Method for capturing and purifying pyromellitic dianhydride

A technology of pyromellitic dianhydride and purification method, applied in separation methods, chemical instruments and methods, organic chemistry and other directions, can solve problems such as environmental pollution, difficulty in discharging, uneven heat transfer, etc., and achieves reduction of production costs, The effect of reducing the floor space and improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

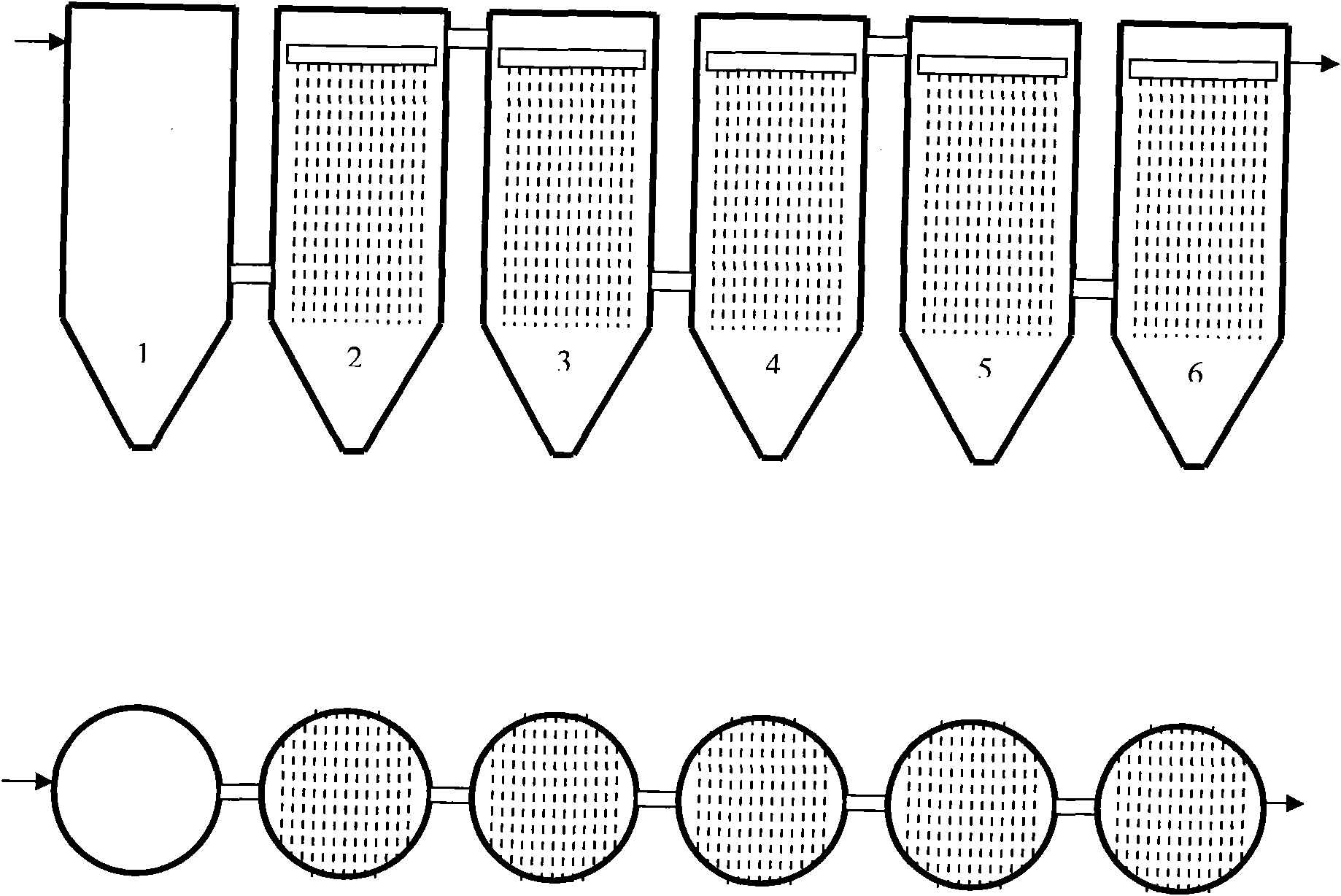

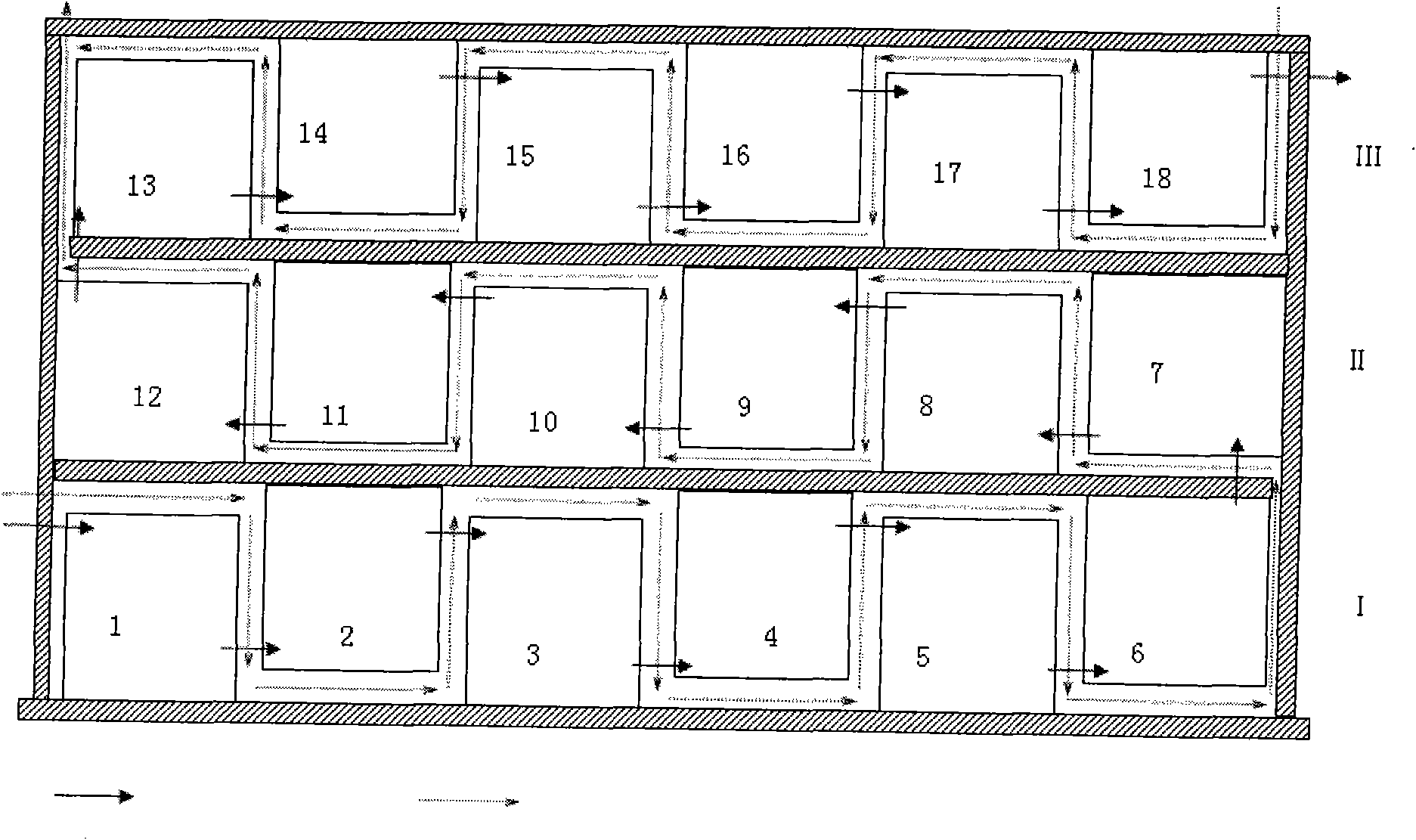

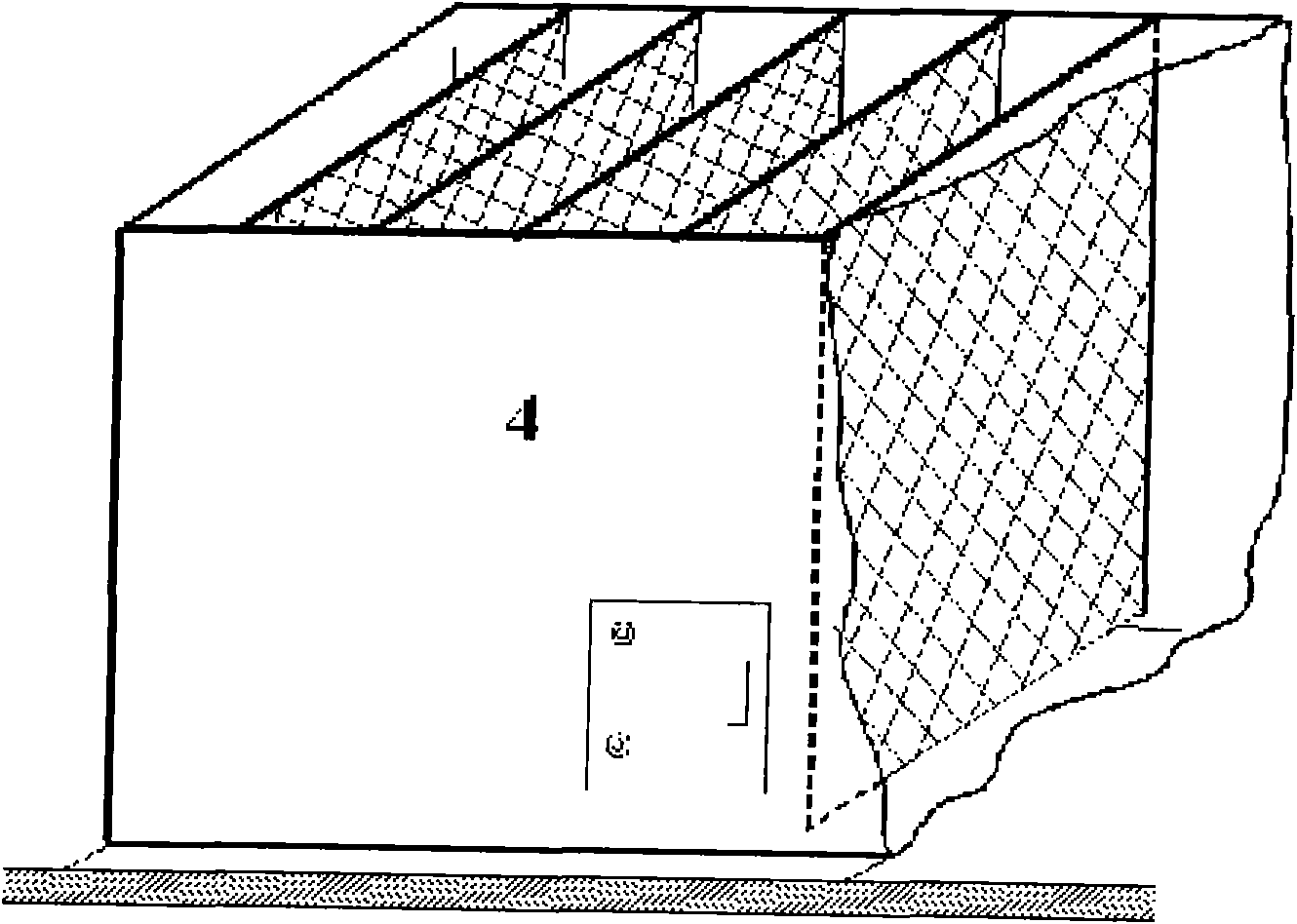

[0028] Such as figure 2 , image 3 As shown, gasified durene is mixed with air, and undergoes an oxidation reaction in a fixed-bed reactor equipped with a catalyst. h·L, the hot spot temperature is 435-445°C, and a mixed gas mainly composed of PMDA is generated, which contains