to the mover skeleton through a gasket 7 One end away from the annular permanent magnet, thus, the piston 5 and the mover 2 form an integral moving part.

[0051] Specifically, the first fixed seat 3 and the second fixed seat 4 are coaxially arranged at both ends of the stator 1, so that the inner stator 101, the mover 2 and the outer stator 102 are arranged in sequence in the radial direction, and the inner fixed The two ends of the sub 101 and the ...

Embodiment 2

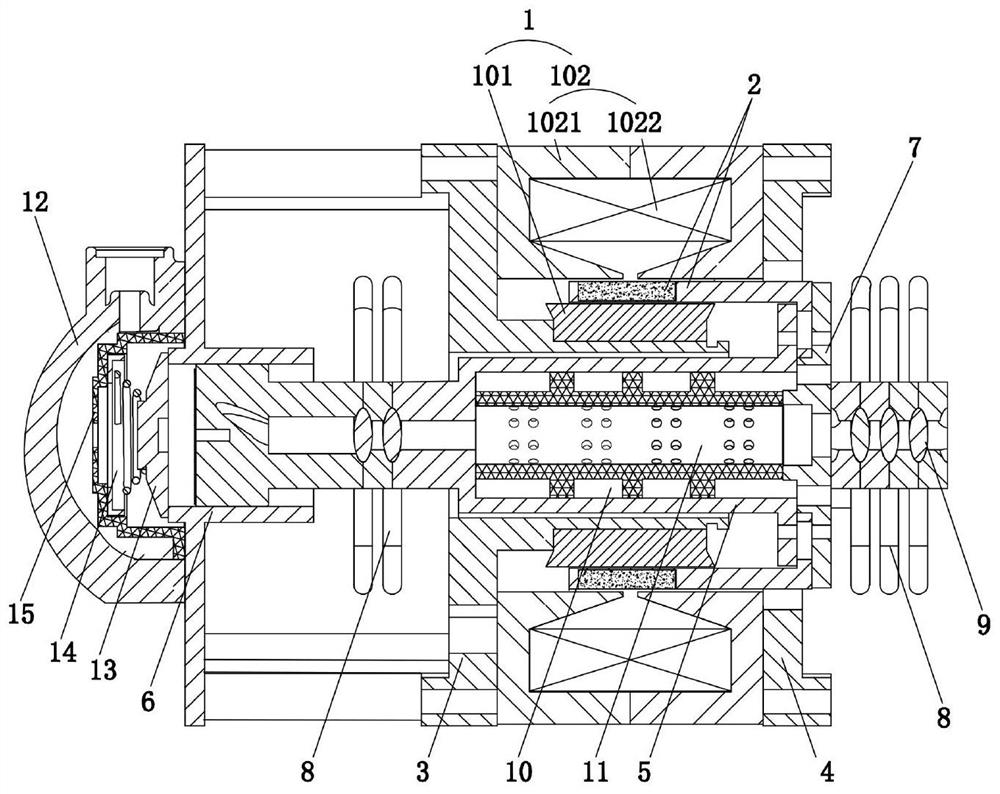

[0063] Such as image 3 As shown, this embodiment is a further improvement based on Embodiment 1. The difference is that in this embodiment, leaf spring groups 8 are provided on both sides of the stator 1, that is, the middle part of the leaf spring group 8 on the left side of the stator 1 is connected. The piston 5 on the corresponding side, the free end of the leaf spring group 8 is connected to the first fixed seat 3, the middle part of the leaf spring group 8 on the right side of the stator 1 is connected to the end of the corresponding side piston 5, the free end of the leaf spring group 8 It is connected to the second fixed seat 4 , wherein the cylinder 6 and its corresponding exhaust device can be arranged on the first fixed seat 3 or on the second fixed seat 4 , which is not specifically limited.

[0064] As a result, the two sets of leaf springs 8 jointly provide sufficient radial support for the piston 5 from both sides of the piston 5, effectively avoiding the pheno...

Embodiment 3

[0066] Such as Figure 4 As shown, this embodiment is a further improvement based on Embodiment 1, and the difference is that the gas bearing sleeve 16 shown in Embodiment 1 is not needed in the linear compressor shown in this embodiment. Since in embodiment 1, a leaf spring group 8 is provided on one side of the stator 1 to provide better radial support for the piston 5 in the process of reciprocating movement in the cylinder 6, thereby greatly reducing the size of the piston 5 and the cylinder. 6, the present embodiment can also use oil lubrication to further reduce the contact friction between the piston 5 and the cylinder 6, and ensure a longer service life of the linear compressor.

[0067] Thus, in the design of the specific scheme, the oil pump 17 and the oil injection channel 18 can be set, and the oil pump 17 and the cylinder 6 are jointly installed on the second fixed seat 4. One end of the oil injection channel 18 communicates with the oil delivery end of the oil pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com