Super-hydrophobic coating layer used for oil-water separation and having hierarchical structure, super-hydrophobic material thereof, and preparation method of material

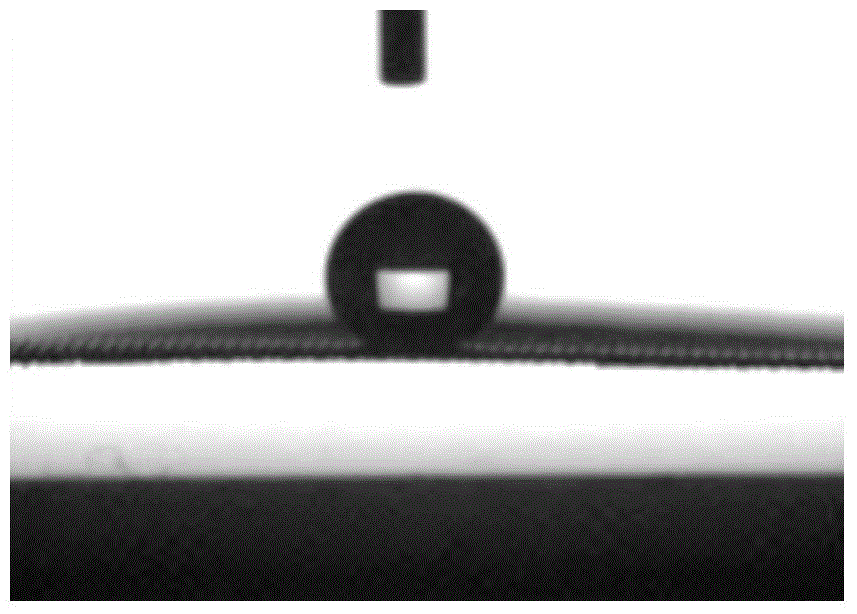

A technology of super-hydrophobic coating and rough structure, applied in the direction of coating, layered products, devices for coating liquid on the surface, etc., can solve the problems of uneven pore size, difficult separation, high cost and pollution, and achieve water contact Increased angle, good separation effect, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