a small amount of by-products such as TMA, PA, MAA, etc. After two heat exchanges, the temperature of the reaction product is controlled at 250°C. The box-type trap is composed of three layers of cuboids, which are the first, second, and third traps, with a total volume of 500m 3 , each trap is further divided into 6 trap units, the inside of each trap unit is the flow of the reaction product, the jacket layer is the air for cooling, and the heat exchange is carried out in the way of downstream heat exchange. The air after heat exchange is directly emptied from the jacket layer of the third trap, and most of the reaction products are desublimated and crystallized in the first and second traps after he...

Embodiment 2

[0032] After gasification, durene is mixed with air, and undergoes oxidation reaction in a fixed-bed reactor equipped with a catalyst, with a space velocity of 5000-5500L / h·L, a molten salt temperature of 380-385°C, and a load of 60-70g / h· L, the hot spot temperature is 435-445°C, and a mixed gas mainly composed of pyromellitic dianhydride is generated, which contains a small amount of by-products such as TMA, PA, MAA, etc. After two heat exchanges with air, the inlet temperature of the trap is controlled to 250 ℃.

[0033] The reaction product enters the trapping device and is cooled down by the normal temperature air in the jacket layer. After entering the first trap, the temperature of the reaction product is controlled at 165-175°C. The gas phase reaction product is in contact with the suspended metal mesh, and PMDA is in the metal mesh. Surface desublimation crystallization forms many new crystallization centers, promotes the rapid growth and crystallization of PMDA in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com