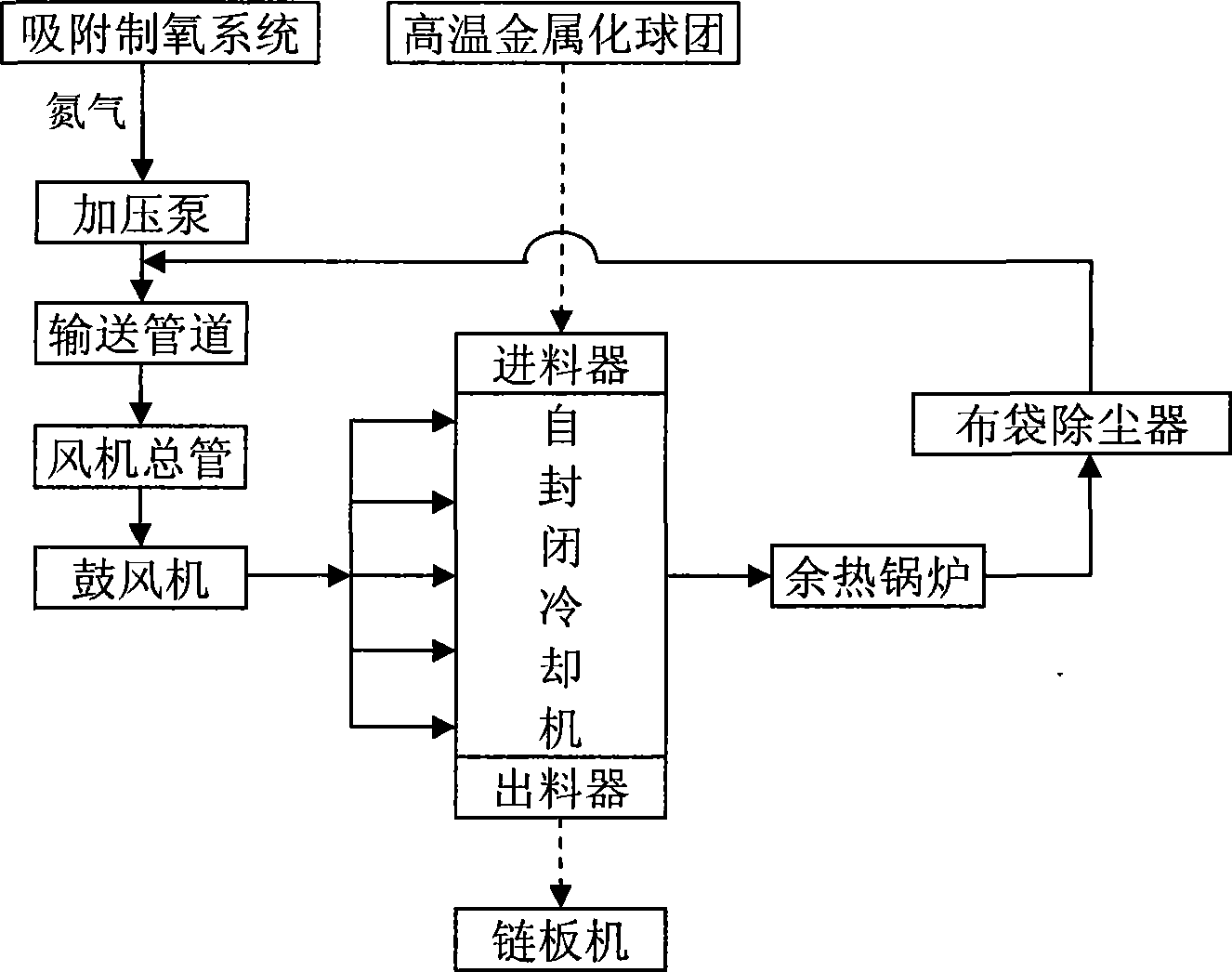

Self-sealing nitrogen circulating cooling method and apparatus

A circulating cooling and self-sealing technology, applied in the field of metallized pellet production in the iron and steel industry, can solve the problems of small temperature difference between inlet and outlet cooling water, inability to recycle waste heat, affecting the metallization rate of products, etc. Reduce, achieve the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

