3D printing magnesium alloy material degradation test device and application

A 3D printing and testing device technology, applied in the field of biomedicine, can solve the problems of unintuitive results and inaccurate test results, and achieve accurate and intuitive results, convenient and fast testing, and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

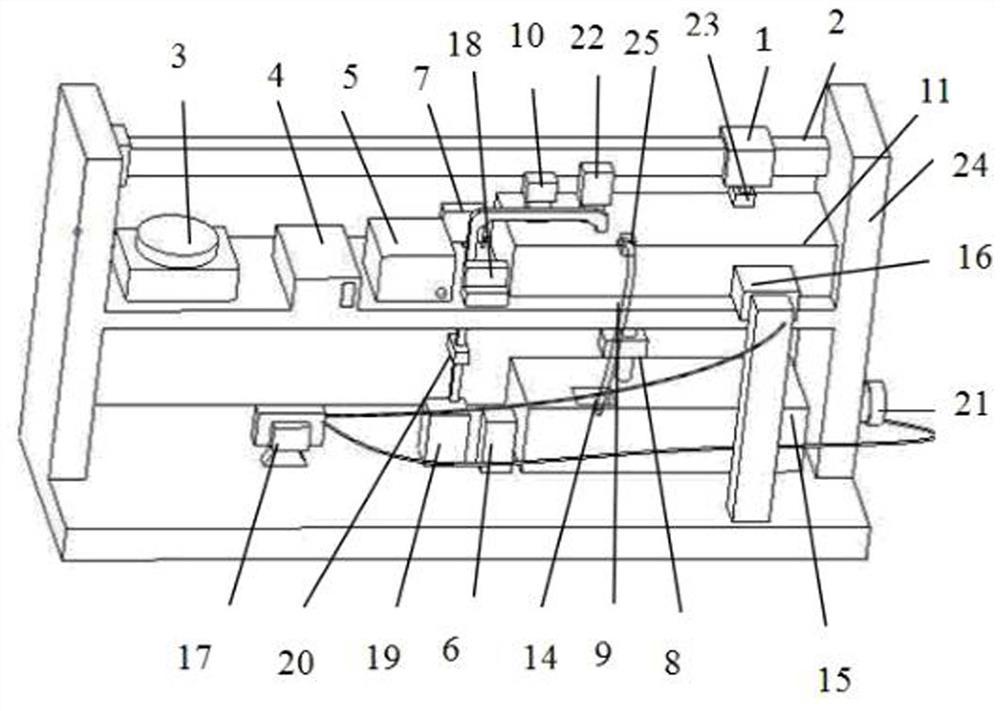

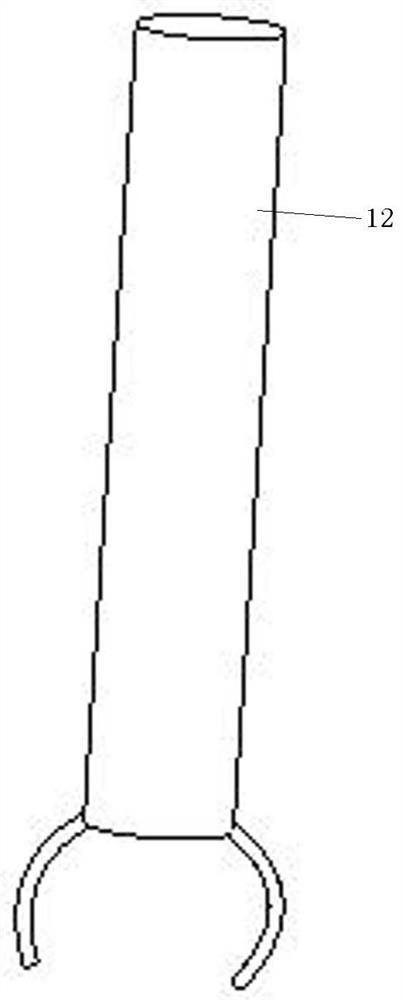

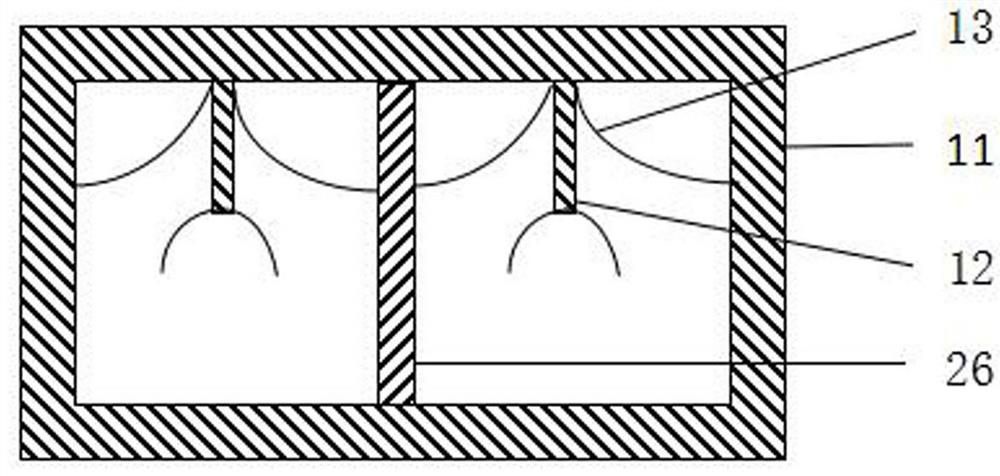

[0044] Such as figure 1 , 2 , a kind of 3D printing magnesium alloy biomaterial degradability test device shown in 3, comprises the cardiac bionic cabin 11, sample loading device, pretreatment device fixed on the support 24; The internal middle position of described cardiac bionic cabin 11 is fixed There is a non-porous bionic valve plate 26, and the non-porous bionic valve plate 26 divides the heart bionic cabin 11 into two independent areas that are not connected to each other on the left and right sides. In the heart bionic cabin on both sides of the non-porous bionic valve plate 26, porous bionic valves are respectively arranged. The valve plate 13 is provided with outlets on both sides of the bottom of the bionic heart chamber 11, and the outside is connected to the liquid storage tank 15 through two power pumps 14 and the liquid supply pipeline 9 equipped with a flow meter 8 and a high-precision flow node 25 , the liquid storage tank 15 is connected to the temperature c...

Embodiment 2

[0056] Such as figure 1 , 2 , a kind of 3D printing magnesium alloy biomaterial degradability test device shown in 3, comprises the cardiac bionic cabin 11, sample loading device, pretreatment device fixed on the support 24; The internal middle position of described cardiac