Method and device for extracting durene from methanol synthetic oil

A methanol synthetic oil and durene technology, applied in the field of rectification, can solve the problems of complex synthetic oil components and high energy consumption, and achieve the effects of improving market competitiveness, reducing process energy consumption, and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

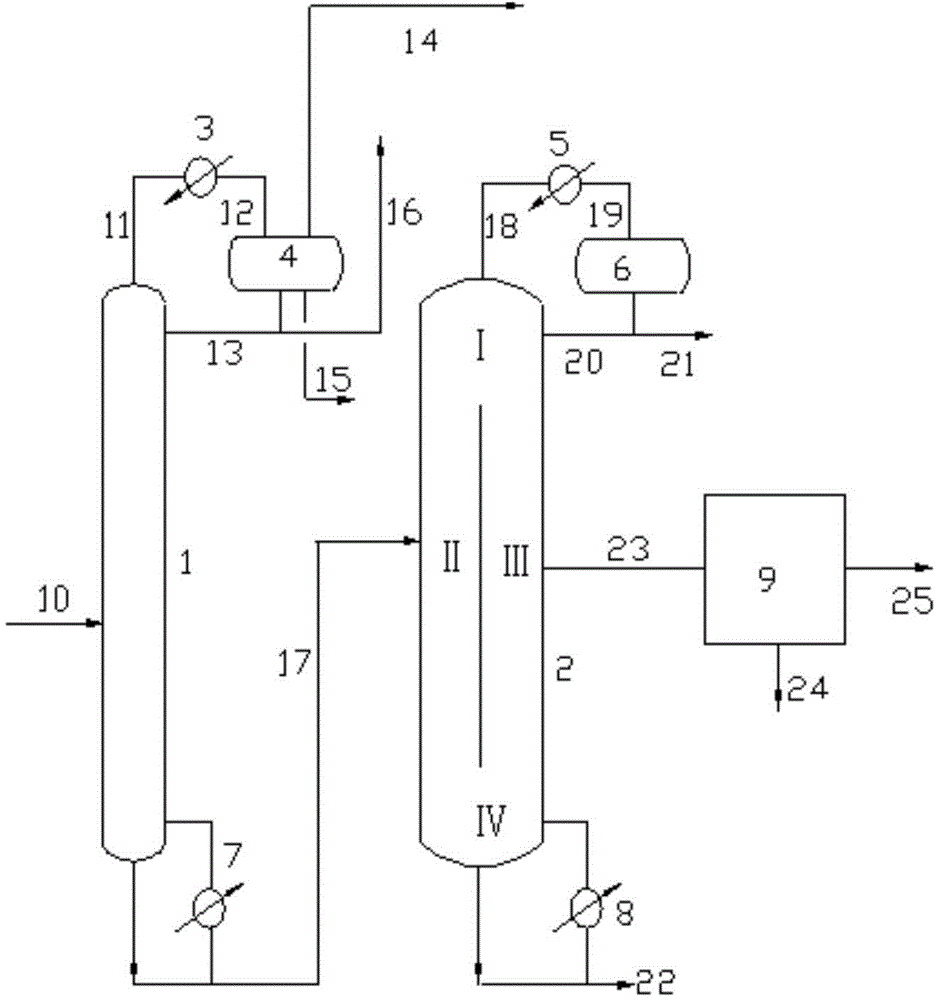

[0023] The processing capacity of the raw material methanol synthetic oil is 30 tons / hour, and the mass content of durene is 2%. The pressure at the top of the fractionation tower (1) is 100kPa, and the temperature is 70°C; the pressure at the top of the dividing wall tower (2) is 2kPa, and the temperature is 30°C; the operating temperature of the crystallization system (9) is -20°C, and the remaining crystallization mother liquor (24) is directly extracted Do not return to the next tower.

[0024] The durene obtained by the method is 0.6 tons / hour, the purity is 99.9%, the durene product yield is 99.9%, and the energy consumption is saved by about 30% compared with the conventional process.