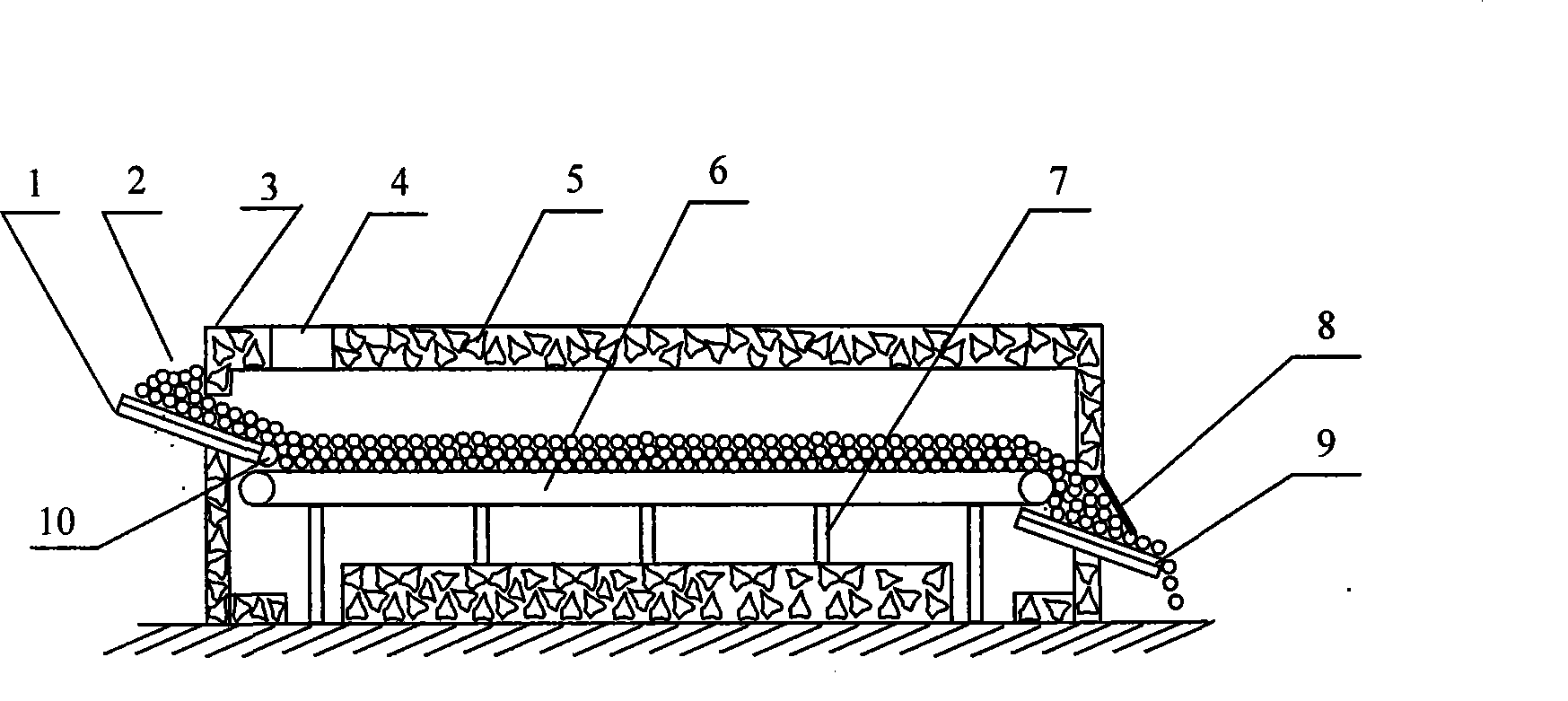

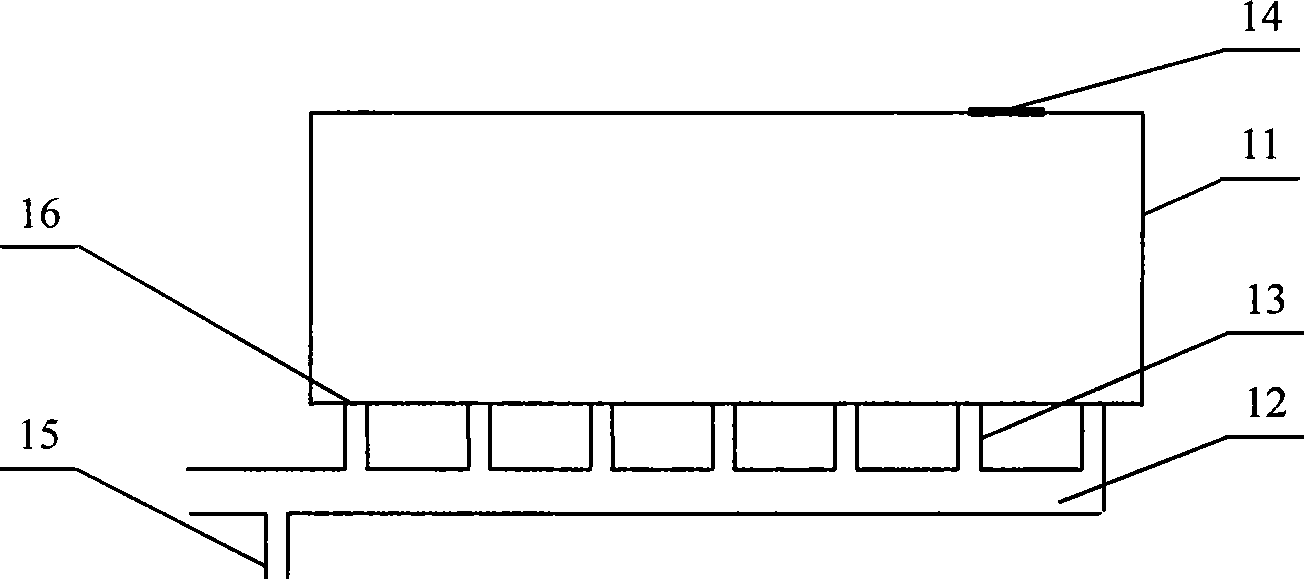

Embodiment 1

[0032] The nitrogen with a purity of 90% is discharged from the iron and steel plant after oxygen production by adsorption oxygen production technology, and the pressure pump and the pipeline are transported at a distance of 5m. 3 The air volume per hour is sent to the main pipe of the fan. After the supplementary nitrogen is mixed with the circulating gas after waste heat recovery, it is pressurized by the blower and sent to the inlet pipe of the cooler at a speed of 1.3m / s, and enters the grate inside the cooler through the side branch pipe. The 1m wide, 6m long, and 300mm high high temperature metallized pellet material layer area is output from the large flue after heat exchange with the 1000°C high temperature pellets. The temperature of the exhaust gas in the large flue is as high as 580°C. The heat recovery of the waste heat boiler produces 2.6 tons of steam per hour, and the temperature drops to 200°C. It is introduced into the fan main pipe as circulating gas and mixed...

Embodiment 2

[0035] Nitrogen gas with a purity of 80% is discharged from the iron and steel plant after oxygen production by adsorption oxygen production technology, and is sent to the fan main pipe at a gas volume of 15m3 / h through a booster pump and a delivery pipeline. After being pressurized by the blower, it is sent to the inlet pipe of the cooler at a speed of 1.3m / s, and enters the high-temperature metallized pellet material layer area of the cooler with a width of 1.5m, a