Preparation method and application of modified HZSM-5 molecular sieve catalyst

A catalyst and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve problems such as unfavorable operation of automobile engines, increased carbon dioxide emissions, low gasoline octane number, etc. Effects on gas diffusion, high gasoline selectivity, high octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, the preparation of modified HZSM-5 molecular sieve catalyst

[0042] (1), the SiO 2 / Al 2 o 3=100 nano-aggregates HZSM-5 molecular sieve (the size of the basic particles forming the nano-aggregates is 10-50nm), pseudo-boehmite, nitric acid, water, methylcellulose, polyethylene glycol, Tween-60 Mix evenly according to the mass ratio of 1:0.3:0.05:0.5:0.01:0.005:0.005, extrude into a cylindrical strip with a diameter of 1 to 3mm through extrusion equipment, and then dry, break, and roast to obtain a length of 10 Catalyst precursors of ~30 mm cylindrical morphology.

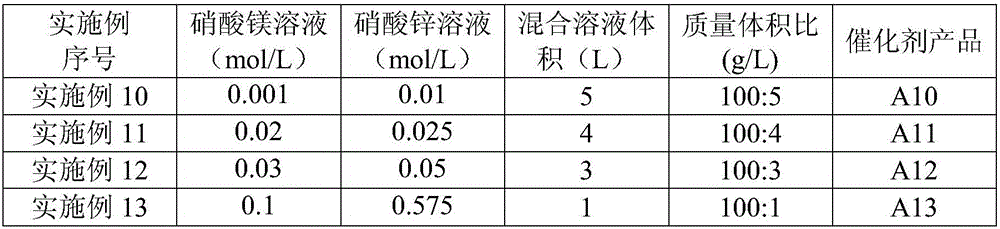

[0043] (2) Weigh 100g of the catalyst precursor obtained in step (1) and add it to 1L of a mixed solution of 0.01mol / L magnesium nitrate and 0.02mol / L zinc nitrate, and slowly stir and impregnate at 60±10°C for 12±2 hours , the stirring speed is 30 rpm, and then decompress and spin dry the water in a rotary evaporator under the condition of 80±5°C water bath, then dry at 120±10°C for 5±0.5 h...

Embodiment 2-6

[0044] Embodiment 2-6, preparation of modified HZSM-5 molecular sieve catalyst

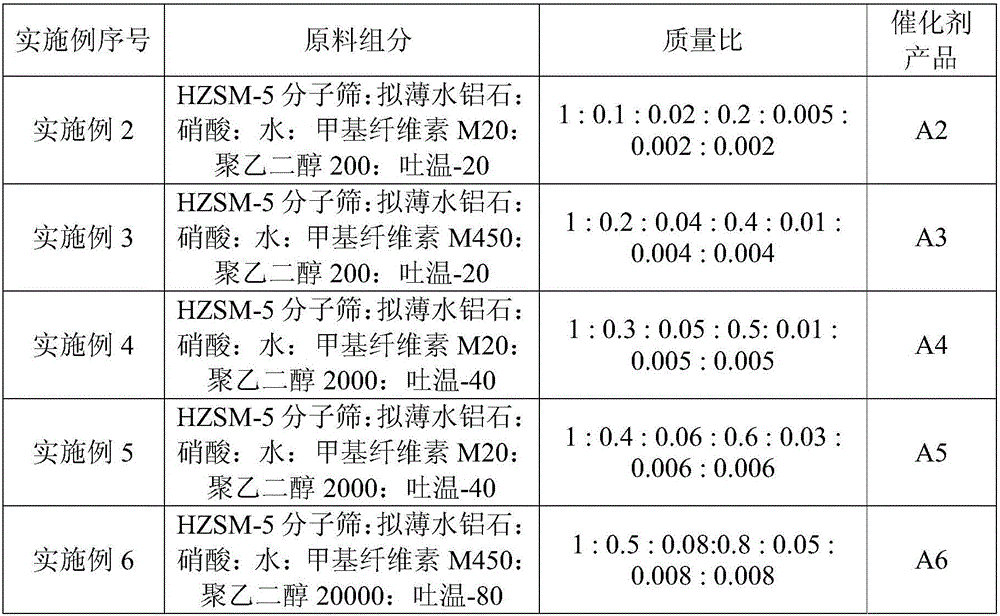

[0045] Preparation of modified nano-agglomerated HZSM-5 molecular sieve catalysts with different raw material components and mass ratios, SiO of HZSM-5 molecular sieves 2 / Al 2 o 3 =20, all the other steps are the same as in Example 1 to obtain catalysts A2-A6.

[0046] The raw material components and quality ratios of Examples 2-6 are shown in Table 1.

[0047] Table 1 HZSM-5 molecular sieve catalytic raw material components and mass ratio

[0048]

Embodiment 7-9

[0049] Embodiment 7-9, preparation of modified HZSM-5 molecular sieve catalyst

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com