Embodiment 2

[0025] Embodiment 2: the present invention can also be realized through the following technical solutions:

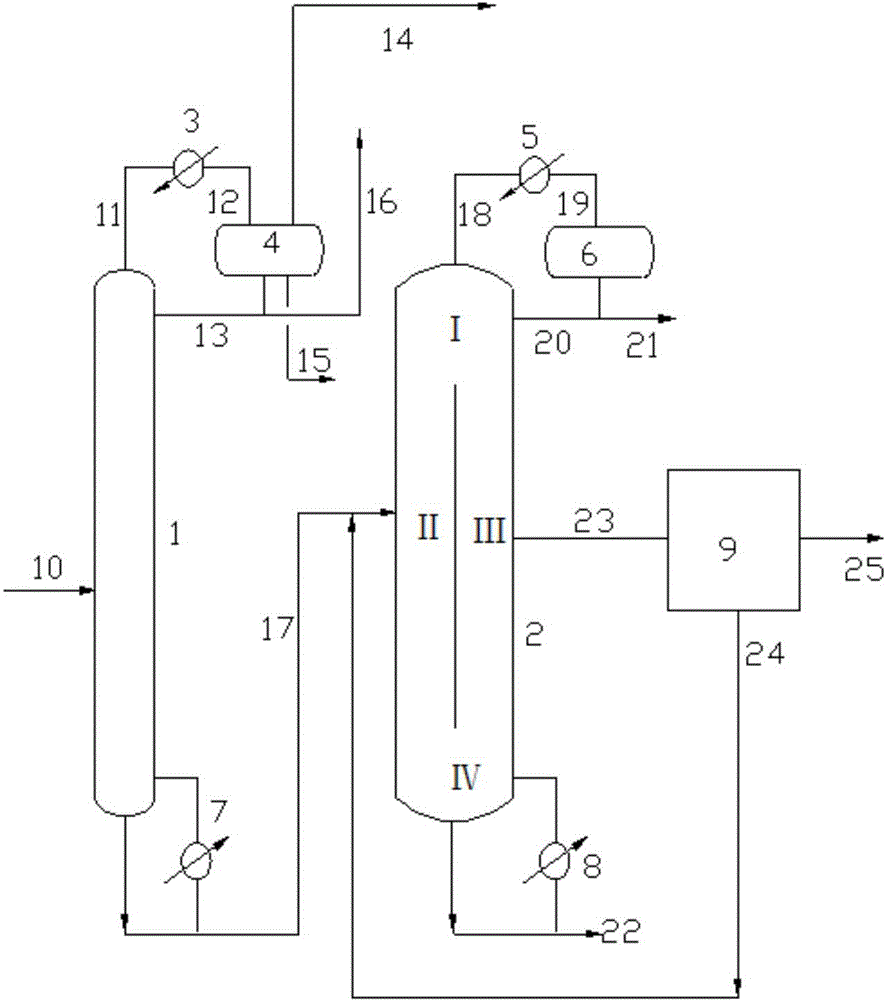

[0026] The processing capacity of the raw material methanol synthetic oil is 30 tons / hour, and the mass content of durene is 10%. Fractionation tower (1) tower top pressure is 300kPa, and temperature is 180 DEG C; Dividing wall tower (2) tower top pressure is 300kPa, and temperature is 180 DEG C; Crystallization system (9) operating temperature is 95 DEG C, remaining crystallization mother liquor (24) returns to the next wall tower, Such as figure 2 shown.

[0027] The durene obtained by the method is 2.3 tons / hour, the purity is 95%, and the yield of the durene product is 91.0%, and the energy consumption is saved by about 10% compared with the conventional process.

Embodiment 3

[0028] Embodiment 3: the present invention can also be realized through the following technical solutions:

[0029] The processing capacity of raw material methanol synthetic oil is 30 tons / hour, and the mass content of durene is 20%. Fractionation tower (1) tower top pressure is 200kPa, temperature 100 ℃; Dividing wall tower (2) tower top pressure 100kPa, temperature 200 ℃; Crystallization system (9) operating temperature is 40 ℃, remaining crystallization mother liquor (24) partly returns the dividing wall tower ,Such as figure 2 shown.

[0030] The durene obtained by the method is 9.9 tons / hour, the purity is 60%, and the yield of the durene product is 94.9%. Compared with the conventional process, the energy consumption is saved by about 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com