length of 12m, and a height of 500mm through the side branch pipe. The 1000°C high-temperature pellets are output from the large flue after heat exchange. The temperature of the exhaust gas in the large flue is as high as 600°C. After heat recovery by the waste heat boiler, the steam volume per hour is 5.2 tons, and the temperature drops to 180°C. It is introduced into the fan main pipe as circulating gas and mixed with supplementary nitrogen for recycling.

[0036] The 1000℃ high-temperature metallized pellets ...

Embodiment 3

[0038] The nitrogen with a purity of 50% is discharged from the iron and steel plant after oxygen production by adsorption oxygen production technology, and the pressure pump and the delivery pipeline are separated by 10m 3 The air volume per hour is sent to the main pipe of the fan. After the supplementary nitrogen is mixed with the circulating gas after waste heat recovery, it is pressurized by the blower and sent to the inlet pipe of the cooler at a speed of 1.2m / s, and enters the grate inside the cooler through the side branch pipe. The 1m wide, 10m long, and 400mm high high-temperature metallized pellet layer area is output from the large flue after heat exchange with the 1000°C high-temperature pellets. The temperature of the exhaust gas in the large flue is as high as 550°C. The steam volume per hour is 3.6 tons after heat recovery by the waste heat boiler, and the temperature drops to 180°C. It is introduced into the fan main pipe as circulating gas and mixed with suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com