Production technique of benzenetetracarboxylic dianhydride by catalyzing carrier-type polyoxometalates

A technology of pyromellitic dianhydride and polyoxometalate, which is applied in the field of carrier-type polyoxometalate catalyzed production of pyromellitic dianhydride, and can solve the problems of difficulty, pollution of the production process of pyromellitic anhydride, and high production cost problem, to achieve the effect of low production cost, avoid equipment corrosion, and reduce raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

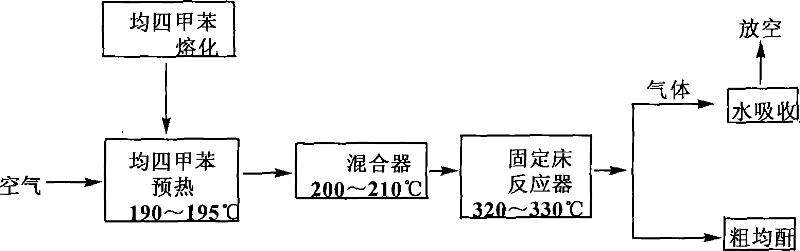

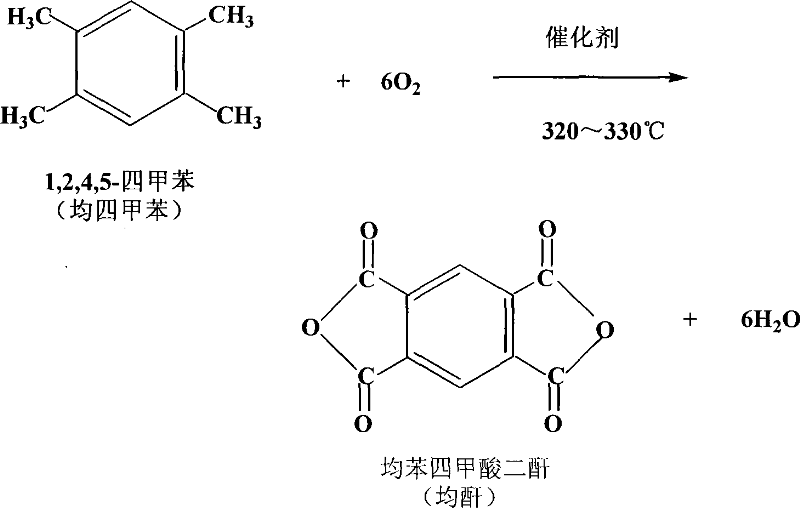

[0019] Melt durene at 190°C in the material tank, preheat and send it to the mixer for vaporization at 200°C, the feed concentration is 17.0-17.5g / m 3 , mixed with air, the mixed gas enters the fixed-bed reactor for oxidation, and at 320°C, the catalyst is polymetallic oxo-acid (POM) loaded and fixed on the catalytic bed, poly-metallic oxo-acid: (C 21 h 37 NH) 3 h 3 AsMo 9 V 3 o 40 / SiO 2 The mass ratio to durene is 5‰, and the space velocity is 6500h -1 carry out the oxidation reaction. The gas after the reaction is cooled and solidified in the trap to obtain crude pyromellitic dianhydride.

Embodiment 2

[0021] Melt durene at 193°C in the feed tank, preheat and send it to the mixer for vaporization at 205°C, the feed concentration is 15.5g / m 3 , mixed with air, the mixed gas enters the fixed bed reactor for oxidation, and at 340°C, the catalyst is polyoxometalate (POM) loaded and fixed on the catalytic bed, polyoxometalate (C 21 h 37 NH) 3 h 2 AsMo 10 V 2 o 40 / SiO 2 The mass ratio to durene is 8‰, and the space velocity is 4500h -1 carry out the oxidation reaction. The gas after the reaction is cooled and solidified in the trap to obtain crude pyromellitic dianhydride.

Embodiment 3

[0023] Melt durene at 195°C in the material tank, preheat and send it to the mixer for vaporization at 210°C, the feed concentration is 19.5g / m 3 , mixed with air, the mixed gas enters the fixed bed reactor for oxidation, and at 320°C, the catalyst is polyoxometalate (POM) loaded and fixed on the catalytic bed, polyoxometalate (C 21 h 17 NH) 3 HAsMo 11 VO 40 / SiO 2 The mass ratio to durene is 6‰, and the space velocity is 6500h -1 carry out the oxidation reaction. The gas after the reaction is cooled and solidified in the trap to obtain crude pyromellitic dianhydride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com