Technological process for preparing durene with reformed C10 aromatic

A technology of durene and process methods, which is applied in the chemical industry, isomerization hydrocarbon production, sustainable manufacturing/processing, etc., and can solve problems such as failure to meet the needs of downstream devices, adverse effects of downstream manufacturers, and unstable product quality. , to achieve the effect of improving the production environment, high product yield and reducing emissions

Inactive Publication Date: 2008-10-08

天津市兴源化工有限公司

View PDF1 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Second, the freezing temperature required in the production of durene is low, for example, to reach -35°C, and the energy consumption is very high

Third, the purity of the product is low, generally 93-

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

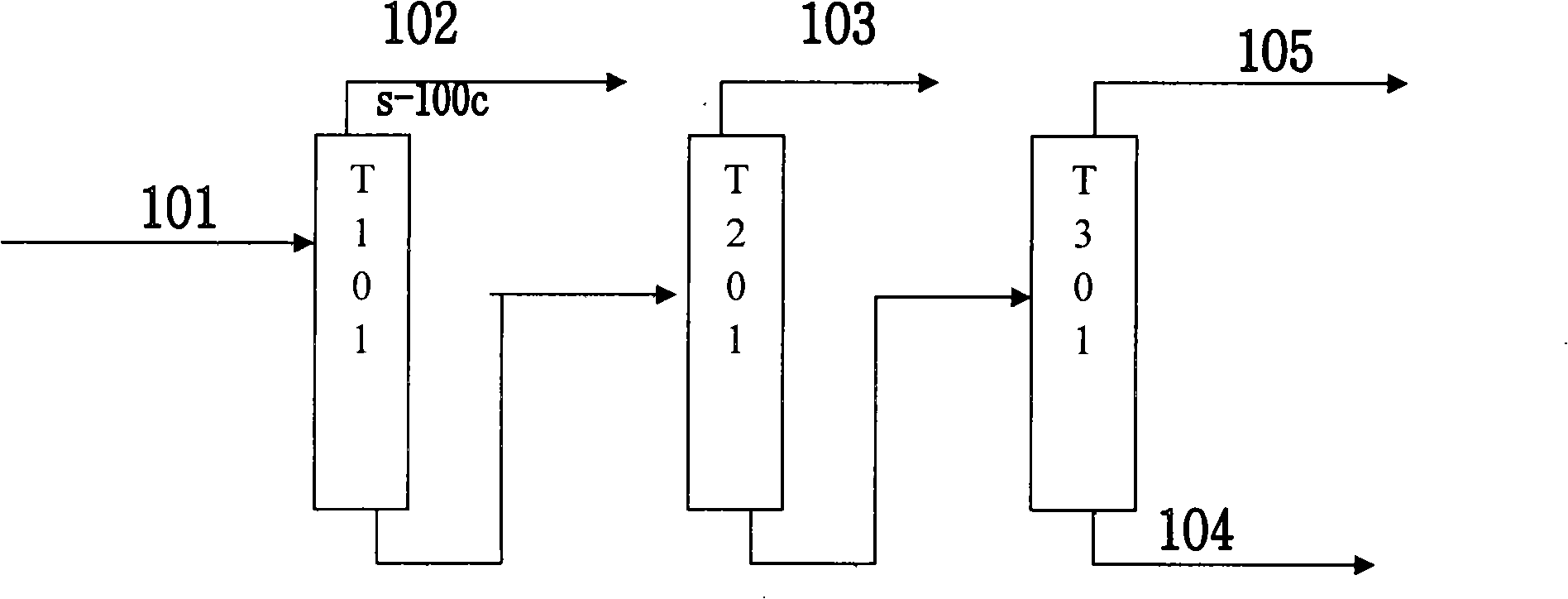

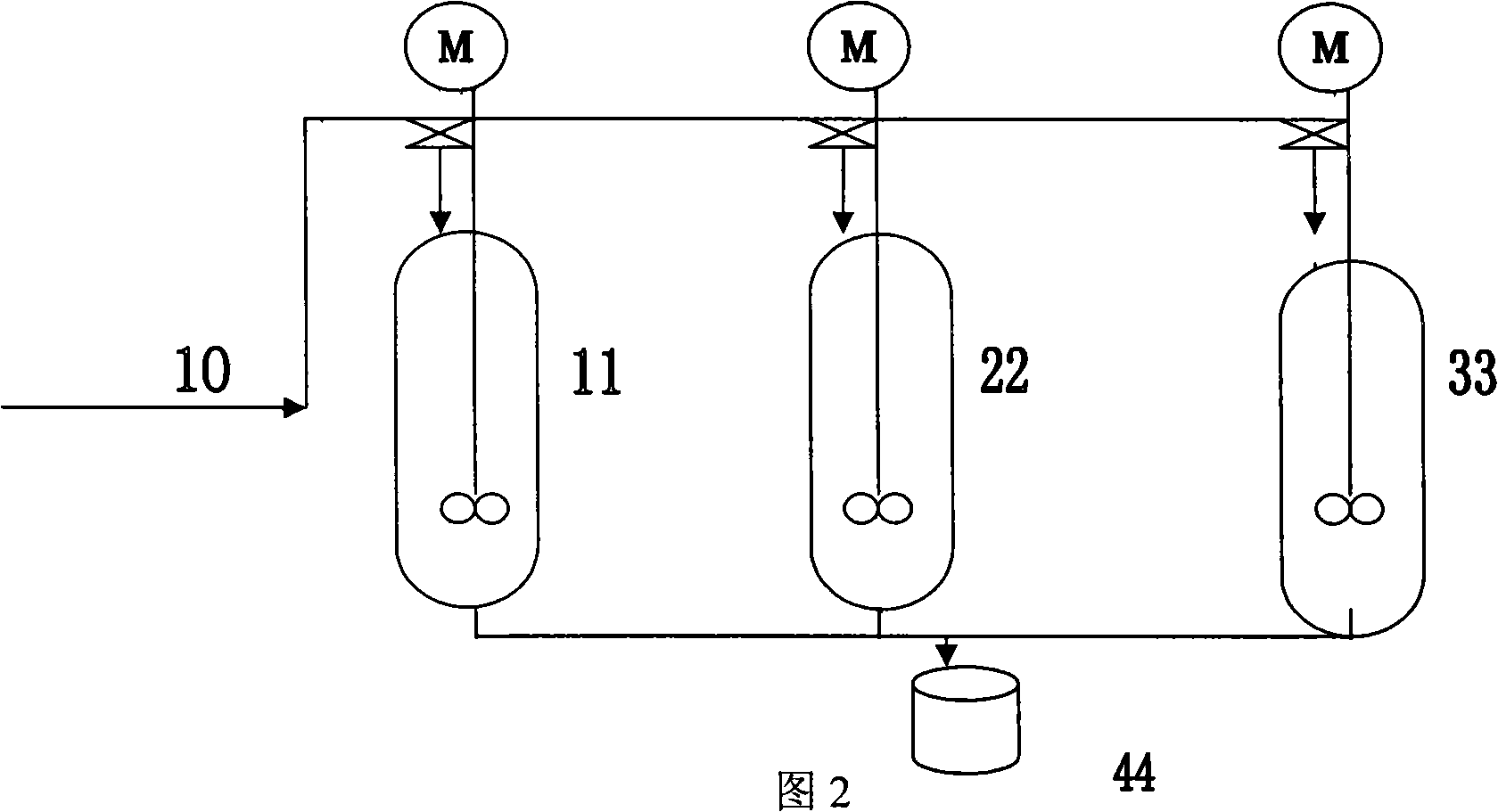

The invention relates to a technique for reforming a C10 arene to produce a durene, the reforming to the C10 arene undergoes steps of continuous rectification, freezing crystallization and separation by three rectification towers for separating out the durene front low-boiling fraction, rectifying out the durene liquid rich mother liquor and then extracting out the product before 205 DEG C by rectification; and the durene rich mother liquor is cooled to the temperature of between -5 and -10 DEG C through a refrigerating kettle, the durene in the rich liquid is saturated and separated out of a crystalline solid, and a solid durene product is obtained through fractional