Method for extracting, distilling and separating acetonitrile-phenylmethane by utilizing dividing-wall rectifying tower

A separation wall rectification column and extractive rectification technology are applied in the field of separation of acetonitrile-toluene azeotrope mixture, which can solve the problems of difficult separation, many transition fractions and high cost, and reduce energy consumption, equipment investment and equipment investment. and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Raw materials (mass ratio: acetonitrile 80%, toluene 20%), extractant durene (99.9m%)

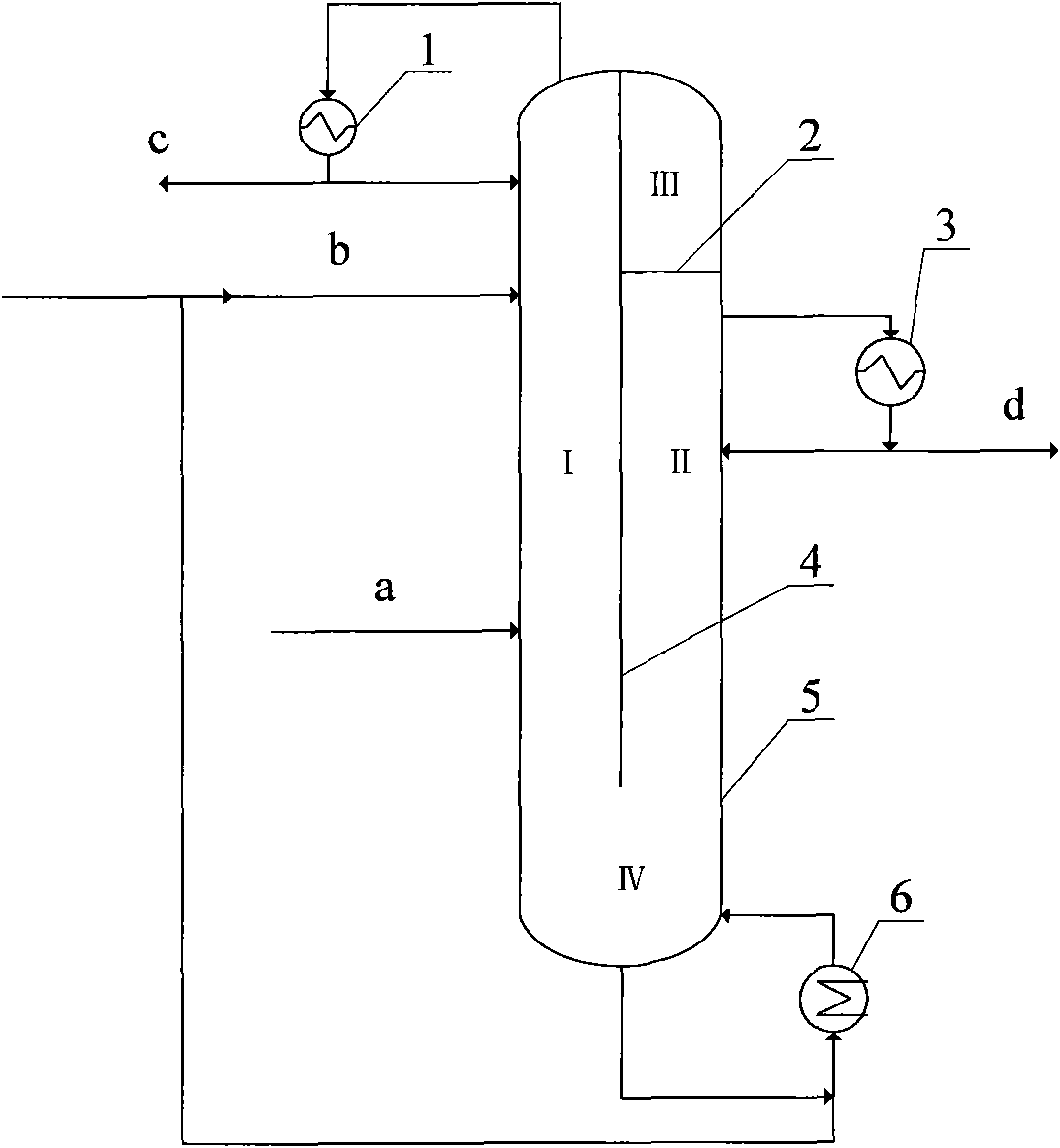

[0014] like figure 1 As shown, there are 50 theoretical plates in area I, 30 theoretical plates in area II, and 10 theoretical plates in area IV. After heating, the raw materials enter area I of the dividing wall rectification column, and the feeding position is the 30th theoretical plate , the extractant durene enters the sixth theoretical plate after being heated, high-purity acetonitrile is extracted from the top of the first area, toluene is extracted from the top of the second area, and the extractant is extracted from the bottom of the tower for recycling.

[0015] The operating conditions are as follows:

[0016] Pressure: 0.1MPa

[0017] The reflux ratio of zone I: 1.5:1

[0018] The reflux ratio of zone II: 2:1

[0019] Solvent ratio: 1:1

[0020] Acetonitrile toluene feed temperature: 60°C

[0021] Durene feed temperature: 90°C

[0022] The chromatographic analysis o...

Embodiment 2

[0039] Raw material (mass ratio: acetonitrile 80%, toluene 20%), extractant is propylbenzene (99.9m%)

[0040] like figure 1 As shown, there are 50 theoretical plates in area I, 30 theoretical plates in area II, and 10 theoretical plates in area IV. After heating, the raw materials enter area I of the dividing wall rectification column, and the feeding position is the 30th theoretical plate , the extractant propylbenzene enters the sixth theoretical plate after being heated, high-purity acetonitrile is extracted from the top of the first area, toluene is extracted from the top of the second area, and the extractant is extracted from the bottom of the tower for recycling.

[0041] The operating conditions are as follows:

[0042] Pressure: 0.1MPa

[0043] The reflux ratio of zone I: 3:1

[0044] The reflux ratio of zone II: 5:1

[0045] Solvent ratio: 3:1

[0046] Acetonitrile toluene feed temperature: 50°C

[0047] Propylene feed temperature: 80°C

[0048] Tower top pro...

Embodiment 3

[0065] Raw materials (mass ratio: acetonitrile 50%, toluene 50%), extractant durene (99.9m%)

[0066] like figure 1 As shown, there are 40 theoretical plates in area I, 20 theoretical plates in area II, and 10 theoretical plates in area IV. After heating, the raw materials enter area I of the dividing wall rectification column, and the feeding position is the 25th theoretical plate , the extractant durene enters the fifth theoretical plate after being heated, high-purity acetonitrile is extracted from the top of the I area, toluene is extracted from the top of the II area, and the extractant is extracted from the bottom of the tower for recycling.

[0067] The operating conditions are as follows:

[0068] Pressure: 0.1MPa

[0069] The reflux ratio of zone I: 0.5:1

[0070] The reflux ratio of zone II: 0.6:1

[0071] Solvent ratio: 0.8:1

[0072] Acetonitrile toluene feed temperature: 60°C

[0073] Durene feed temperature: 90°C

[0074] The chromatographic analysis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com