High-speed steel for high-toughness high-abrasion resistance hobbing cutter and preparation method thereof

A high-speed steel and high wear-resistant technology, which is applied in the field of high-speed steel for high-toughness and high-wear-resistant hobs and its preparation, can solve the problems of high cost, reduced gap between cutting speed and cutting life, etc., to achieve improved wear resistance, Effect of improving grindability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

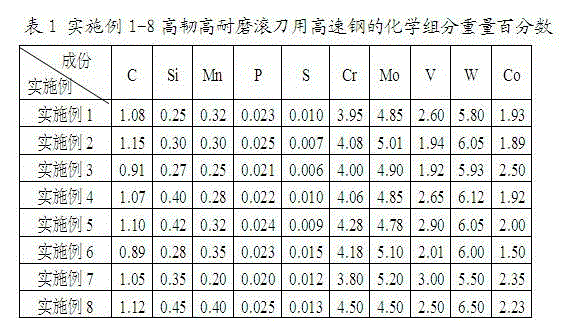

[0033] A high-toughness and high-wear-resistant high-speed steel for hobs, which consists of the following chemical components in weight percentages:

[0034] C: 1.08, Si: 0.25, Cr: 3.95, Mo: 4.85, V: 2.60, W: 5.80, Co: 1.93, Mn: 0.32, P≤0.03, S≤0.01, the balance is iron and impurities.

[0035] The preparation method of the above-mentioned high-toughness and high-wear-resistance high-speed steel for hobs is carried out according to the following steps:

[0036] (1) The high-toughness and high-resistance hob grinding high-speed steel containing the above chemical components is prepared into electroslag steel ingots by means of intermediate frequency smelting + external refining + vacuum degassing + electroslag remelting; among them, external refining and desulfurization When the molten steel is stirred with an inert gas in a vacuum state; the refining outside the furnace is desulfurized to a sulfur content S≤0.015, and the molten steel is stirred with an inert gas in a vacuum ...

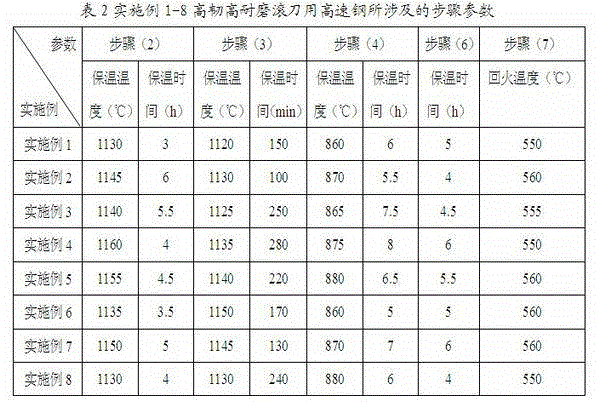

Embodiment 2-8

[0045] The high-toughness and high-wear-resistant high-speed steel for hobs involved in Examples 2-8, the weight percentage of its chemical composition is shown in Table 1, and it is prepared by the corresponding preparation method of the embodiment, and the step parameters involved As shown in Table 2, the corresponding performance test situation of each embodiment is as shown in Table 3:

[0046]

[0047]

[0048]

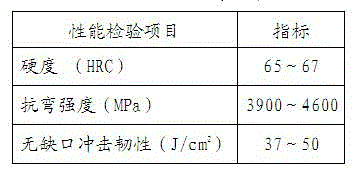

[0049] According to the national standard GB / T230, GB / T14452, GB / T229 and other standards, as shown in the table below:

[0050]

[0051] Therefore, it can be seen from Table 3 that the hardness, flexural strength and impact toughness of the high-toughness and high-wear-resistant high-speed steel for hobs all meet the national standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com