Large-size high-density tungsten crucible and preparation method thereof

A tungsten crucible and high-density technology, which is applied in the field of large-scale high-density tungsten crucible and its preparation, can solve the problems of low crucible density, unsatisfactory development, high energy consumption, etc., and achieve low impurity content, batch production, and high density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Select Fw-1 type tungsten powder with an average Fibonacci particle size of 1.8 microns as the raw material of the tungsten crucible, and batch together in a V-type mixer for 1 hour.

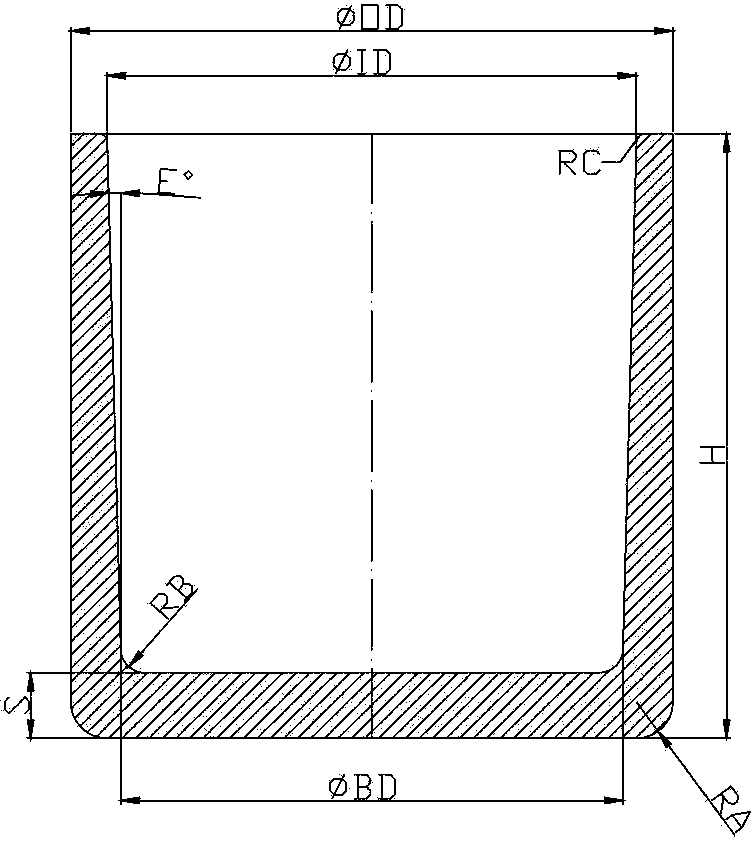

[0029] (2) According to Type tungsten crucible drawings (such as figure 1 shown) to design the crucible core.

[0030] (3) Assemble the mold core and rubber sleeve according to the required size of the green compact, put the raw materials into the sleeve, and seal it after the filling is completed. Hang the loaded mold core into the cold isostatic press cylinder and press it. The forming pressure is 220Mpa, the pressure is kept for 15 minutes, and the pressure release time is 5 minutes.

[0031] (4) The compact is sintered in a high-temperature sintering furnace, the heating rate is 80°C / h, the maximum temperature is 2200°C, and the high-temperature holding time is 6 hours.

[0032] (5) Check the appearance quality of the sintered billet without defects, and measure the sintered b...

Embodiment 2

[0035] (1) Select Fw-1 type tungsten powder with an average Fischer grain size of 4 microns as the raw material of the tungsten crucible, and batch it in a V-type mixer for 4 hours.

[0036] (2) According to Type tungsten crucible drawing design crucible core.

[0037] (3) Assemble the mold core rubber sleeve according to the required size of the green compact, put the raw materials into the sleeve, and seal it after the filling is completed. Hang the loaded mold core into the cold isostatic press cylinder and press it. The forming pressure is 270Mpa, the pressure is maintained for 50 minutes, and the pressure release time is 20 minutes.

[0038] (4) The compact is sintered in a high-temperature sintering furnace, the heating rate is 150°C / h, the maximum temperature is 2400°C, and the high-temperature holding time is 12 hours.

[0039] (5) Check the appearance quality of the sintered billet without defects, and measure the sintered billet density of the tungsten crucible wi...

Embodiment 3

[0042] (1) Select Fw-1 type tungsten powder with an average Fischer particle size of 3 microns as the raw material for the tungsten crucible, and batch together in a V-type mixer for 2 hours.

[0043] (2) According to Type tungsten crucible drawing design crucible core.

[0044] (3) Assemble the mold core and rubber sleeve according to the required size of the green compact, put the raw materials into the sleeve, and seal it after the filling is completed. Hang the loaded mold core into the cylinder of the cold isostatic press for pressing, and the forming pressure is 250Mpa. Hold the pressure for 30 minutes and release the pressure for 15 minutes.

[0045] (4) The compact is sintered in a high-temperature sintering furnace, the heating rate is 100°C / h, the maximum temperature is 2300°C, and the high-temperature holding time is 10 hours.

[0046] (5) Check the appearance quality of the sintered billet without defects, and measure the sintered billet density of the tungsten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com