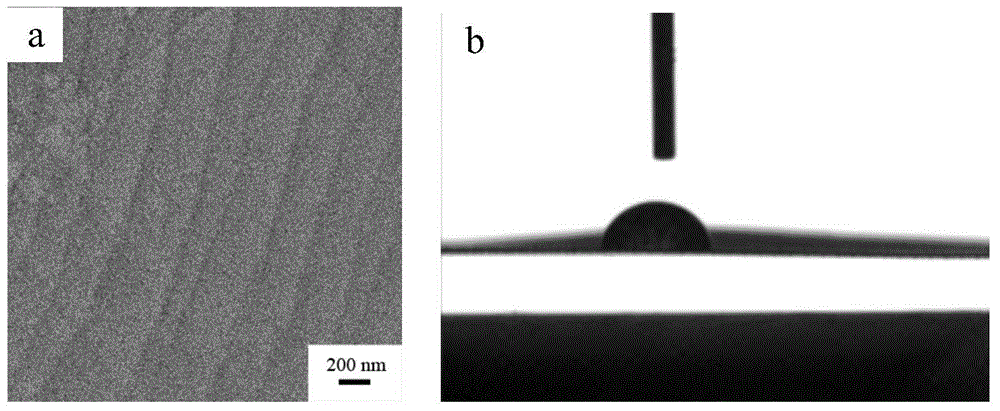

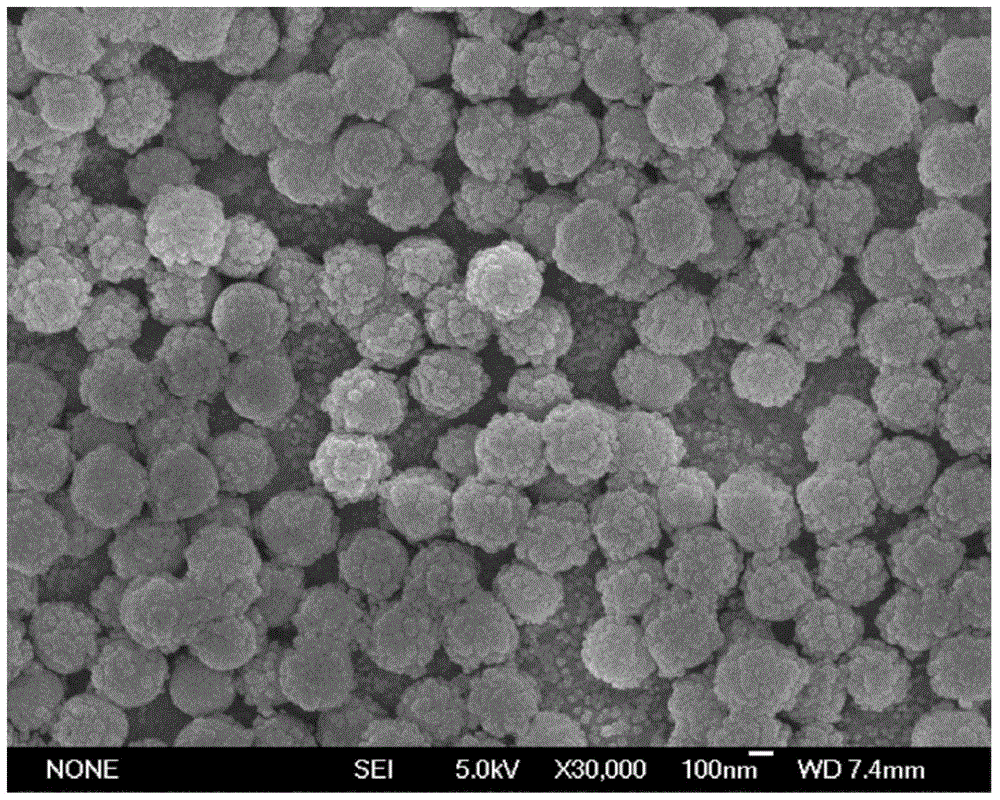

[0072] The coating consists of three layers of SiO with a particle size of 70nm and a layer of 10nm 2 Spherical nano particle layer, its preparation method comprises the following steps:

[0073] (1) Add 5mL of ammonia water and 50-150mL of absolute ethanol into the Erlenmeyer flask at room temperature and stir for 8-12 minutes, then stir for 1-3 minutes at 70 degrees Celsius, and add 5mL of tetraethyl orthosilicate (TEOS) dropwise under stirring. Stir vigorously at 70 degrees Celsius for 10-14 hours to obtain a translucent suspension containing SiO with a diameter of about 10 nm. 2 Spherical nanoparticle suspension, and dilute it into a suspension with a mass fraction of 0.1-5% for later use; add 7.5mL ammonia water and 50-150mL absolute ethanol into a conical flask and stir at room temperature for 8-12 minutes, then stir at 60 degrees Celsius for 1- For 3 minutes, add 3 mL of tetraethyl orthosilicate (TEOS) dropwise under stirring, and vigorously stir at 60 degrees Celsius ...

Embodiment 2

[0081] The coating consists of three layers of 250nm particle size and a layer of 20nm SiO 2 Nano particle layer composition, its preparation method comprises the following steps:

[0082] (1) Add 5mL of ammonia water and 50-150mL of absolute ethanol into the Erlenmeyer flask at room temperature and stir for 8-12 minutes, then stir at 60 degrees Celsius for 1-3 minutes, add 5mL of tetraethyl orthosilicate (TEOS) dropwise under stirring, and Stir vigorously at 60°C for 10-14 hours to obtain a translucent suspension containing SiO with a diameter of about 20nm 2 Spherical nanoparticle suspension, and dilute it into a suspension with a mass fraction of 0.1-5% for later use; add 5mL ammonia water, 50-150mL absolute ethanol and 1mL deionized water into the Erlenmeyer flask at room temperature and stir for 8-12 minutes, at 30 Stir for 1-3 minutes at °C, add 3 mL of tetraethyl orthosilicate (TEOS) dropwise under stirring, and stir vigorously at 30 °C for 10-14 hours to obtain a tran...

Embodiment 3

[0093] The coating consists of a layer of 250nm and a layer of 20nm SiO 2 Nano particle layer composition, its preparation method comprises the following steps:

[0094] (1) Add 5mL of ammonia water and 50-150mL of absolute ethanol into the Erlenmeyer flask at room temperature and stir for 8-12 minutes, then stir at 60 degrees Celsius for 1-3 minutes, add 5mL of tetraethyl orthosilicate (TEOS) dropwise under stirring, and Stir vigorously at 60°C for 10-14 hours to obtain a translucent suspension containing SiO with a diameter of about 20nm 2 Spherical nanoparticle suspension, and dilute it into a suspension with a mass fraction of 0.1-5% for later use; add 5mL ammonia water, 50-150mL absolute ethanol and 1mL deionized water into the Erlenmeyer flask at room temperature and stir for 8-12 minutes, at 30 Stir for 1-3 minutes at °C, add 3 mL of tetraethyl orthosilicate (TEOS) dropwise under stirring, and stir vigorously at 30 °C for 10-14 hours to obtain a translucent suspension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com