Soil-layer broaching bit

A technology for reaming drill bits and soil layers, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., which can solve the problems of small reaming diameter, easy accumulation of cut soil, and easy jamming of drill bits, etc., and achieve large reaming diameter , Simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

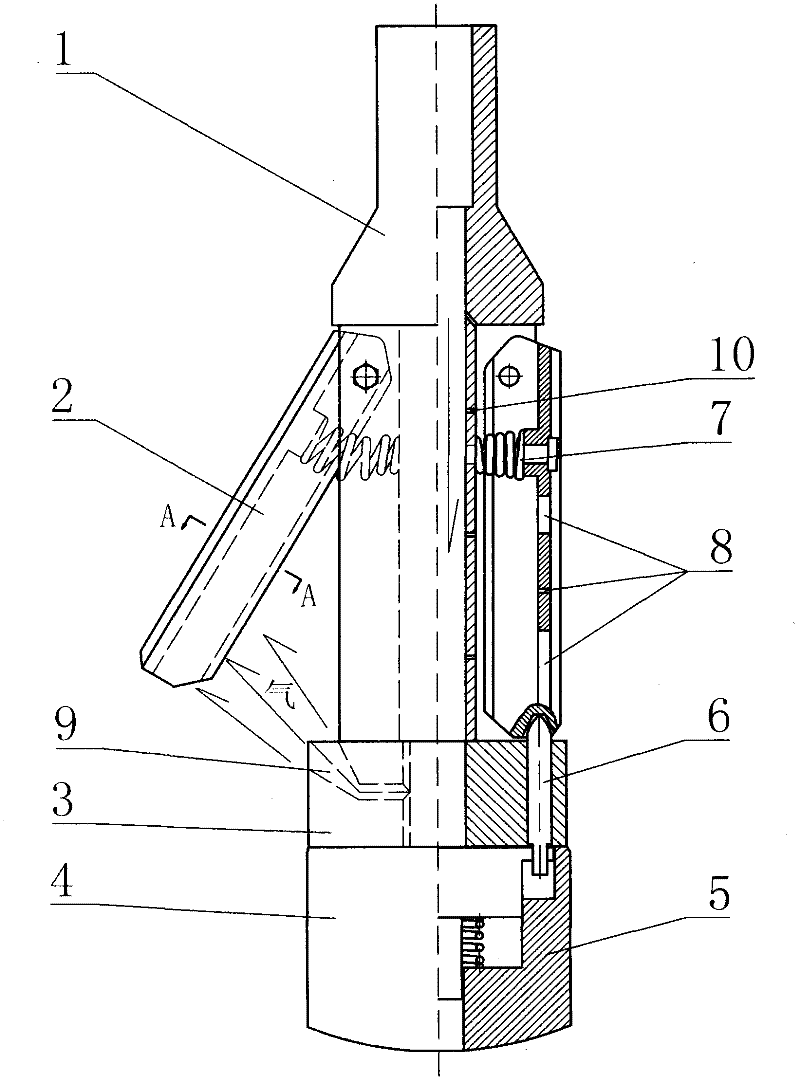

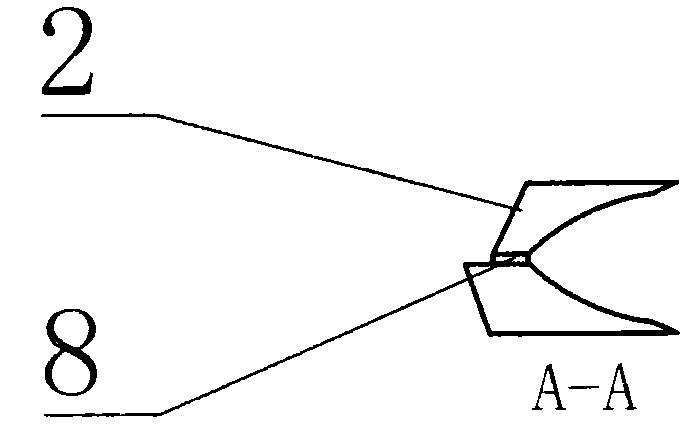

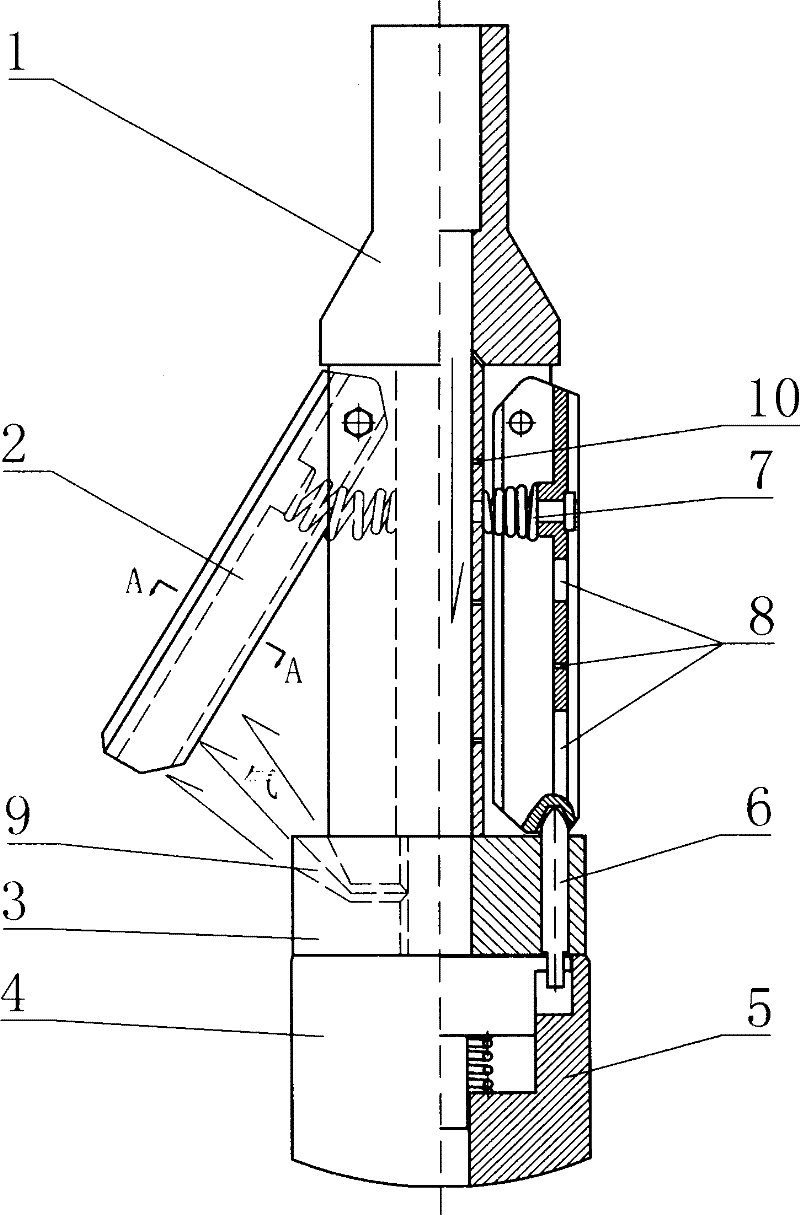

[0011] The soil expansion drill bit of the present invention comprises a base 1, a blade 2 provided outside the base 1, an air flow distributor 3 connected to the lower part of the base 1, a drill head 4 connected to the lower part of the air distributor 3, and a drill head 4 The piston 5 provided inside, the bayonet pin 6 connected to the upper end of the piston 5, and the two ends are respectively connected to the expansion spring 7 of the base 1 and the blade 2. The air pipe inside the base 1 corresponds to the air hole 10 on the tube wall of the blade 2. The airflow hole 8, the airflow hole 9 provided inside the airflow distributor 3. During actual operation, the blade 2 of the soil layer reaming drill bit of the present invention is in a closed state, that is figure 1 In the state of the middle right blade 2, the upper part of the base 1 is connected to the drill pipe. When the drill bit goes down to the working depth, the air flow in the drill bit is increased. The air f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com