A kind of preparation method of multi-layer il@mof composite film

A multi-layer composite membrane and composite membrane technology, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of low flux of polymer membranes and restrict industrial development, and achieve high flux, good mechanical strength, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

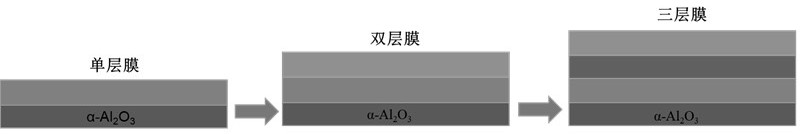

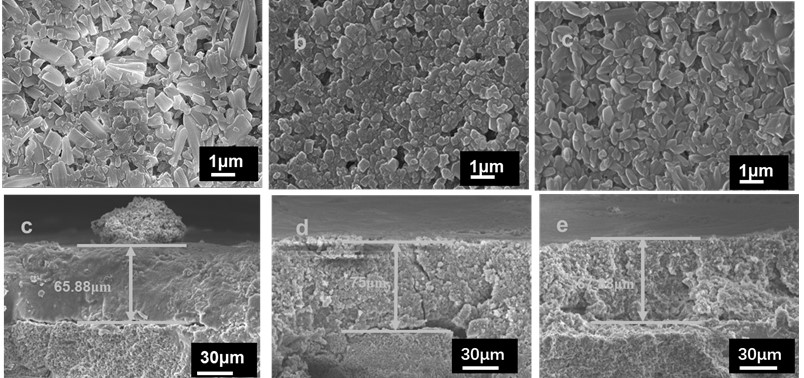

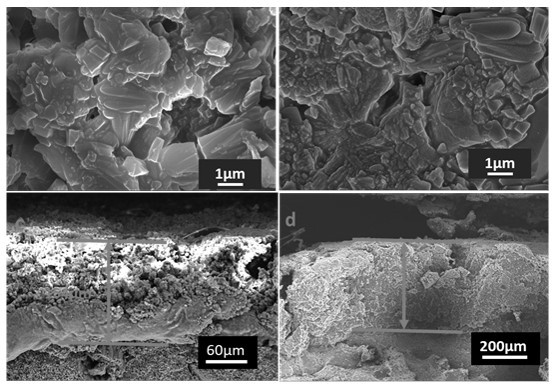

Image

Examples

example 1

[0029] Each single-layer composite membrane and bilayer and triple-layer membranes will be prepared for H 2 , CO 2 、CH 4 , N 2 The pure group of gases is tested for permeation to obtain the gas flux.

[0030] Place the [TETA]L@MOF film in the mold respectively, seal it well, and measure the H 2 , CO 2 、CH 4 , N 2 , it is necessary to keep the gas circulating for more than 2 h before each measurement to ensure that no other gas affects the experimental results. Then use a soap bubble flowmeter to test the gas flux after the gas passes through the membrane and test the gas flux of the membrane under different pressure drops for comparison. After the measurement, the durability of the membrane was detected, and the gas flow was maintained for 100 h to judge the durability of the membrane.

example 2

[0032] Each single-layer composite membrane and bilayer and triple-layer membranes will be prepared for H 2 / CO 2 、CH 4 / CO 2 , N 2 / CO 2 The mixed gas is used for permeation test to obtain gas flux and separation selectivity.

[0033] Place the [TETA]L@MOF film in the mold respectively, seal it well, and open the H 2 and CO 2 Two gas cylinders are used to maintain the same inlet pressure and flow rate of the two gases. Before each measurement, the two gases need to be kept in circulation for more than 2 hours to ensure that no other gases affect the experimental results. Then use He as the protective gas to load the mixed gas sieved through the membrane into the gas chromatograph, and the gas chromatograph detects the proportion of the two gases to be tested, and calculates the gas flux of the two gases to be tested, and then tests The gas fluxes of the membranes at different pressure drops were compared. Test CH sequentially as above 4 / CO 2 and N 2 / CO 2 mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com