A class of glassy MOF membrane material with hydrogen separation properties and preparation method thereof

A glassy, membrane material technology, applied in the field of membrane-based gas separation and glassy MOF membrane gas separation, to achieve the effect of high hydrogen flux, simple operation and high separation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

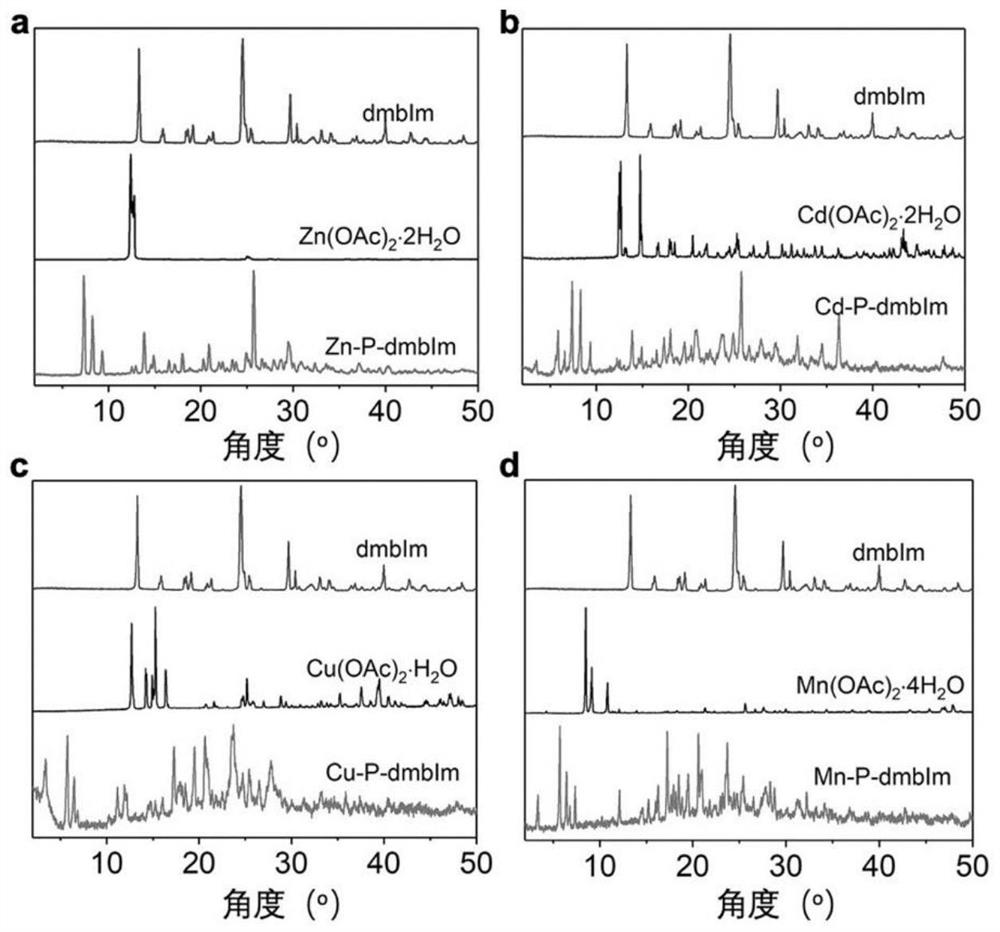

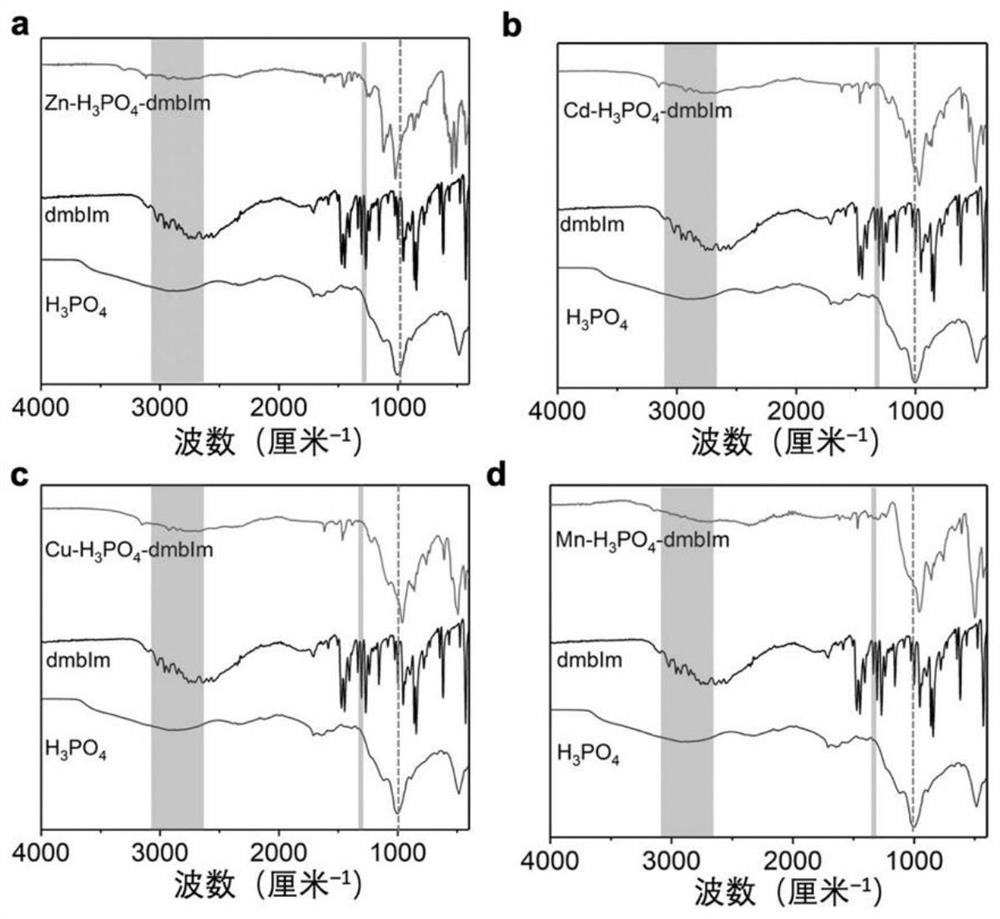

[0026] The concrete preparation method of the glassy MOF film material that dmbIm, phosphoric acid and zinc oxide are formed is as follows:

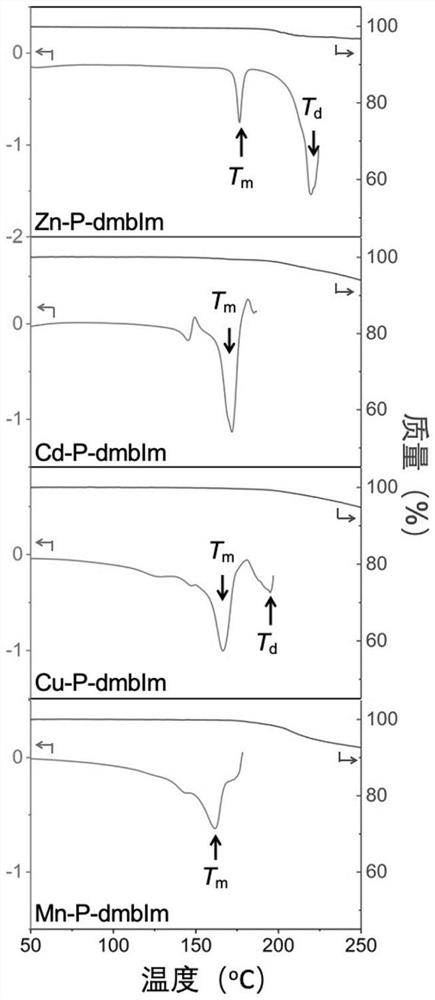

[0027] Put dmbIm, phosphoric acid and zinc oxide in a mortar, add quantitative ethanol, grind for half an hour, wash the obtained solid with dichloromethane, and dry to obtain Zn-P-dmbIm material. The obtained MOFs material was pressed into tablets to obtain a 2cm-diameter sheet, which was put into a tube furnace for calcination at 210°C for 0.5h, and a glassy Zn-P-dmbIm film was obtained after cooling.

Embodiment 2

[0029] The concrete preparation method of the glassy MOF membrane material that dmbIm, phosphoric acid and cadmium acetate are formed is as follows:

[0030] Put dmbIm, phosphoric acid and cadmium acetate in a mortar, add a certain amount of ethanol, grind for half an hour, wash the obtained solid with dichloromethane, and dry to obtain a Cd-P-dmbIm material. The obtained MOFs material was pressed into tablets to obtain a 2cm-diameter sheet, which was put into a tube furnace for calcination at 200°C for 1 hour, and a glassy Cd-P-dmbIm film was obtained after cooling.

Embodiment 3

[0032] The concrete preparation method of the glassy MOF membrane material that dmbIm, phosphoric acid and copper acetate are formed is as follows:

[0033] Put dmbIm, phosphoric acid and copper acetate in a mortar, add quantitative ethanol, grind for half an hour, wash the obtained solid with dichloromethane, and dry to obtain Cu-P-dmbIm material. The obtained MOFs material was pressed into tablets to obtain a 2cm-diameter sheet, which was put into a tube furnace for calcination at 190°C for 0.75h, and a glassy Cu-P-dmbIm film was obtained after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com