bionic cabin 11 is fixed There is a non-porous bionic valve plate 26, and the non-porous bionic valve plate 26 divides the heart bionic cabin 11 into two independent areas that are not connected to each other on the left and right sides. In the heart bionic cabin on both sides of the non-porous bionic valve plate 26, porous bionic valves are respectively arranged. The valve plate 13 is provided with outlets on both sides of the bottom of the bionic heart chamber 11, and the outside is connected to the liquid storage tank 15 through two power pumps 14 and the liquid supply pipeline 9 equipped with a flow meter 8 and a high-precision flow node 25 , the liquid storage tank 15 is connected to the temperature c...

Embodiment 3

[0068] Such as figure 1 , 2 , a 3D printing magnesium alloy biomaterial degradability test device shown in 3, including fixed on a support such as figure 1 , 2 , a kind of 3D printing magnesium alloy biomaterial degradability test device shown in 3, comprises the cardiac bionic cabin 11, sample loading device, pretreatment device fixed on the support 24; The internal middle position of described cardiac bionic cabin 11 is fixed There is a non-porous bionic valve plate 26, and the non-porous bionic valve plate 26 divides the heart bionic cabin 11 into two independent areas that are not connected to each other on the left and right sides. In the heart bionic cabin on both sides of the non-porous bionic valve plate 26, porous bionic valves are respectively arranged. The valve plate 13 is provided with outlets on both sides of the bottom of the bionic heart chamber 11, and the outside is connected to the liquid storage tank 15 through two power pumps 14 and the liquid supply pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com