A carbon dioxide separation membrane and its application

A carbon dioxide and separation membrane technology, applied in the field of membrane separation, can solve the problems of membrane defects, easy agglomeration, poor dispersion uniformity, etc., and achieve the effect of improving stability and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

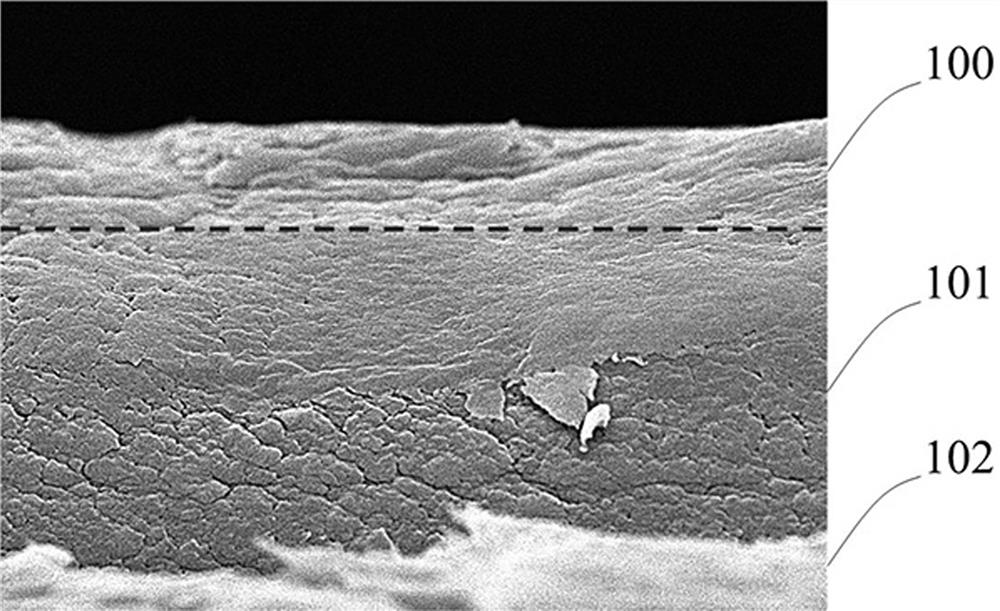

Image

Examples

preparation example Construction

[0106] The preparation method of caged crown ether adsorption modified graphene in the embodiment of the present invention comprises the following steps:

[0107] Dissolve 18-crown-6 (CAS number: 17455-13-9; Hubei Kewode Chemical Co., Ltd.) in water to prepare a 18-crown-6 solution with a mass concentration of 0.01%~0.1%, and adjust it with hydrochloric acid The pH value of the solution is 2~3.

[0108] Put graphene in the prepared 18-crown-6 aqueous solution, stir at high speed (8000rmp~10000rpm) for 0.5h~1h at room temperature (20°C~30°C), then stir at low speed (500rmp~700rpm) for 8h~10h, Graphene is uniformly dispersed and saturated to adsorb 18-crown-6; a suspension containing 18-crown-6 and graphene is prepared.

[0109] The suspension containing 18-crown-6 and graphene is subjected to spray freeze-drying, and the freeze-drying temperature is -50~-30° C. to prepare 18-crown-6 modified graphene.

[0110] The preparation method of DL-2-amino-1-butanol adsorption modified...

Embodiment 1

[0116]This embodiment is a method for preparing a carbon dioxide separation membrane, comprising the following steps:

[0117] S1. Under high-speed shear (10000rpm), disperse 200.0g of cage-shaped crown ether-modified graphene (D50 is 10nm) in 790g of N, N-dimethylformamide (DMF), and stir for 2 hours to obtain cage-shaped crowns. Ether modified graphene dispersion;

[0118] Then, 10 g of polyvinylidene fluoride (solvay, PVDF9009) was added to the crown ether-modified graphene dispersion, stirred and heated to 80° C. to dissolve, and the dissolution time was 4 hours to obtain caged crown ether-modified graphene / polyvinylidene fluoride blend casting. Membrane solution: Vacuum defoam the graphene / polyvinylidene fluoride blend casting solution (degassing pressure is 50kPa), and cool to room temperature (about 25°C).

[0119] S2, the graphene / polyvinylidene fluoride blend casting film modified by the caged crown ether prepared in step S1 adopts the slit coating method (using a me...

Embodiment 2

[0129] This embodiment is a method for preparing a carbon dioxide separation membrane, comprising the following steps:

[0130] S1. Under high-speed shear (10000rpm), disperse 150.0g of caged crown ether-modified graphene (D50 is 10nm) in 842.5g of N,N-dimethylformamide (DMF), and stir for 2h to obtain a cage Crown ether modified graphene dispersion;

[0131] Then, 7.5 g of polym-phenylene isophthalamide (Yantai Taihe New Materials Co., Ltd.) was added to the cage-shaped crown ether-modified graphene dispersion, stirred and heated to 80°C for 4 hours to obtain a cage-like Crown ether modified graphene / polym-phenylene isophthalamide blend casting solution. Vacuum defoam the casting solution (degassing pressure is 60kPa), and cool to room temperature (about 25°C).

[0132] S2, the graphene / poly-m-phenylene isophthalamide blended film casting liquid that the cage crown ether modification prepared in step S1 is evenly coated on the porous aramid fiber cloth (DuPont TYVEK, Pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com