crystallization and pressure filtration. The product of the invention has the yield reaching 80 percent and the purity reaching 99 percent; and the technique is environment-friendly and energy-saving and will not produce smoke gas by applying the coal gas produced by itself. The technique has advantages of reducing the amount of freezing materials, increasing the freezing temperature and obviously saving the power, and has broad application prospect.

Description

technical field [0001] The invention relates to a method for extracting durene from aromatic hydrocarbons, in particular to a process for producing durene by reforming carbon ten aromatic hydrocarbons, specifically a process for producing durene by three-tower continuous rectification, freezing crystallization and separation. Background technique [0002] Durene (1,2,4,5-tetramethylbenzene) is an important organic chemical raw material. It is mainly used in China to produce pyromellitic dianhydride (referred to as homoanhydride or PMDA). PMDA is a synthetic polymer An important raw material for imide polymers. The production of durene in my country is still in the development stage, the main technologies are: C 10 Heavy aromatics crystallization separation method, trimethylbenzene methanol alkylation method, trimethylbenzene chloromethylation method, trimethylbenzene gas phase isomerization disproportionation method, etc. The heavy aromatics crystallization and separation ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C15/02C07C5/29C07C7/04

CPCY02P20/10

Inventor 乔元东刘玉江刘呈喜

Owner 天津市兴源化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com