Method for preparing durene from methanol and xylene

A technology of mesitylene and xylene, applied in the field of preparation of mesitylene, can solve the problems of high reaction temperature and reaction pressure, high cost, and achieve the effects of reducing by-products, high stability and lowering reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

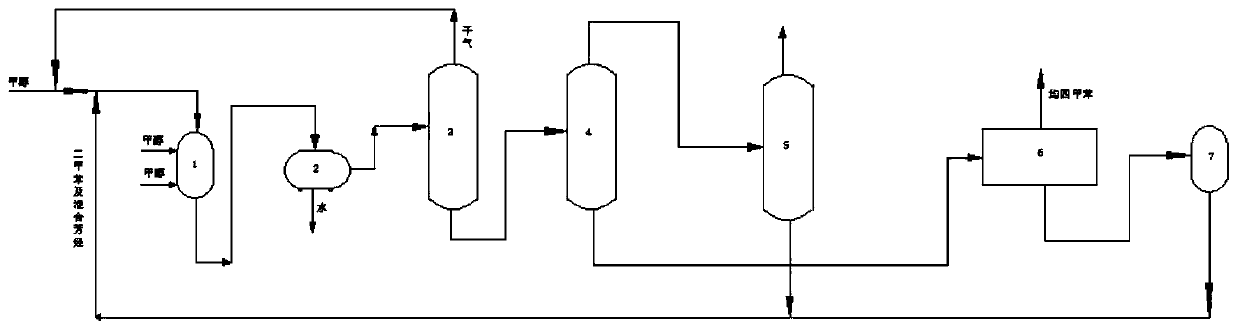

Image

Examples

Embodiment 1

[0038] Embodiment 1 Preparation of modified nanometer ZSM-5 molecular sieve catalyst

[0039] Mix the reaction raw materials 0.28g sodium metaaluminate, 0.44g sodium hydroxide and 21g deionized water evenly, add 10g silica sol and mix evenly, add 1.2g n-butylamine and mix evenly, then add 0.08g ZSM-5 seed crystals and mix evenly to form Mixed solution, put the mixed solution into a stirring tank, adjust the stirring rate to 300r / min, raise the temperature to 170°C to crystallize for 72 hours, and obtain a ZSM-5 molecular sieve carrier. The grain size of the ZSM-5 molecular sieve carrier is about 220nm, and 5g is obtained. The ZSM-5 molecular sieve carrier was impregnated with 0.5% sodium hydroxide solution at 80° C. for 2 hours, then exchanged with 0.4 M ammonium nitrate solution for 2 hours, and extruded. The extruded ZSM-5 was treated with 0.2M hydrofluoric acid solution at 40°C for 4h, impregnated with 0.05% zinc nitrate for 24h, and calcined at 550°C for 6h to obtain the m...

Embodiment 2

[0040] Embodiment 2 Preparation of modified nanometer ZSM-5 molecular sieve catalyst

[0041]Mix the reaction raw materials 0.31g sodium metaaluminate, 0.51g sodium hydroxide and 27g deionized water evenly, add 10g silica sol and mix evenly, add 1.48g n-butylamine and mix evenly, then add 0.06g ZSM-5 seed crystal and mix evenly, Form a mixed solution, place the mixed solution in a stirred tank, adjust the stirring rate to 300r / min, raise the temperature to 160°C for crystallization for 72 hours, and obtain a ZSM-5 molecular sieve carrier. The grain size of the ZSM-5 molecular sieve carrier is about 300nm. 5 g of the obtained ZSM-5 molecular sieve was treated with 0.4% sodium hydroxide solution at 80° C. for 2 hours, then exchanged with 0.5 M ammonium nitrate solution for 2 hours, and extruded. The extruded ZSM-5 was treated with 0.2M sulfuric acid solution at 50°C for 4 hours, impregnated with 0.04% copper nitrate for 24 hours, and calcined at 550°C for 6 hours to obtain a mod...

Embodiment 3

[0043] Mix the reaction raw materials 0.34g aluminum isopropoxide, 0.41g sodium hydroxide and 25g deionized water evenly, add 10g silica sol and mix evenly, add 0.87g n-butylamine and mix evenly, then add 0.09g ZSM-5 seed crystal and mix evenly, Form a mixed solution, put the mixed solution into a stirring tank, adjust the stirring rate to 300r / min, raise the temperature to 170°C to crystallize for 72 hours, and obtain a ZSM-5 molecular sieve. The grain size of the ZSM-5 molecular sieve carrier is about 210nm, and 5g is obtained. ZSM-5 molecular sieves were treated with 0.5% potassium hydroxide solution at 80°C for 2 hours, then exchanged with 0.6M ammonium nitrate solution for 1 hour, and extruded. The extruded ZSM-5 was treated with 0.2M nitric acid solution at 30°C for 4h, impregnated with 0.05% magnesium nitrate for 24h, and calcined at 550°C for 6h to obtain the modified nano ZSM-5 molecular sieve catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com