Process for joint production of aromatic solvent, stone oil naphthalin and durene line products with C10 heavy aromatic raw material

A technology of mesitylene and aromatic hydrocarbon solvent is applied in the field of comprehensive utilization of C10 heavy aromatics, which can solve the problems of high product price, difficult to control production cost, low resource utilization rate, etc., and achieve the effect of saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

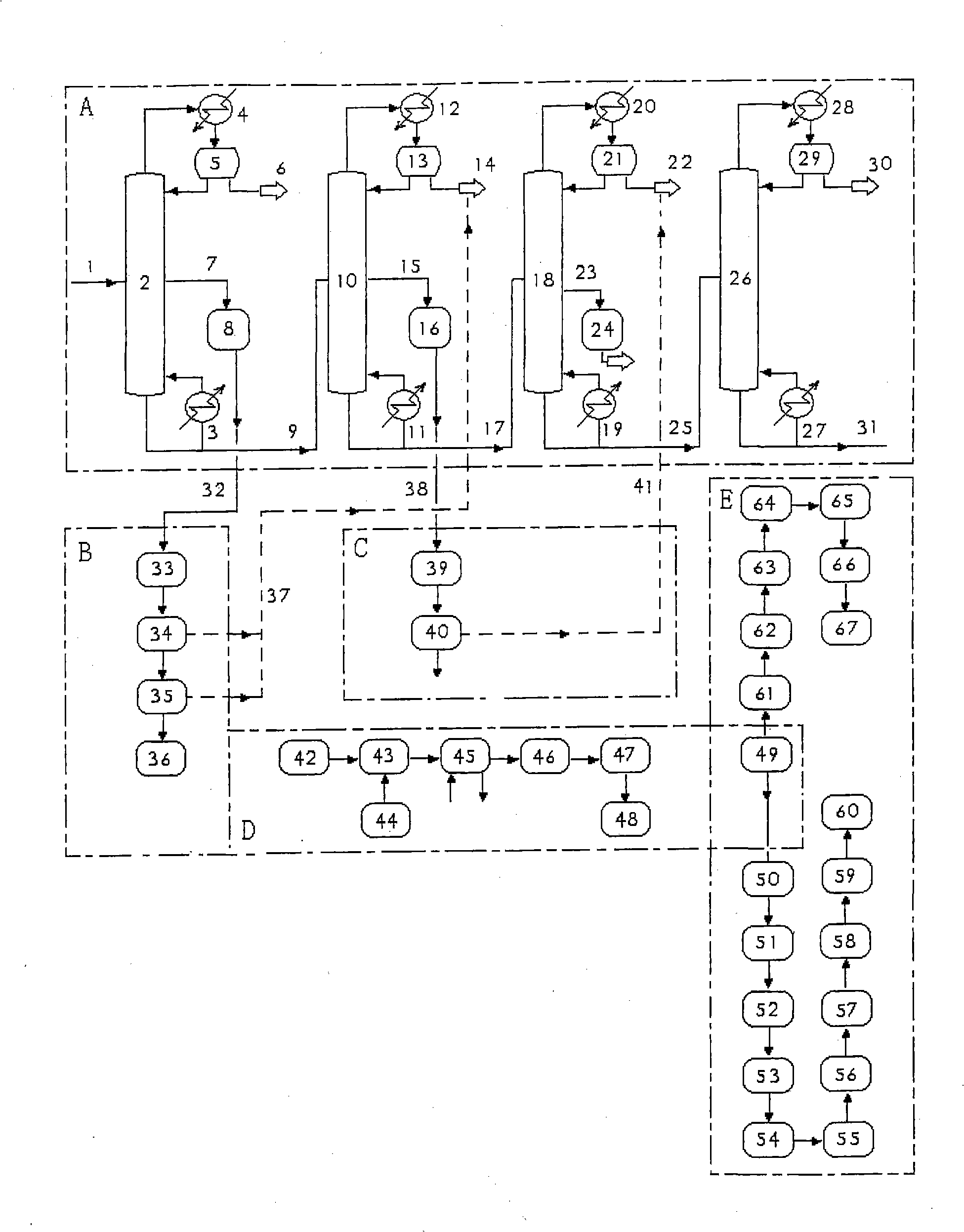

[0024] Please refer to the attached drawings, A, B, C, D and E marked in the drawings represent the five steps or processes of the method of the present invention.

[0025] A) C 10 Separation of heavy aromatics feedstock:

[0026] To be purchased from Sinopec Yangzi Petrochemical Co., Ltd. in Liuhe District, Nanjing City, Jiangsu Province, China 10 The heavy aromatic hydrocarbon raw material is introduced into the first rectification column 2 through the first pipeline 1 from the middle of the first rectification column 2 with a diameter of 1.6 m, a column height of 35 m and a plate number of 130 for rectification. The technological control condition of tower 2, namely rectification condition is: tower top temperature 115 ℃, tower top absolute pressure is 11kPa, reflux ratio 1: 11, the heat transfer oil temperature of first rectifying tower tower bottom reboiler 3 is 285 ℃, The top distillate of the first rectifying tower is condensed by the first tower top condenser 4 and t...

Embodiment 2

[0038] Please refer to the attached drawings, A, B, C, D and E marked in the drawings represent the five steps or processes of the method of the present invention.

[0039] Only C purchased from Sinopec Yangzi Petrochemical Co., Ltd. in Liuhe District, Nanjing City, Jiangsu Province, China. 10 The content of mesitylene of the heavy aromatic raw material is changed to 6.8%, and the process control conditions of the first rectifying tower 2, namely the rectification conditions, are changed to: the temperature at the top of the tower is 110.5°C, the absolute pressure at the top of the tower is 14.5kPa, the reflux ratio is 1:9, The temperature of the heat-conducting oil of the reboiler 3 at the bottom of the first rectifying tower is changed to 270 ° C; The temperature of the heat transfer oil of the reboiler 11 at the bottom of the second rectifying tower is changed to 279 °C; The temperature of the heat transfer oil of the bottom reboiler 19 of the third rectifying tower is cha...

Embodiment 3

[0047] Please refer to the attached drawings, A, B, C, D and E marked in the drawings represent the five steps or processes of the method of the present invention.

[0048] Only C purchased from Sinopec Yangzi Petrochemical Co., Ltd. in Liuhe District, Nanjing City, Jiangsu Province, China. 10 The content of mesitylene of the heavy aromatics raw material is changed to 6.5%, and the process control conditions of the first rectifying tower 2, namely the rectification conditions, are changed to: the temperature at the top of the tower is 127°C, the absolute pressure at the top of the tower is 14kPa, the reflux ratio is 1:10, and the The temperature of the heat transfer oil of the reboiler 3 at the bottom of the first rectifying tower is changed to 290 ° C; The temperature of the heat transfer oil of the reboiler 11 at the bottom of the rectifying tower is changed to 295 °C; The temperature of the heat transfer oil of the reboiler 19 at the bottom of the distillation tower is cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com