Wiping base for electric coagulation forceps

A technology of electrocoagulation tweezers and cavities, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as environmental pollution, low efficiency, and unsealed waste, and achieve convenient use, The effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

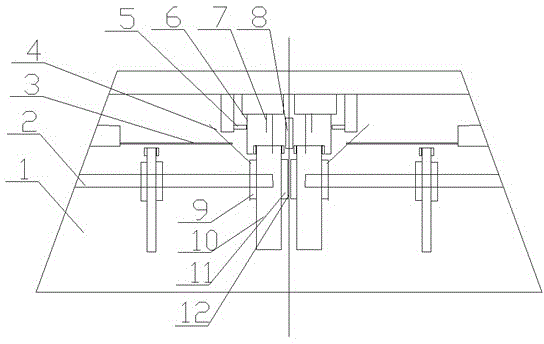

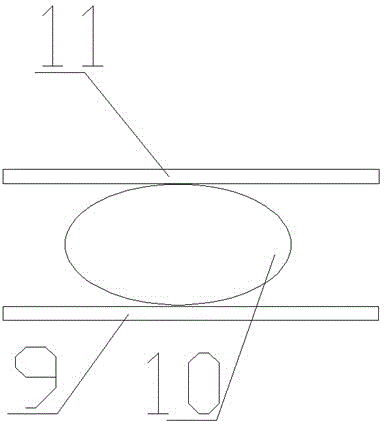

[0013] Embodiment 1: as Figure 1 to Figure 3 As shown, a kind of electric coagulation tweezers wipe base, in the base, two mutually isolated cavities 1 are arranged through the isolation plate, and two through holes for the tweezers rod to extend into are arranged on the upper surface of the base, in the through holes An inductor is also arranged on the side wall, and a draw-in groove 2 is arranged on the side wall of the cavity on each side, and a groove is also arranged on the side wall of the base at one end of the draw-in groove close to the isolation plate, and in each cavity It also includes a storage bag 10 with a first fixing piece 11 and a second fixing piece 9 inside, the storage bag itself is made of plastic material, the storage bag is an upper opening, and the upper opening part of the storage bag is folded downward, so that the storage bag has a folding Part, wherein the first fixing piece and the second fixing piece are respectively fixed on both sides of the c...

Embodiment 2

[0018] Embodiment 2: as Figure 4 As shown, the difference from Embodiment 1 is that the bottom end of the hydraulic rod 6 of the third hydraulic rod has a horizontal part and a part extending obliquely upwards, forming a fishhook shape, and such a structure can better fold the upper part of the storage bag partly extended.

Embodiment 3

[0019] Embodiment 3: Different from Embodiment 1, a cleaning tape is also provided on the inner wall of the opening of the containing bag for wiping the tweezers rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com